H-type shape steel vertical rolling method and apparatus

An H-beam, vertical technology, applied in the driving device of metal rolling mill, metal rolling, metal rolling, etc., can solve the problem of deterioration of mechanical properties of steel, increase of rolling force and rolling torque, and rolling production capacity. It can reduce energy consumption and other consumption, reduce rolling force and torque, and slow down temperature drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

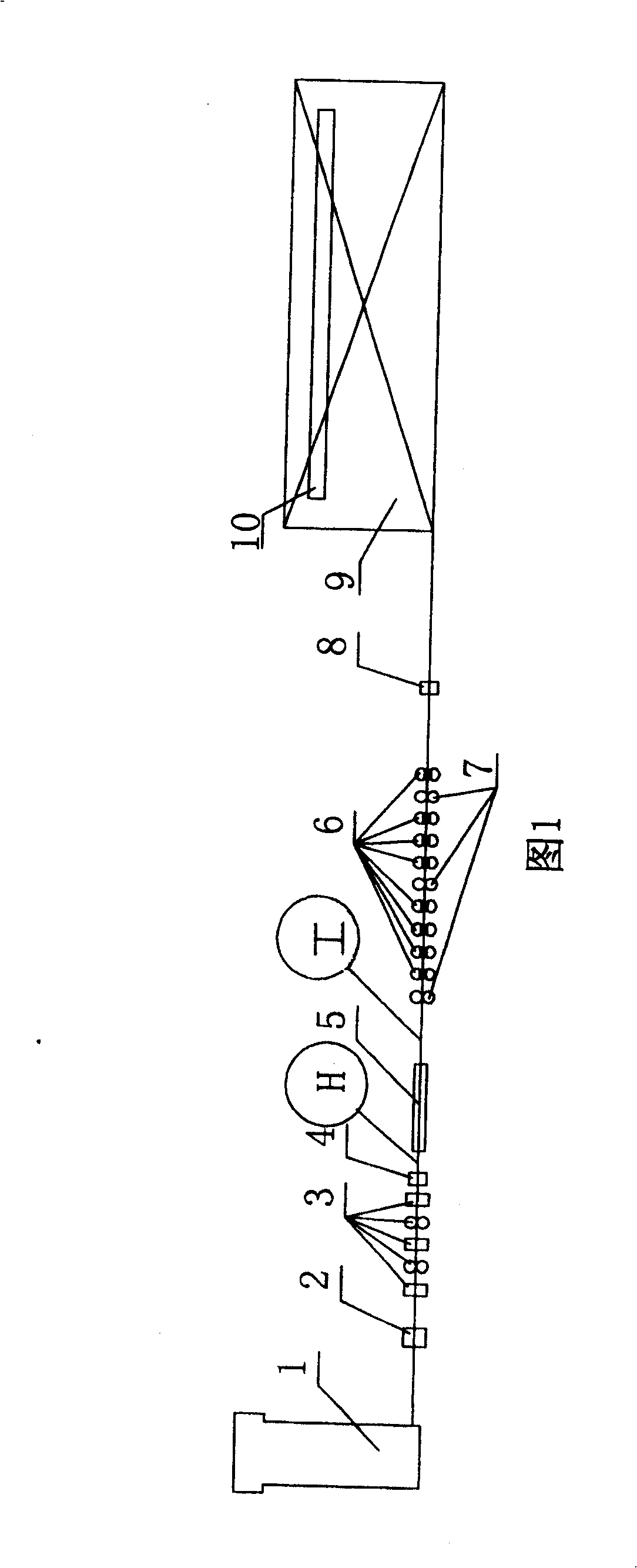

[0018] It can be seen from Figure 1 that the steel billet is heated by the heating furnace 1, descaled by the high-pressure water descaling machine 2, rolled by the billet rolling mill 3, and cut by the head cutting device 4. The rolled piece is in the shape of "H" and the web is horizontal In the vertical state, the flange is in a vertical state, sent to the turning device 5, the rolled piece is turned 90 degrees, and the web of the rolled piece enters the vertical universal rolling mill 6 and the vertical edger 7 in a vertical state for several passes of intermediate and finish rolling. . In the middle and finish rolling process, the web of the rolled piece is in a vertical state, and the flange is in a horizontal state. After rolling and forming, it is cut by the cutting device 8 and sent to the cooling bed 9. The finished product turning device installed on the cooling bed 9 10. Turn over the finished "H" shaped steel by 90 degrees to facilitate cooling on the cooling bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com