Simple carbon fiber composite circular rod body joint

A composite material and carbon fiber technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of high comprehensive cost of supporting hardware products, unfavorable promotion and use of carbon fiber products, low consistency and uniformity, and achieve excellent tensile strength Tensile strength and elongation, extensive detachability, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

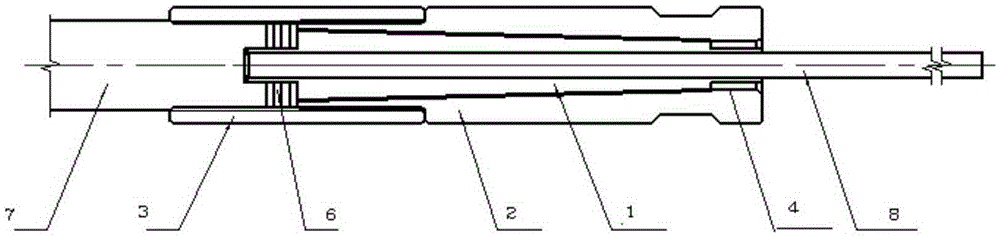

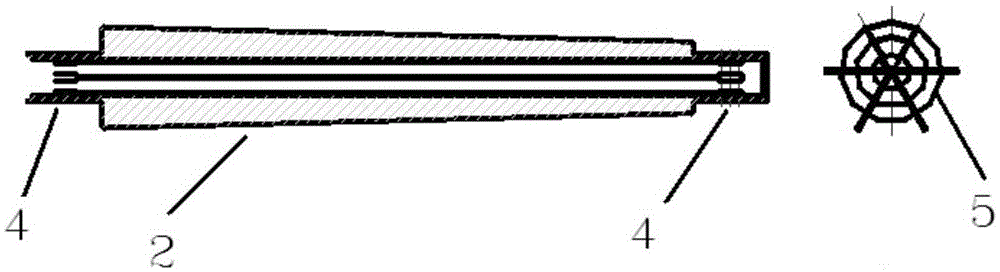

[0032] A simple carbon fiber composite material circular rod joint, the joint includes an inner cone 1, an outer cone 2, a sleeve 3, and a spring, and the outer wall of the inner cone 1 is wedged with the inner wall of the outer cone 2, The tail of the outer cone 2 is installed in the sleeve 3, the tail of the outer cone 2 is provided with a spring, and the head of the outer cone 2 is an inner cone structure; The rod 7 is set in the sleeve 3; when the joint is installed and the pulling force or pushing force on the carbon fiber mandrel 8 is less than 1600N, the carbon fiber mandrel 8 and the inner cone 1 are relatively stationary.

[0033] Compared with the existing fittings, the inner cone 1 and the outer cone 2 in the present invention are shorter in length, less difficult to process, and the cone surfaces fit well. Sleeve internal thread connection. The protective ring 4 and the multi-lobe structure 5 can be tightly combined with the composite material and reduce stress co...

Embodiment 2

[0035] The difference from Embodiment 1 is that the carbon fiber mandrel passes through a spring and engages with one end of the anchor rod. The carbon fiber mandrel is engaged by the card slot provided at one end of the anchor rod, which can further improve the stability of the connection. At the same time, the carbon fiber mandrel can realize the effective positioning of the spring and improve the bonding force between the parts of the joint. It is embedded at a depth of about 2-3mm, mainly for positioning. The carbon fiber mandrel can be moved from right to left, and then adjusted to insert the carbon fiber mandrel into the anchor rod, which is a solid structure.

Embodiment 3

[0037] The difference from Embodiment 1 is that the inner diameter of the spring is equal to the inner diameter of the tail of the inner cone. Ensure that the inner cone is evenly stressed, improve the tightness of the combination of the inner cone and the outer cone, and avoid the problem of uneven force on parts of the carbon fiber mandrel and easy breakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com