Instrument and process for regulating roller system of vertical wheel rolling mill

A technology for adjusting instruments and wheel rolling mills, which is applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., and can solve the problem of not being able to get rid of adjustments based on experience and feeling, unable to directly reflect the adjustment status of the rolling mill, and the position of each roll. Problems such as pre-setting, to achieve the effect of improving the accuracy of adjustment, saving raw materials, and shortening the adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

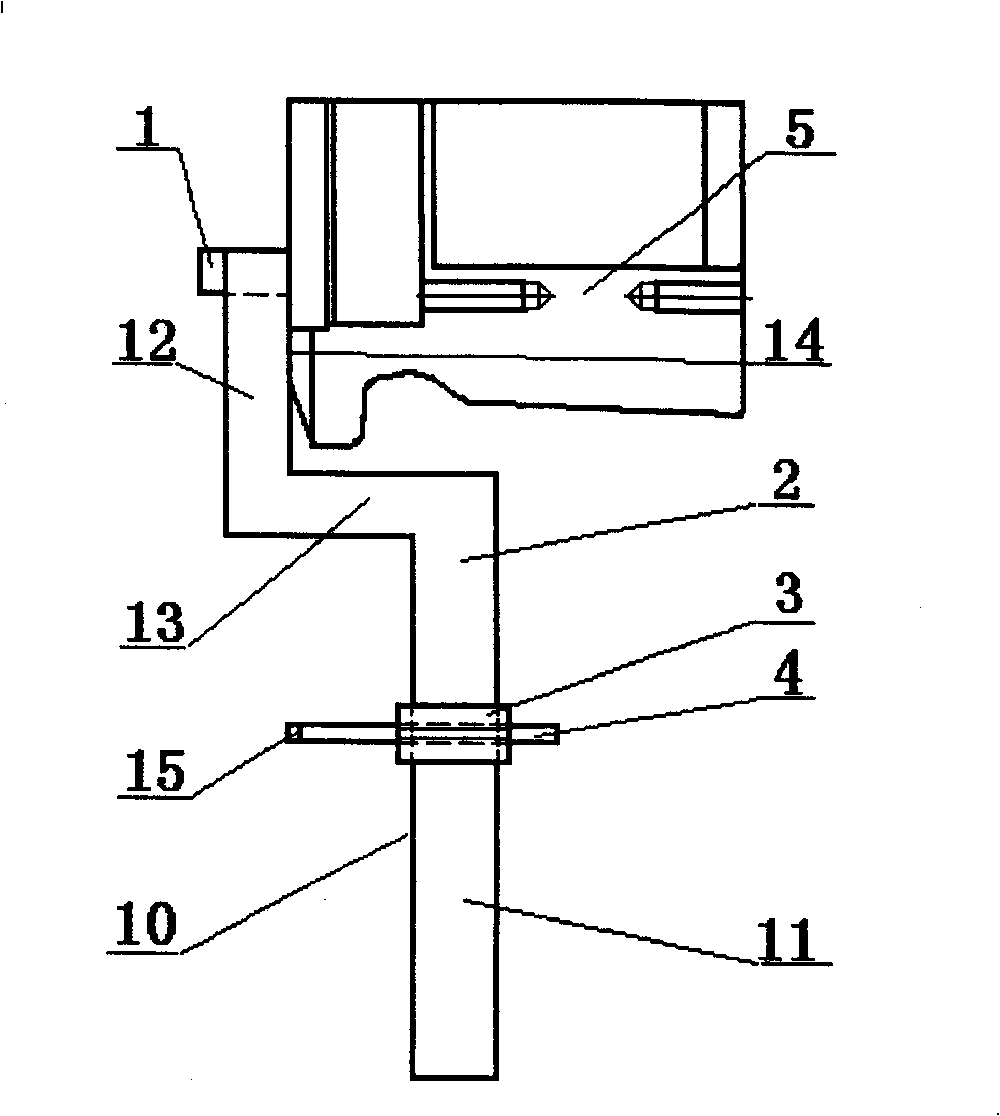

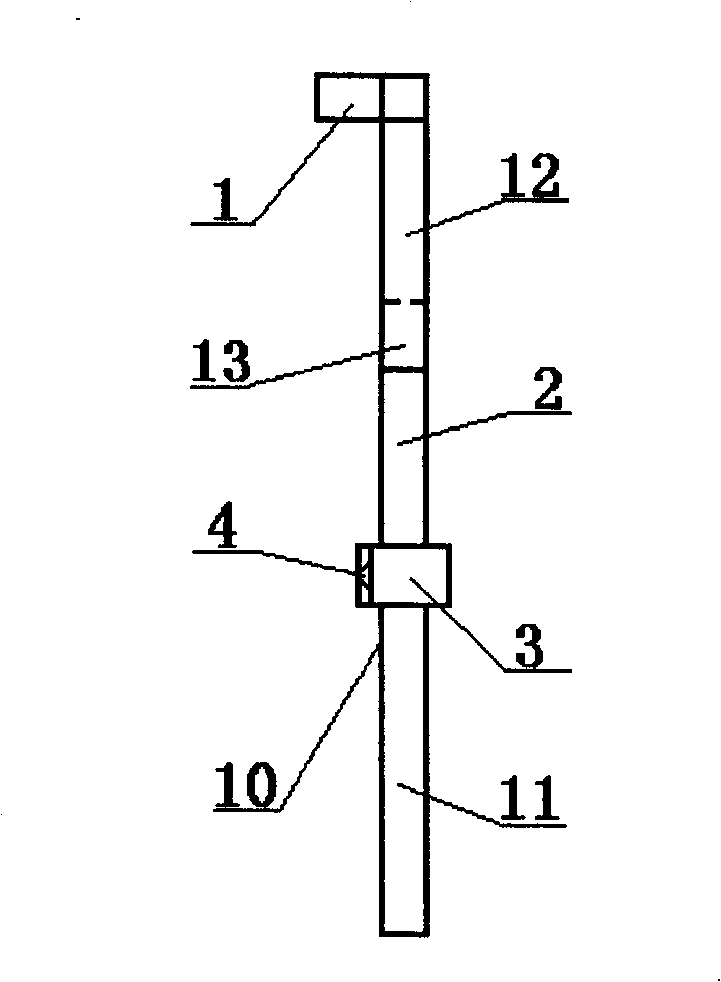

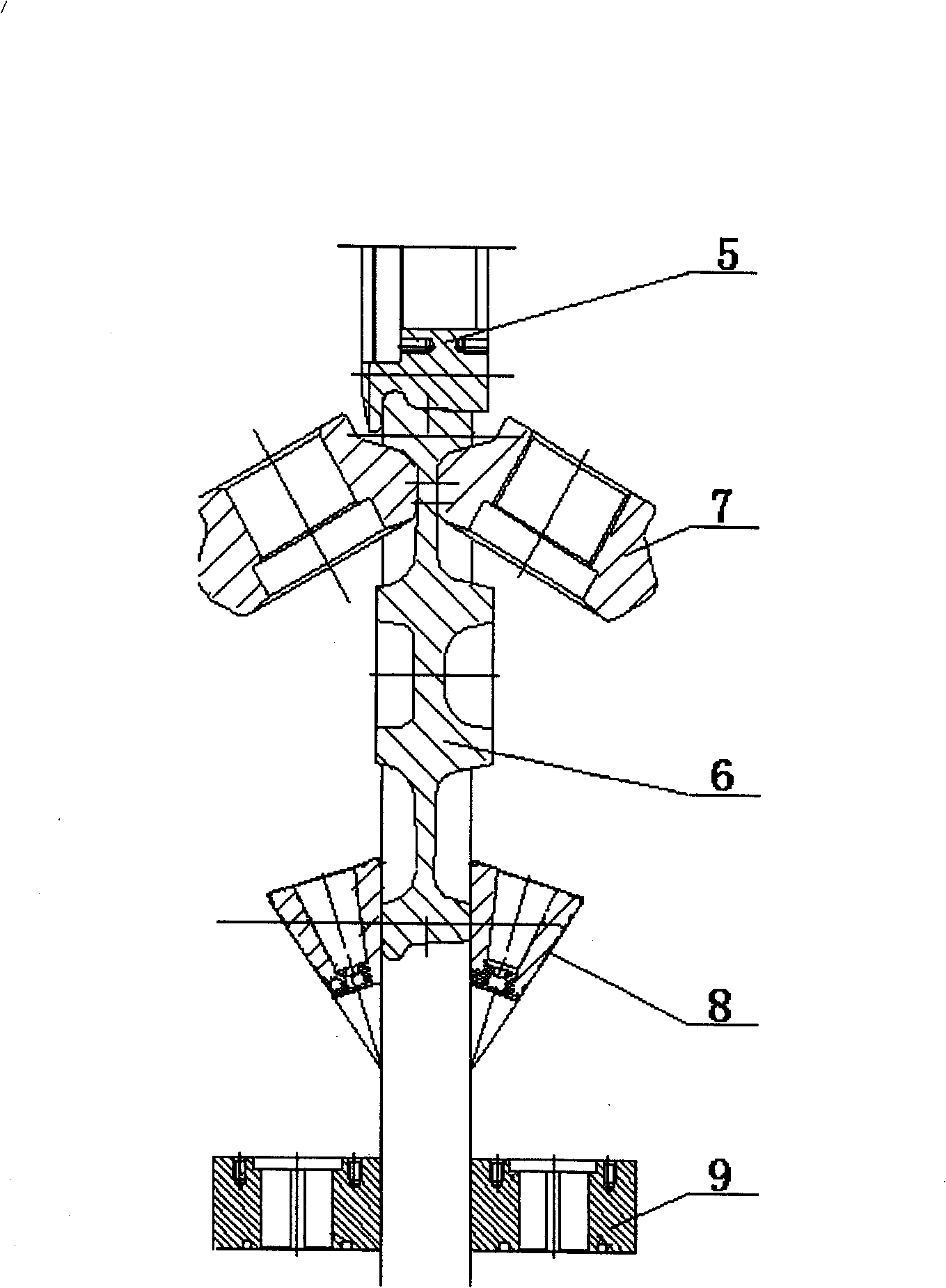

[0027] Such as Figure 1 to Figure 3 The structure of the present invention is expressed, and the present invention is a roll train adjustment instrument for a vertical wheel rolling mill. The roll system of vertical wheel rolling mill comprises main roll 5, spoke plate roll 7, skew roll 8 and guide roll 9, and main roll 5 rolls the excircle of wheel billet 6 rim, and its axis is parallel with the axis of wheel billet 6. A pair of symmetrically arranged web rollers 7 roll the inner circle and the web of the wheel billet 6 rim, and balance the rolling force with the main roll 5 in the radial direction of the wheel billet 6 . A pair of symmetrically arranged skewed rolls 8 roll the two end faces of the wheel billet 6 rims at the opposite wheel rims of the above-mentioned three rolls. The axes of web roller 7 and skew roller 8 form an included angle less than 90° with the axis of wheel steel billet 6, and the purpose is to make the roller shaft have the position of setting. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com