Sliding closing element, with coupling

A technology for closing elements and couplings, applied in the direction of connecting components, manufacturing tools, threaded fasteners, etc., can solve problems such as affecting the sliding closing function, control errors, and cumbersome couplings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

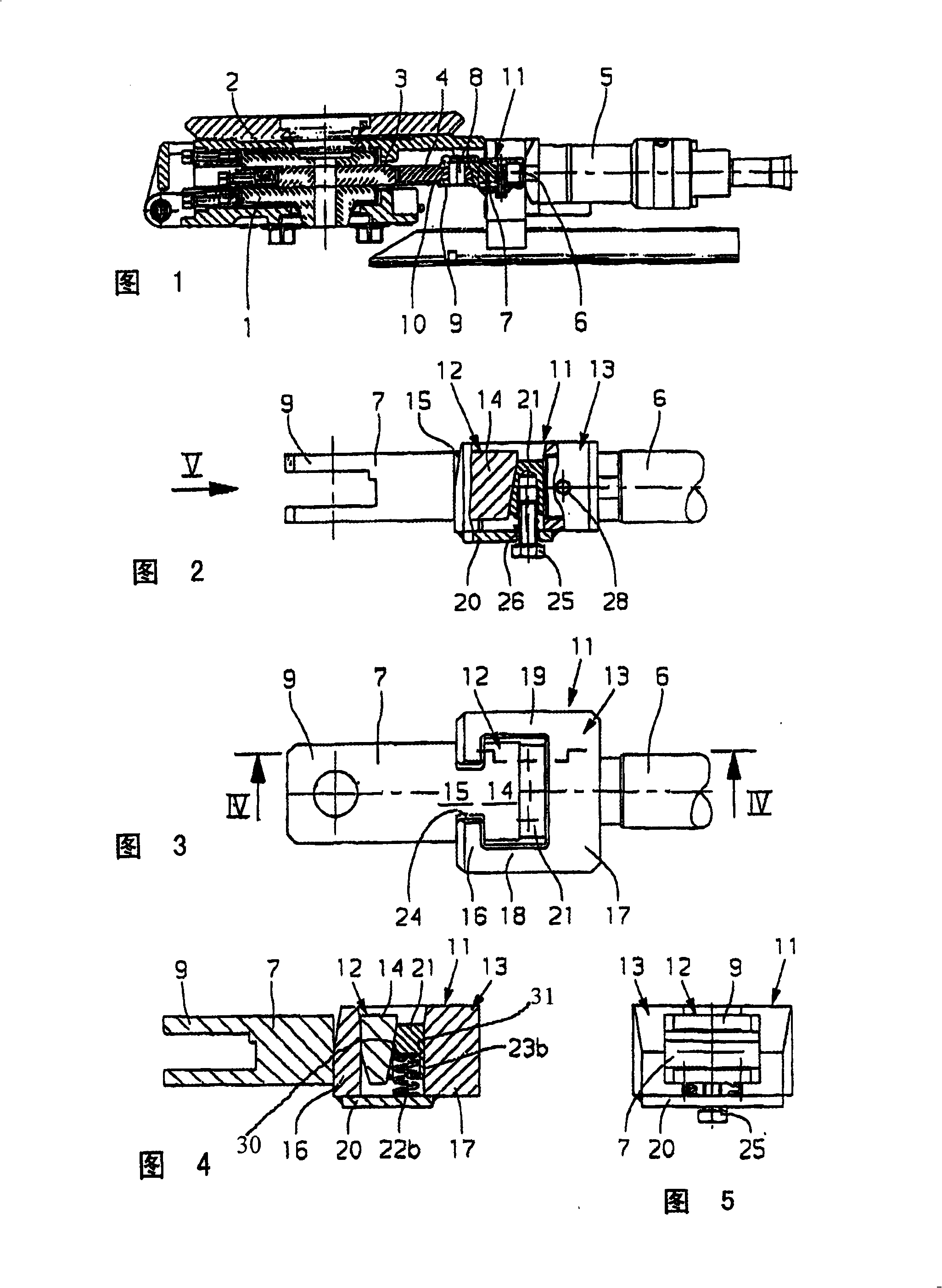

[0029] The sliding closing element shown in Fig. 1 comprises two partially fixed sliding plates 1, 2 on an intermediate distributor (not shown in detail) and a movable sliding plate 3 placed between these two sliding plates, the movable sliding plate being located between the sliding plates Frame 4 is tensioned inside. The slide frame can be driven by a hydraulic cylinder 5, the drive rod 6 of the hydraulic cylinder is connected with a push rod 7, and the push rod 7 is attached to the slide frame 4 together with the movable slide 3. The push rod 7 is fitted with a bolt 8 protruding through the fork-shaped head 9 of the push rod 7 and inserted into the shoulder 10 of the skateboard frame 4 in the fork-shaped head 9 .

