Method for inspecting and controlling dyeing liquid component of dyeing machine on-line

A dyeing machine and dye liquor technology, applied in ratio control, chemical variable control, non-electrical variable control, etc., can solve the problems of large influence on dyeing quality, responsibility of dyeing control personnel, color difference before and after dyeing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

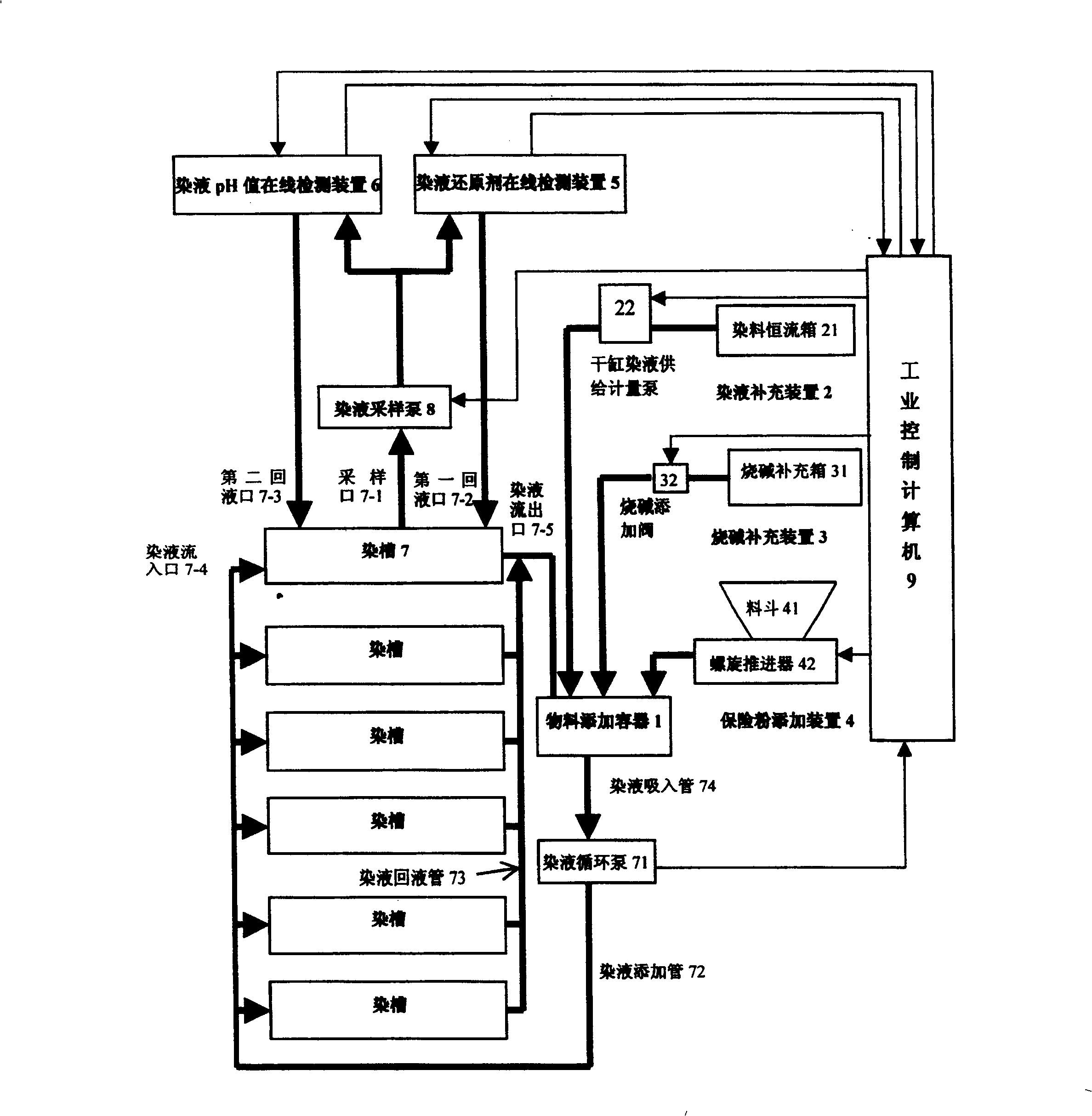

[0024] See figure 1 , step ① of the method of this embodiment is to set up an online detection and control system. The system has a dye liquor component adding device, a dye liquor reducing agent online detection device 5, a dye liquor pH value online detection device 6, a dye liquor sampling pump 8 and a circuit device. The dye liquor component adding device has a dye liquor replenishing device 2 , a caustic soda replenishing device 3 and a hydrosulfite adding device 4 . The circuit arrangement has an industrial control computer 9 . The on-line detection and control system also has a material addition container 1 arranged in the dye liquor circulation loop of the dyeing machine.

