Full- fusing wind-cooling crystallization granulation method and device for composite fertilizer

A technology of granulating device and compound fertilizer, which is applied to fertilizing device, fertilizer form, fertilizer mixture, etc., can solve the problems such as difficulty in adjusting the ratio of sticky dust and products, poor granulation effect, etc., so as to save investment cost and reduce Energy consumption, the effect of a large scale range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following structural drawings and embodiments further illustrate the present invention.

[0026] A kind of air-cooled crystallization granulation method of full melting compound fertilizer, it specifically comprises the following steps:

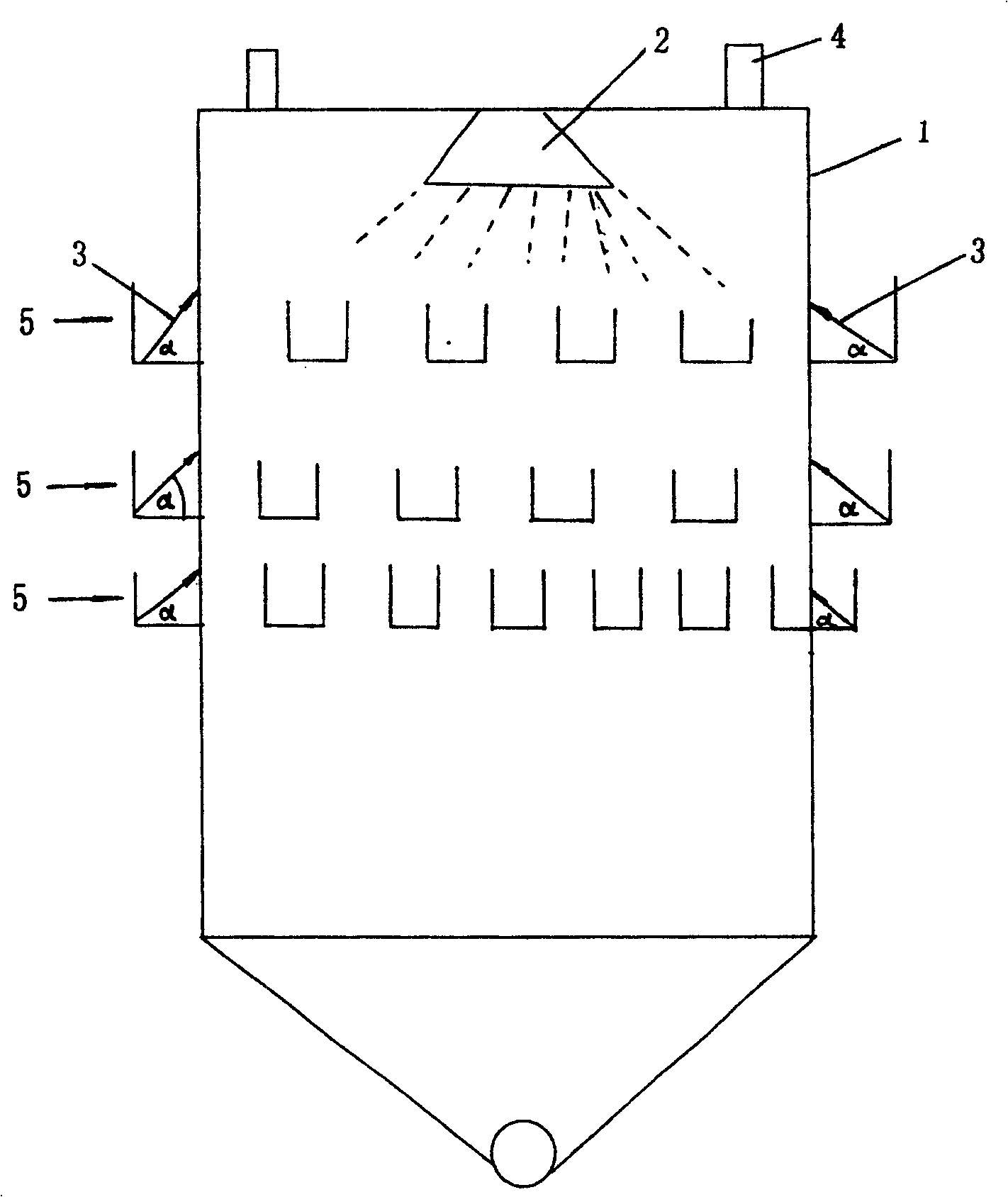

[0027] In the first step, the compound fertilizer slurry in the fully molten state is sprayed from the rotary granulation head located at the top of the prilling tower with a tower height of 15-50 meters and a tower diameter of 6-12 meters;