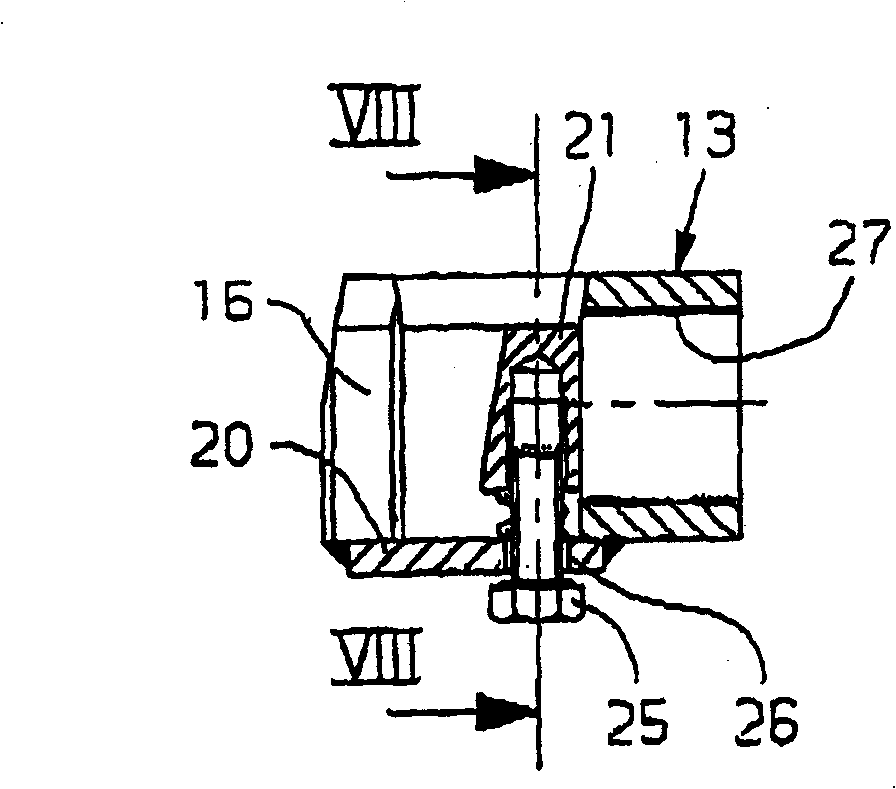

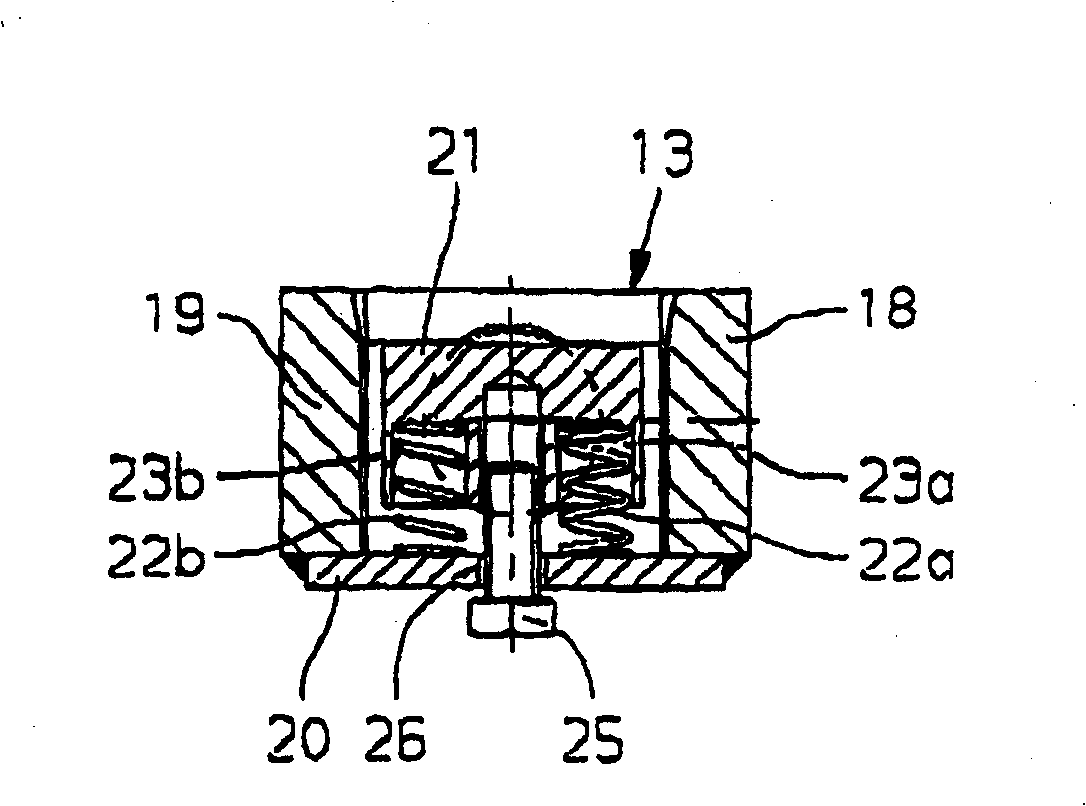

[0030] The coupling between the drive rod 6 and the push rod 7 is produced by means of a coupling 11 which is equipped with a coupling head 12 and a coupling dog 13 which is positively and non-positively received by the coupling head.

[0031] The coupling head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com