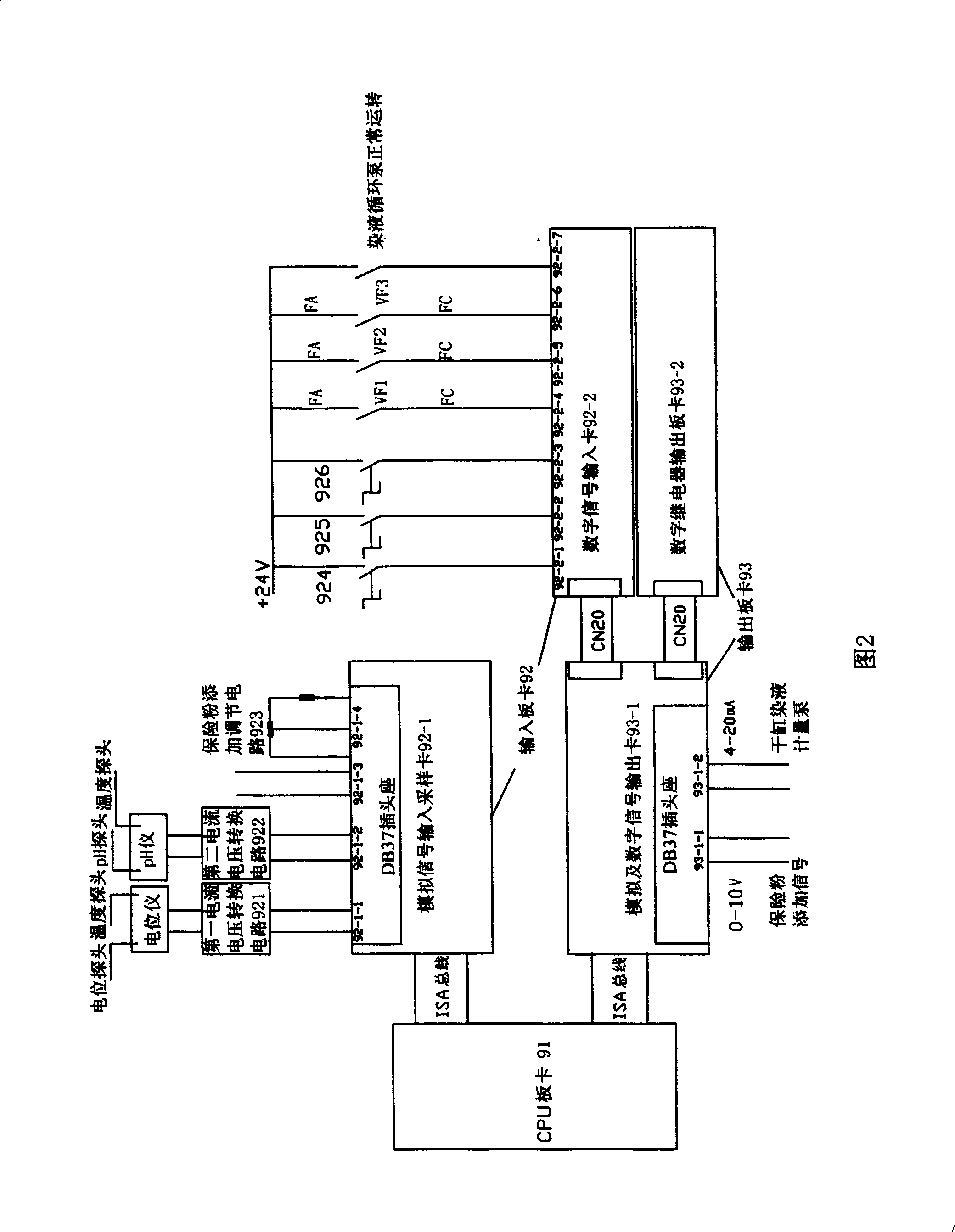

[0025] 2, the industrial control computer 9 has a CPU board 91, an input board 92 and an output board 93 controlled by the CPU board 91, and also has an LCD display, a mouse, a keyboard, and a display card. The input board 92 is composed of an analog signal input sampling card 92-1 and a digital ...

Embodiment 2

[0071] See Fig. 6 and Fig. 7, others are the same as embodiment 1, the difference is that: the online detection and control system of this embodiment is used in the ball warp dyeing machine. Therefore, compared with Embodiment 1, there are certain changes in the connection relationship of related equipment and components. Among them, the dye constant flow box 21 in the system is connected to the dye solution suction pipe 74 at the suction port of the dye solution circulation pump 71 through the filter, the dry vat dye solution supply metering pump 22 and the valve in sequence; the material addition container 1 is a material addition tank; The material adding tank 1 has a hydrosulfite adding port, a caustic soda solution adding port, a dye liquor output port and a dye liquor return port. The dye solution output port of the material adding tank 1 is connected with the dye solution circulating pump 71 through the valve, the dye solution suction pipe 74 and the filter screen succe...

Embodiment 3

[0081] Other processes are the same as in Example 1, except that the dye in the dye solution is magenta.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com