Novel elastic alloy material

An elastic alloy, weight percentage technology, applied in the field of materials, can solve the problems of increasing the manufacturing cost of glasses, high consumption, rising prices of nickel-containing alloy materials, etc., achieving excellent tensile strength and elongation, reducing nickel consumption and reducing manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Continuous casting

[0020] Use materials that meet the requirements: 226.55kg of copper, 78kg of zinc, 191kg of nickel, 1.6kg of iron, and 2.3kg of manganese to make a charge that meets the product composition requirements. Sampling was carried out for chemical composition analysis in front of the furnace. The alloy composition percentages obtained after melting the charge made by the above formula are as follows: 45.31% copper, 15.6% zinc, 38.2% nickel, 0.32% iron, 0.46% manganese, and 0.11% impurities.

[0021] After completing the pre-furnace analysis and confirming that the molten metal meets the product requirements, continue to heat the molten metal to 1300-1400°C, carefully remove slag and add covering agent. Start the horizontal continuous casting tractor, and the continuous casting products are taken up by the winder behind the continuous casting tractor.

[0022] 2. Stretch

[0023] Continuous casting products are made into products required by users aft...

Embodiment 2 10

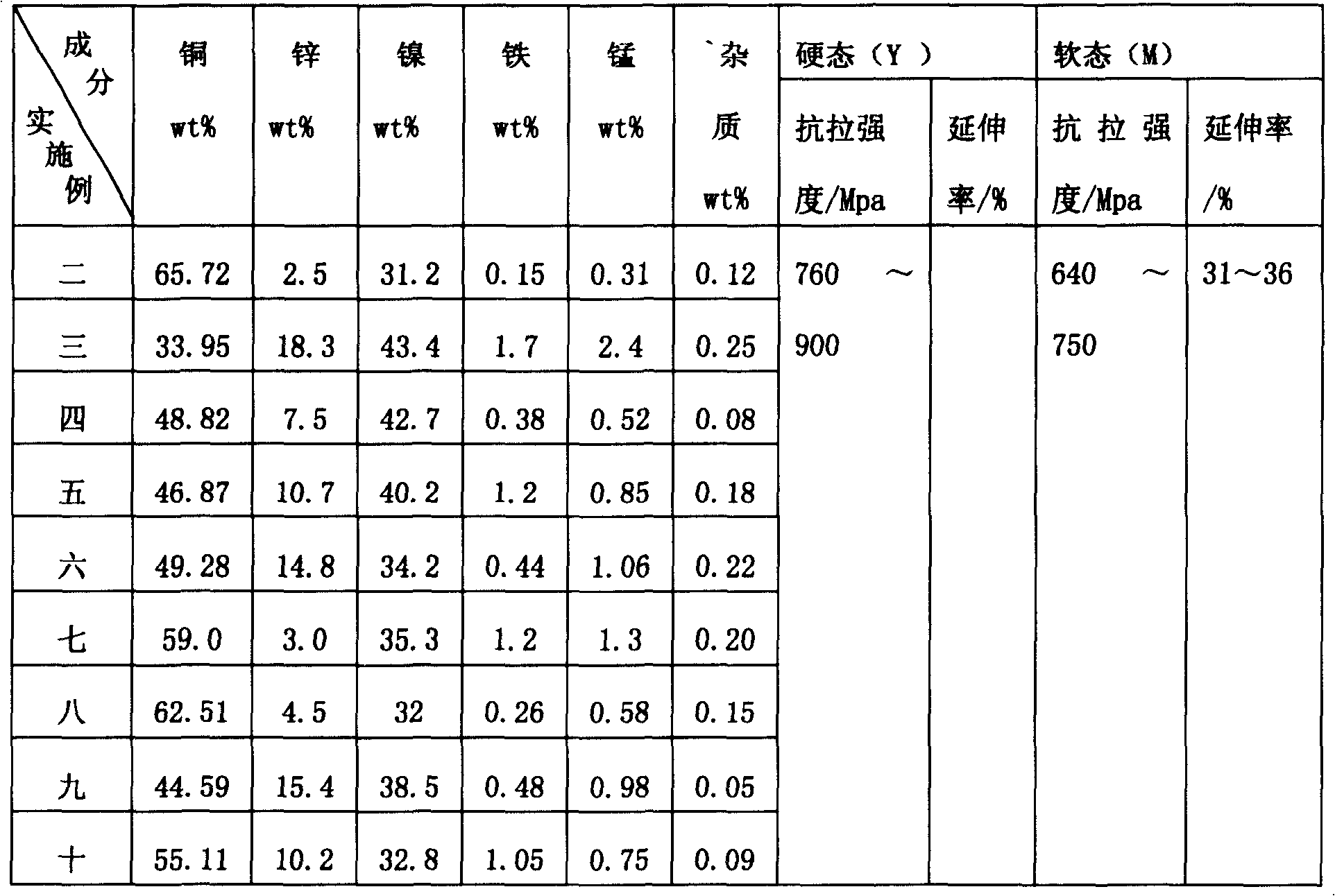

[0032] The basic principles and processes of Embodiments 2 to 10 are the same as those in Embodiment 1. The difference is that the proportions of each component in the alloy are different. With reference to Table 2, it is the product components and their properties of φ4.1mm in each embodiment. parameter.

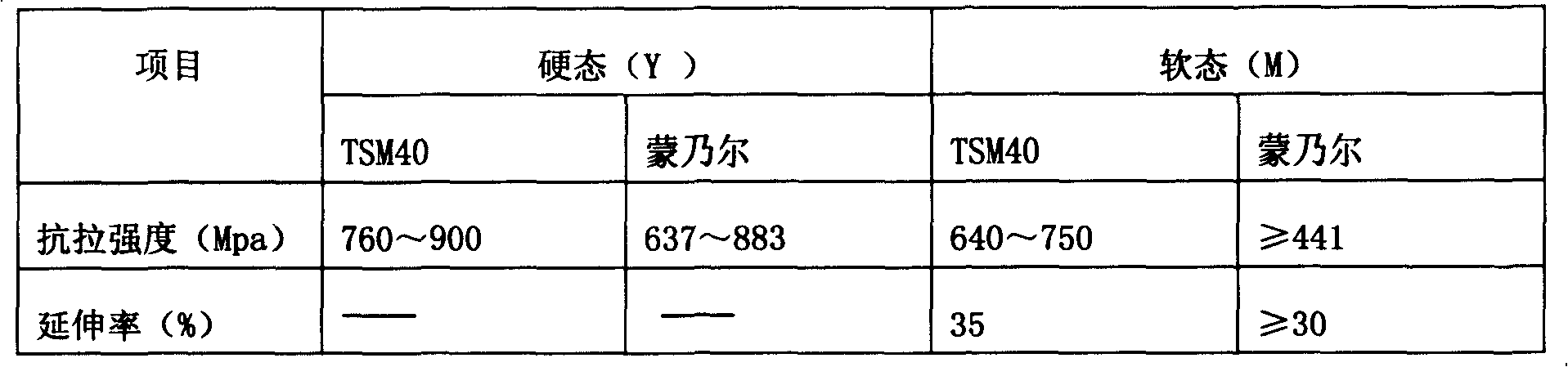

[0033] Table 2 Example 2-10 φ4.1mm product components and performance parameters

[0034]

[0035] It can be seen from the above table that compared with the existing material Monel, the performance of the product of the present invention is equivalent to it, but the cost is greatly reduced because the content of nickel in the components is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com