Method and device for supplying different temperature beat conductive using same parameter heat conductive oil furnace

A technology of heat-conducting oil and heating furnace, which is applied in the direction of melting and processing tar asphalt/petroleum asphalt/natural asphalt, etc. It can solve the problems of different specifications, heat-conducting oil furnaces cannot be used as backup for each other, and increase investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

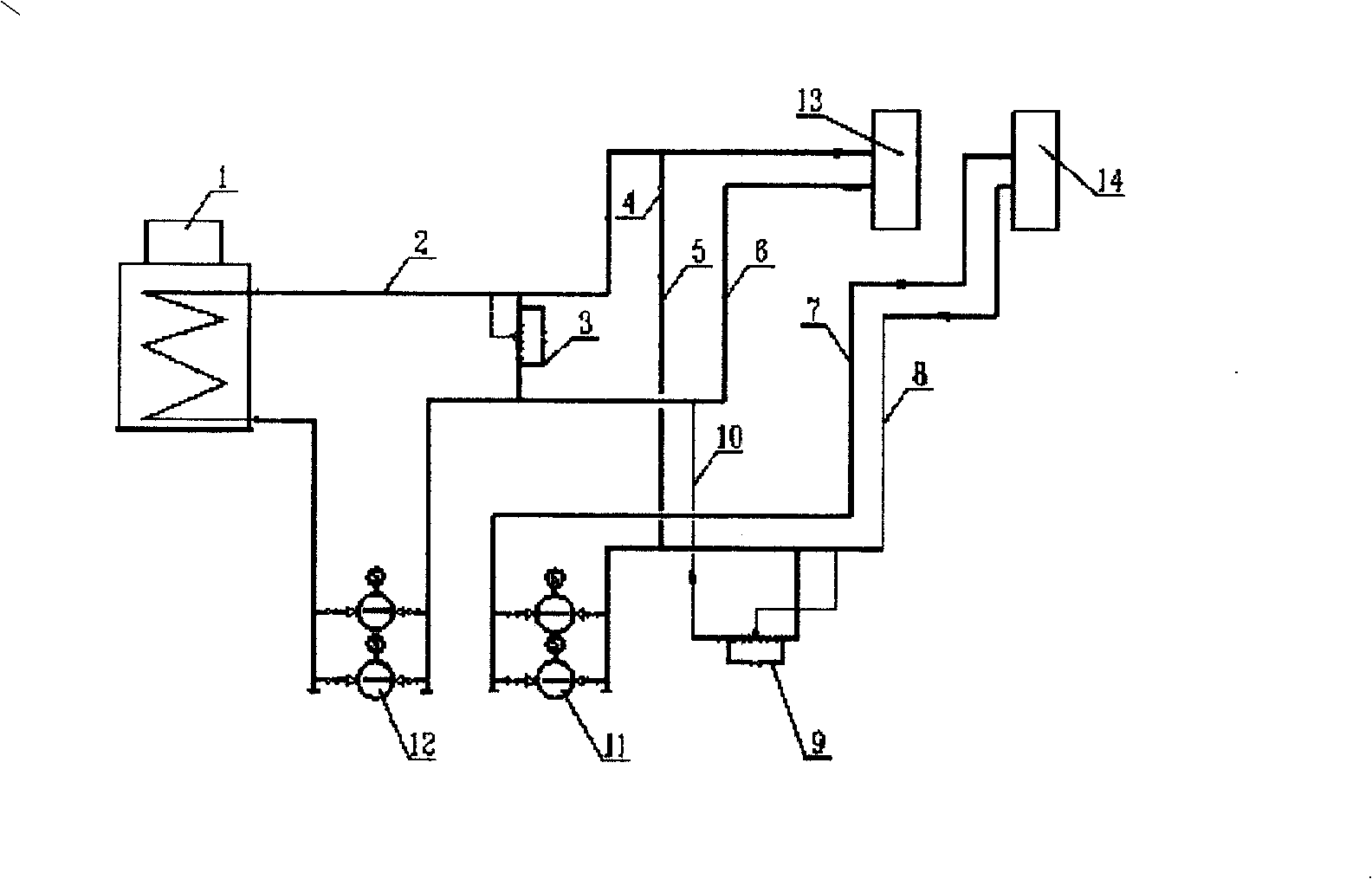

[0010] Embodiment 1 of the present invention: as figure 1 As shown, when there are few heat-consuming equipment and the heat consumption of the system is small, a heat-conducting oil heating furnace (1) is used to supply heat-conducting oil, and the high-temperature system oil supply pipe (2) of the high-temperature heat-consuming equipment (13) and the high-temperature system return The oil pipe (6) is connected to the heat transfer oil heating furnace (1), and a high-temperature circulation pump (12) is installed on the oil return pipe (6) of the high-temperature system, and the oil supply pipe (2) of the high-temperature system and the oil return pipe (6) of the high-temperature system Connect the heat transfer oil and the oil inlet and outlet temperature adjustment device (3) of the heat transfer oil heating furnace; connect the oil supply pipe (7) of the low temperature system and the oil return pipe (8) of the low temperature system to the low temperature heating equipmen...

Embodiment 2

[0011] Embodiment 2 of the present invention: when there are many heat-consuming equipment and the system consumes a lot of heat, more than one heat-conducting oil heating furnace with the same parameters is used to supply the heat-conducting oil, and its equipment configuration is the same as that in Embodiment 1. In this way, no matter how many temperatures of heat-conducting oil are required by the heat-using equipment, no matter how much heat is at various temperatures, the heat-conducting oil heating station only needs to determine the capacity of the heat-conducting oil heating furnace according to the total heat load, and a heat-conducting oil heating station can completely The use of heat conduction oil heating furnace with the same parameters makes operation and maintenance simple, spare parts are reduced, and the equipment is highly interchangeable. When a certain equipment fails, the supply of heat conduction oil at a certain temperature will not be stopped, ensuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com