Carbon brush protector

A carbon brush and leaf spring technology, applied in the field of carbon brush holding devices, can solve problems such as small spring pressure and wear length, and achieve the effects of small installation depth, low manufacturing cost and large wear distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

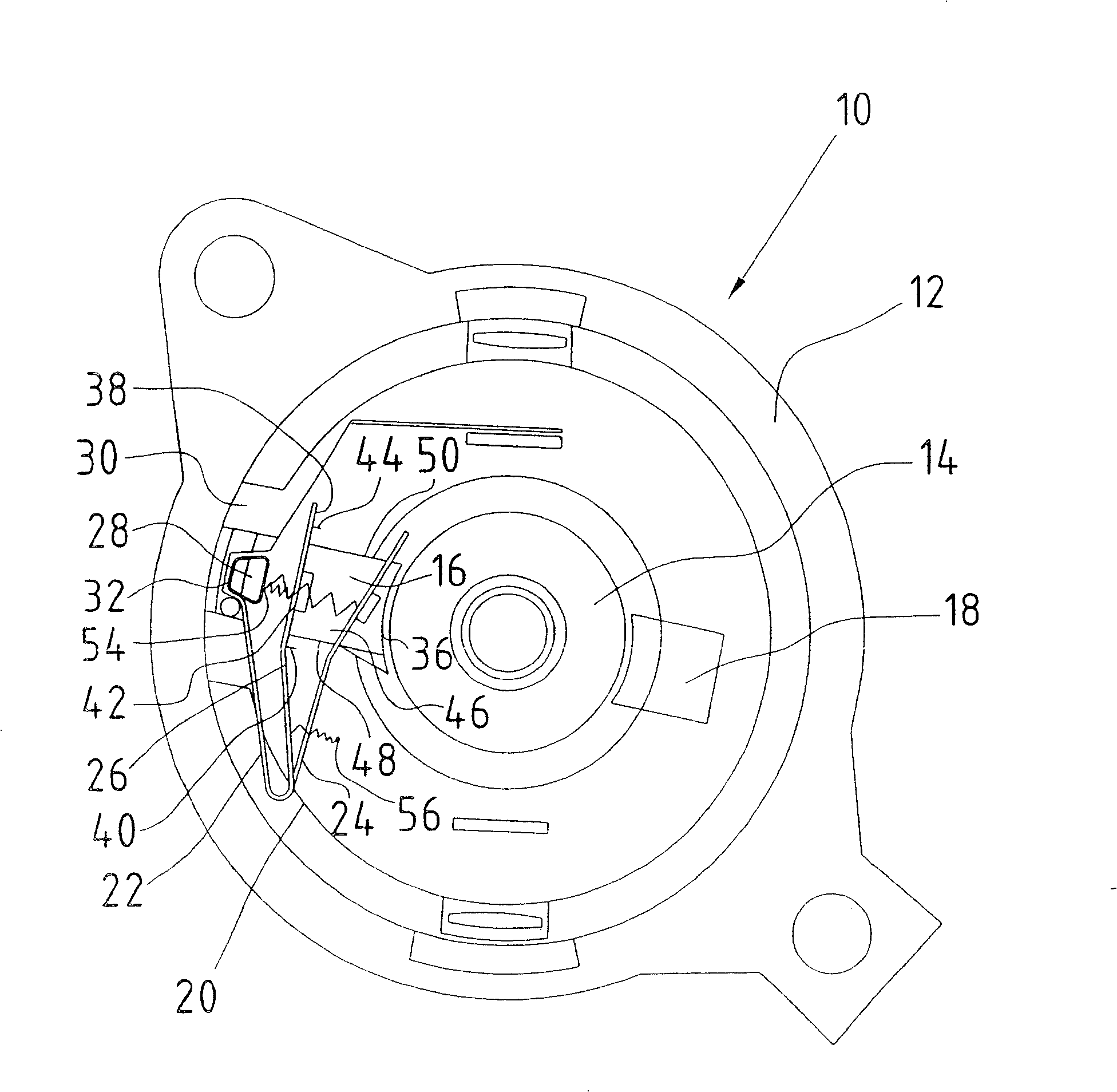

[0029] figure 1 A schematic diagram of a universal electric machine 10 is shown, which is intended, for example, for machine tools or domestic appliances, which are operated, for example, with a power of up to 2000 watts or 2500 watts.

[0030] The universal electric machine 10 comprises a housing 12 and an electric machine accommodated in this housing with a commutator 14 , against which carbon brushes 16 , 18 abut under force in order to transmit current. For this purpose, the carbon brushes 16 , 18 each protrude from a holding device (carbon brush holder) which is purely indicated in combination with the carbon brush 16 and is in the form of a known leaf spring 20 (carbon brush holder), which includes a holding leg Or holding part 22 and a carrier part 24 for receiving carbon brush 16 . The retaining portion 22 can be fixed between the support and the opposing support 26, 28, 30 in a known manner. For this reason, holding part 22 has in this embodiment a cross-section tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com