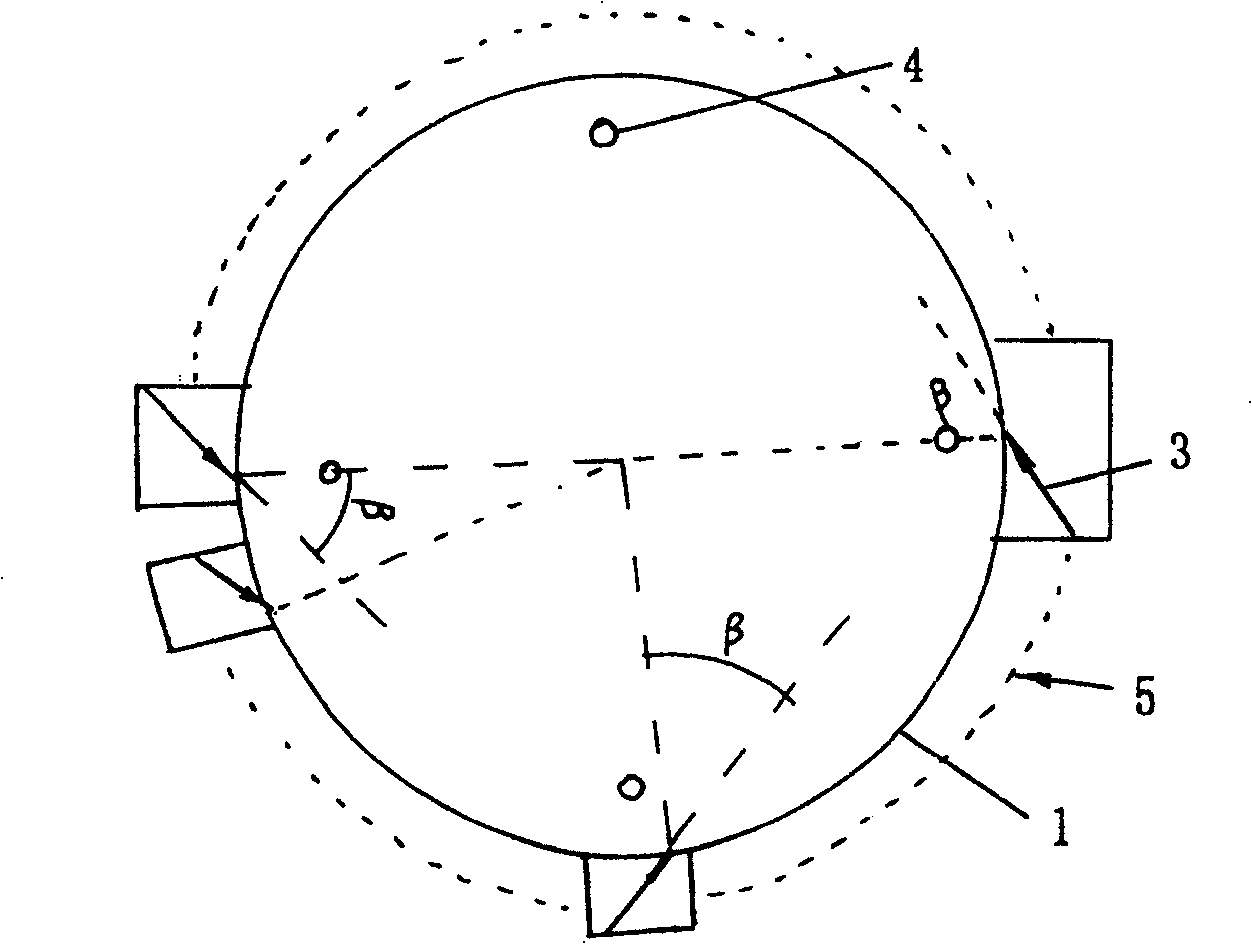

[0028] The second step is to install the first group of cooling fans blowing into the tower around the prilling tower body at a position of less than 4 meters (including 4 meters) from the prilling head, so that the air outlet direction of each fan is in line with the horizontal plane. The included angle is 0-75 degrees, the best is 15-60 degrees, and the direction between the diameter and the diameter is 0-75 degrees (the best is 5-45 degrees) to deliver cooling air to the tower, and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com