Device for assembling, tuning, and testing motor vehicles.

A technology for assembly workshops and equipment, which is applied in the field of equipment and assembly for adjusting and testing vehicles, and can solve problems such as unusable winter tires, multi-manpower input, and maximum speed of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

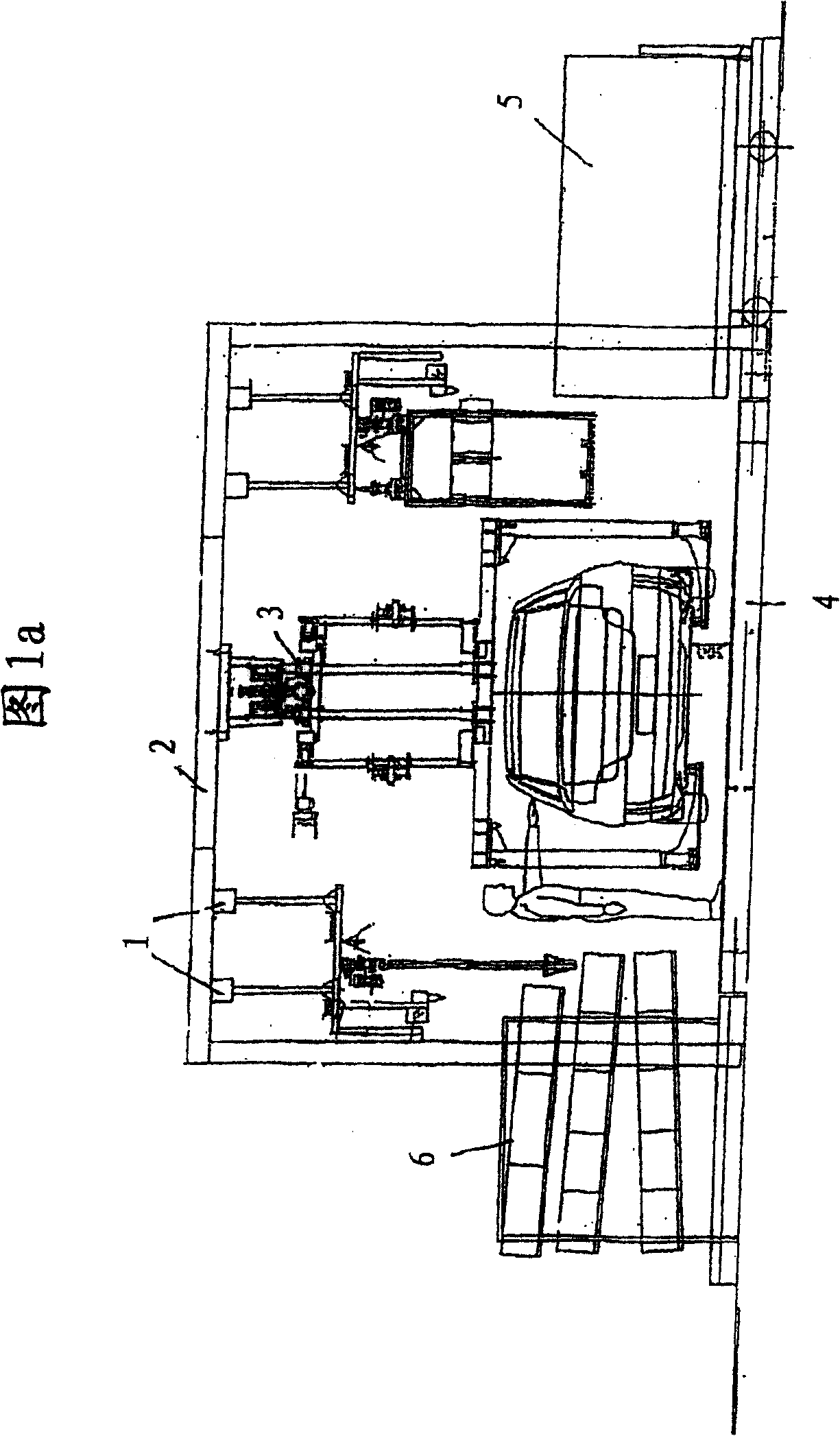

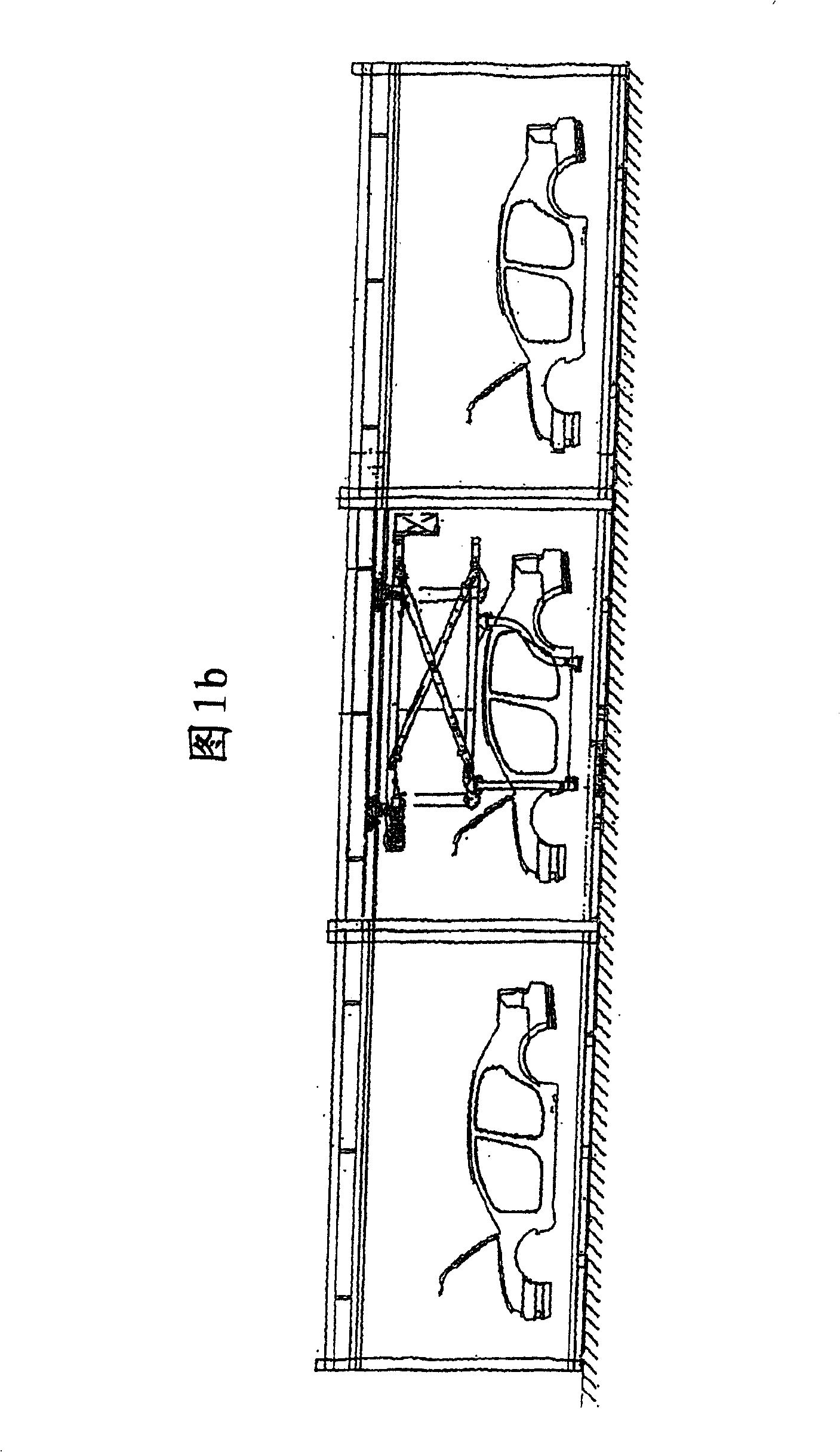

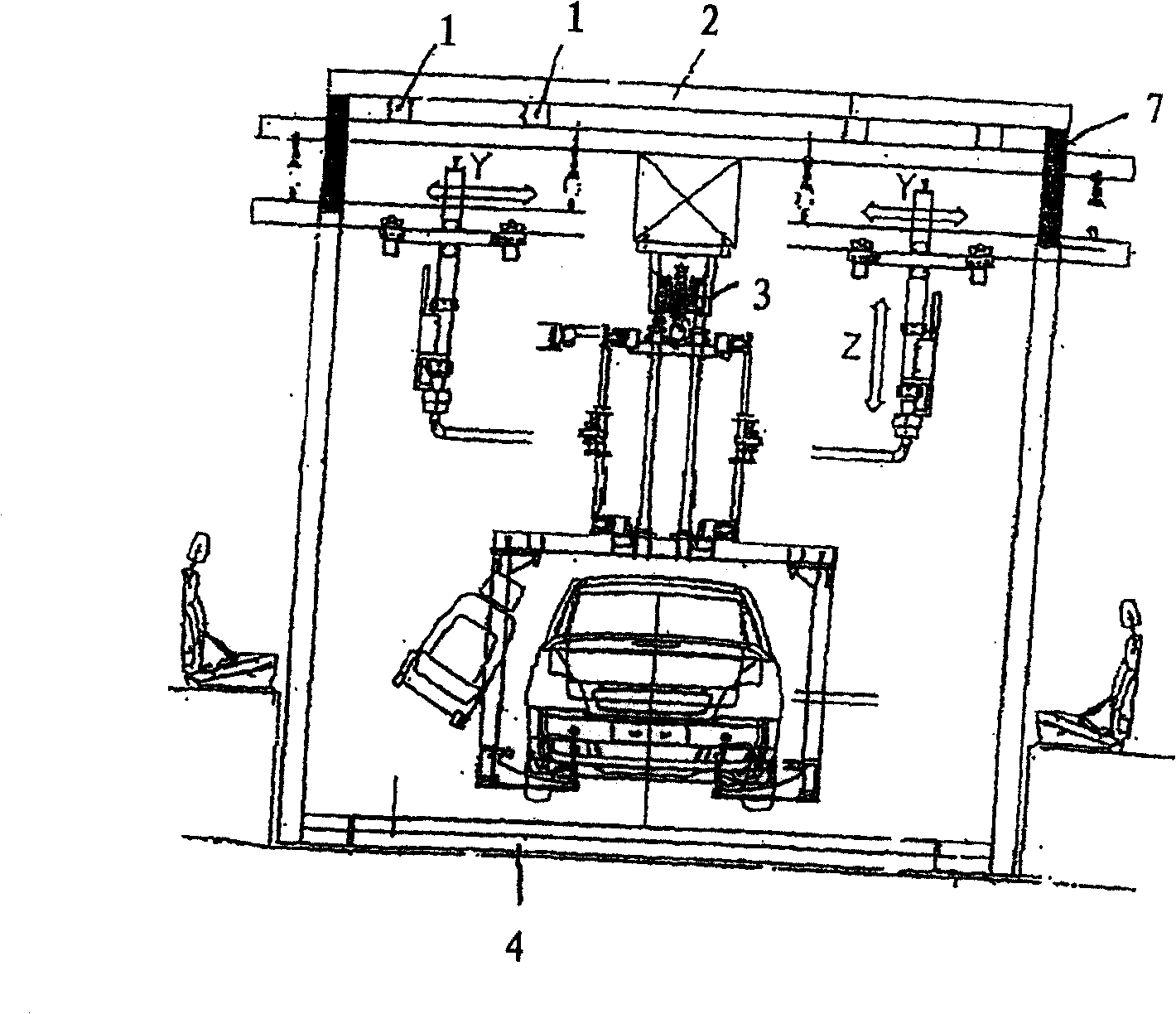

[0042]As can be seen from FIGS. 1a and 1b, the individual units (“modular workstations”) have a load-bearing structure comprising longitudinal beams 1 and cross beams 2, on which transport devices 3 for the vehicle to be assembled and, for example, electrical and data lines and Supply lines such as gas lines and other devices such as ropes for signage and tram tracks and pneumatic devices. For supply lines, especially energy supply lines, quick connectors are provided at the connection positions between two units, which ensure the energy supply from unit to unit. In this way, it is possible to connect one of the units to the supply line in the workshop and supply the other units along with it via quick couplings, without the need for complex individual connections for all the units. Of course, the individual units can also be connected individually to the supply line.

[0043] In addition, each unit also has a workshop accompanying belt 4 or an alternative site platform. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com