Intensified component, connector with the component, connection mechanism of electric component and substrate

A technology for connectors and components, applied in the field of reinforcing components, can solve the problems of reduced effective installation area, poor connection, and torsional stress imposed by connectors, and achieves the effects of improved bonding strength, improved bearing capacity, and enlarged bonding area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, embodiments of the reinforcing member and the connector equipped with the reinforcing member of the present invention will be described with reference to the drawings. However, the present invention is not limited to this. In addition, in the following description, the same reference numerals are attached to the same components, and the description is omitted or abbreviated. In addition, the directional terms such as front, back, left, right, up, down, etc. used in the following embodiments are used only for convenience of description.

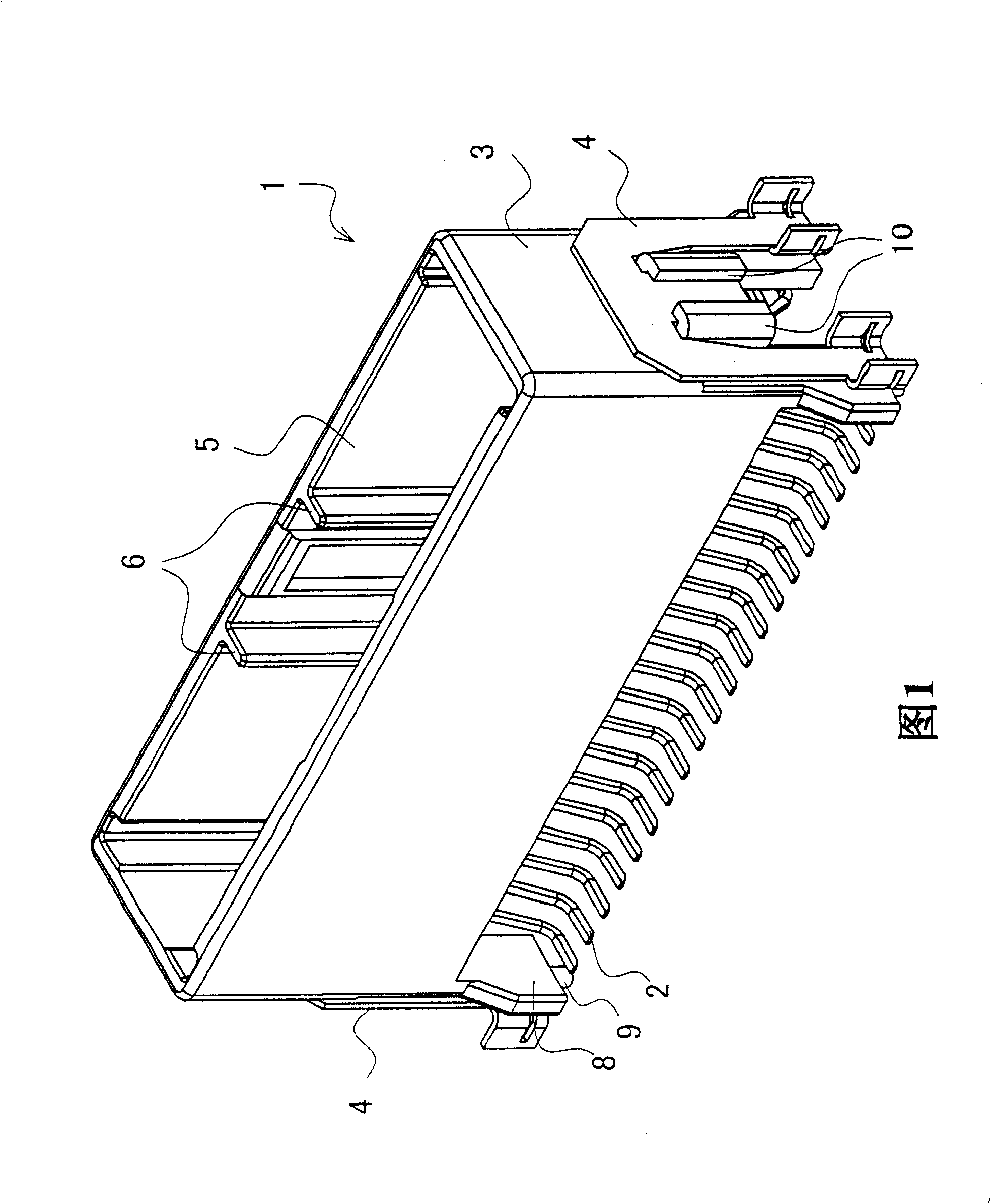

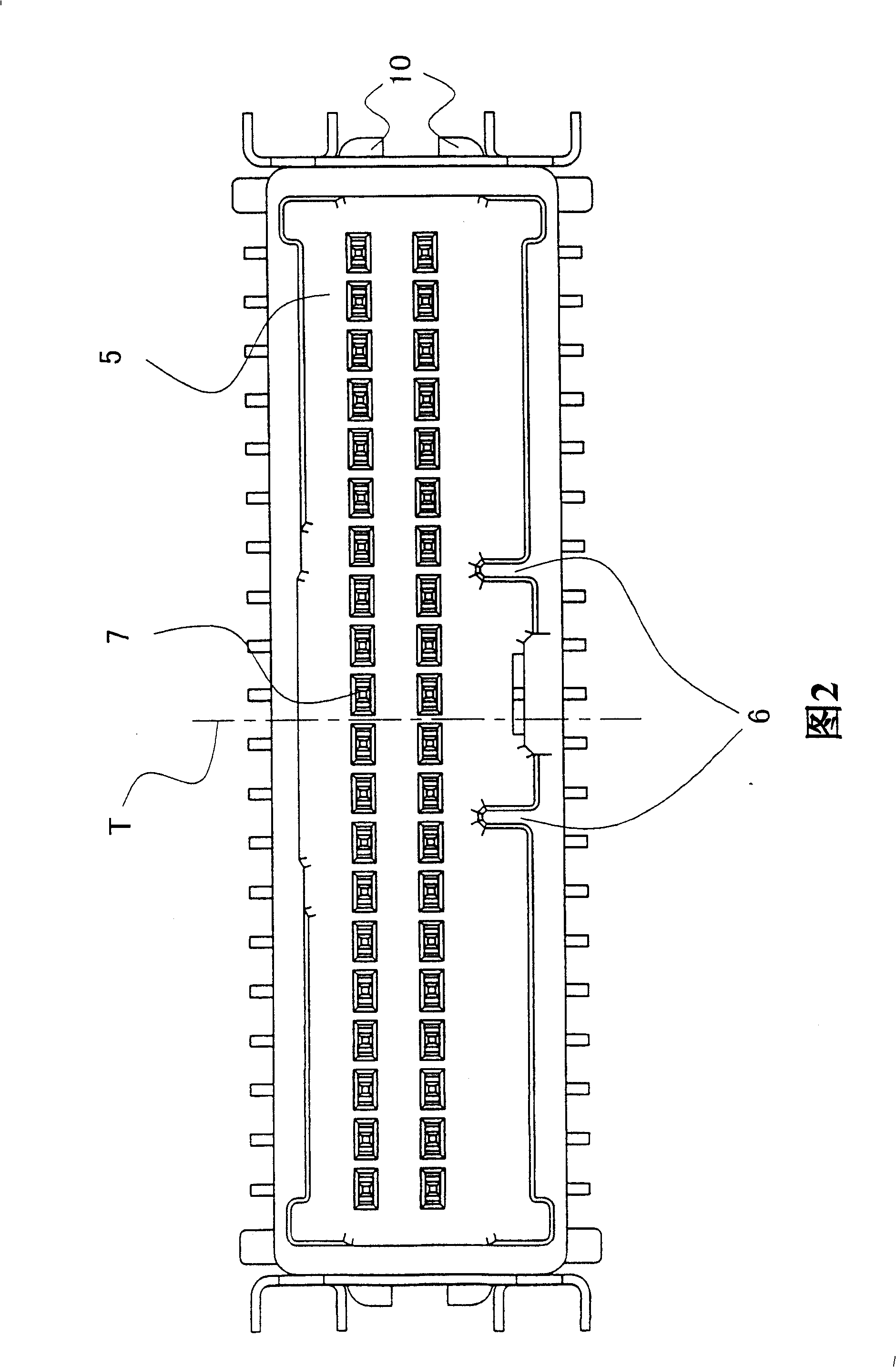

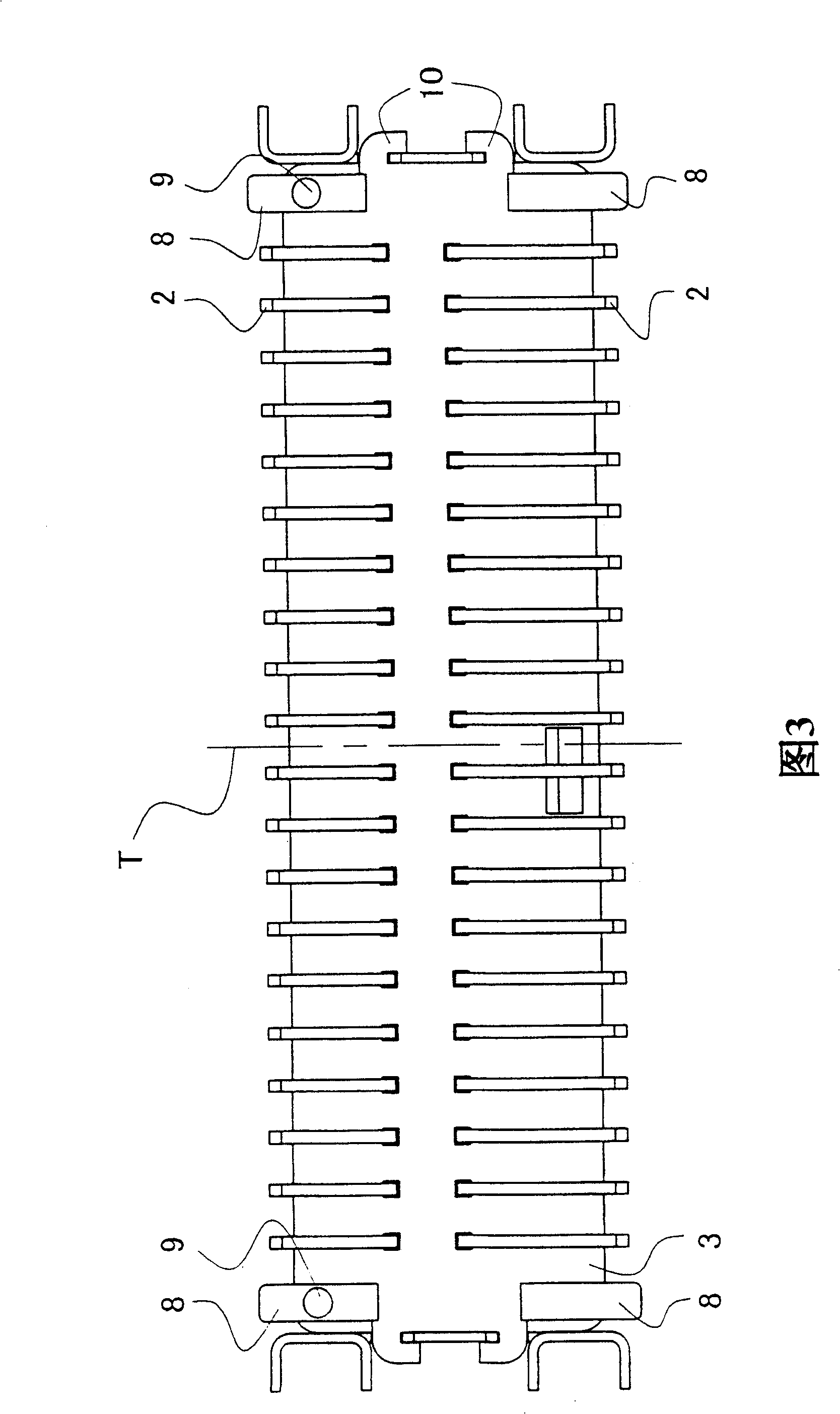

[0053] Fig. 1 is a perspective view of a connector provided with a reinforcing member of the present invention. Fig. 2 is a plan view of the connector. Figure 3 is a bottom view of the connector. Fig. 4 is a front view of the connector. Figure 5 It is a side view of the connector.

[0054] The connector 1 has an integrally molded housing 3 made of insulating resin, and the housing 3 is provided with a plurality of metal pin co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap