Valve nozzle

A nozzle and valve technology, applied in the field of valve nozzles and closed nozzles, can solve the problems of narrow temperature range, poor resin thermal balance, easy adhesion of flow marks to molded products, etc., to achieve smooth resin flow, improved maintainability, and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

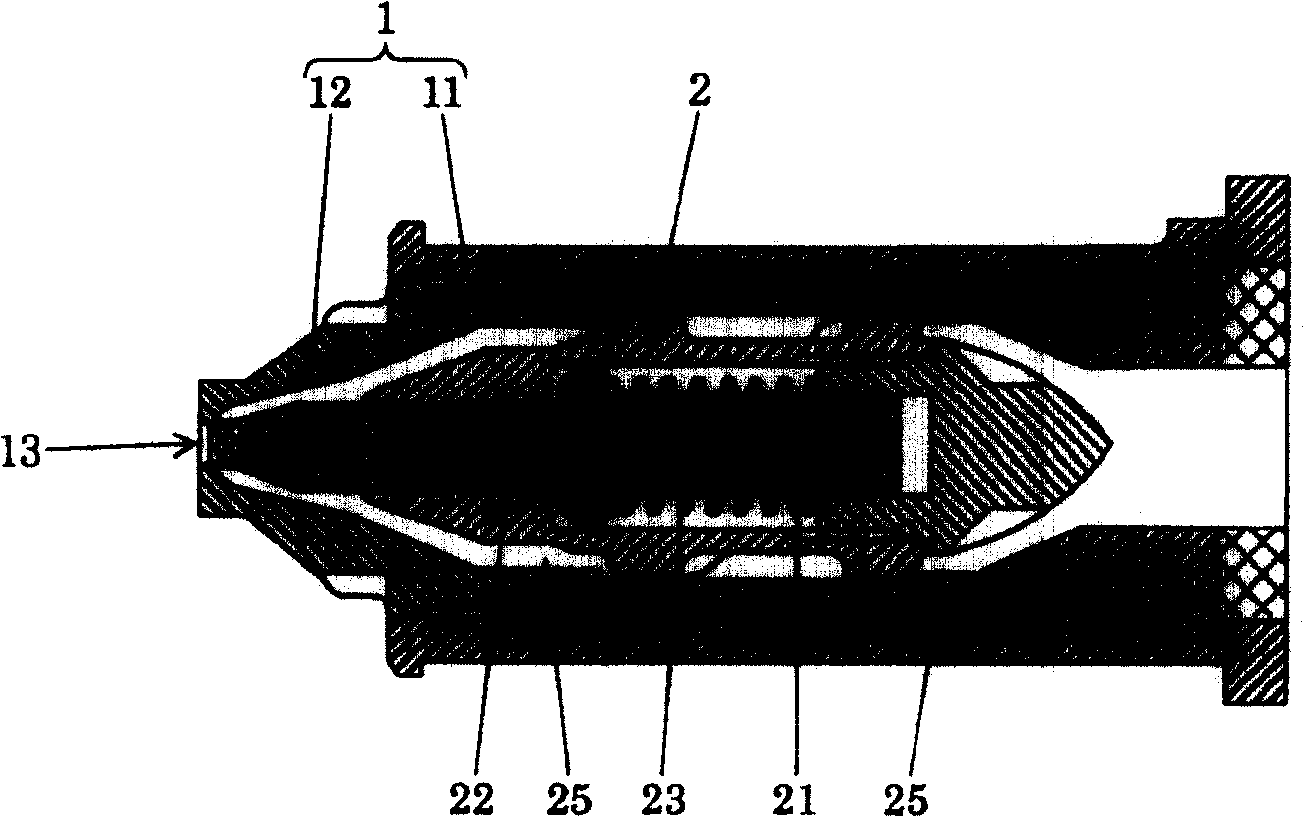

[0028] figure 1 Among them, the valve nozzle of the embodiment shown in the present invention is mainly composed of a valve nozzle body 1 and a gate opening and closing mechanism 2 arranged in the inner space of the valve nozzle body 1 .

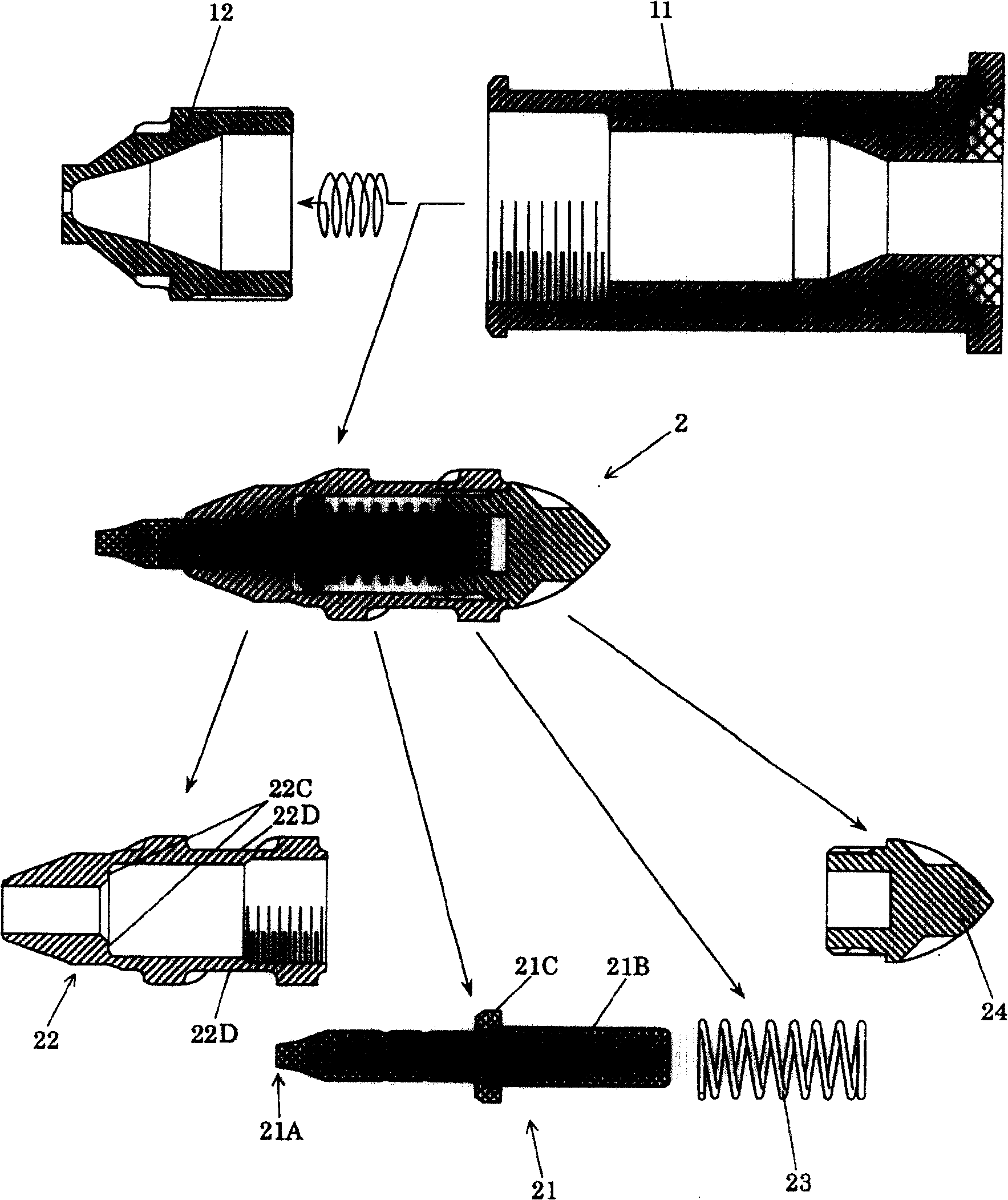

[0029] Valve nozzle body 1 such as figure 2 As shown, there are a nozzle base 11 and a nozzle tip 12 screwed to the nozzle base 11, and a gate 13 is formed at the front end of the nozzle tip.

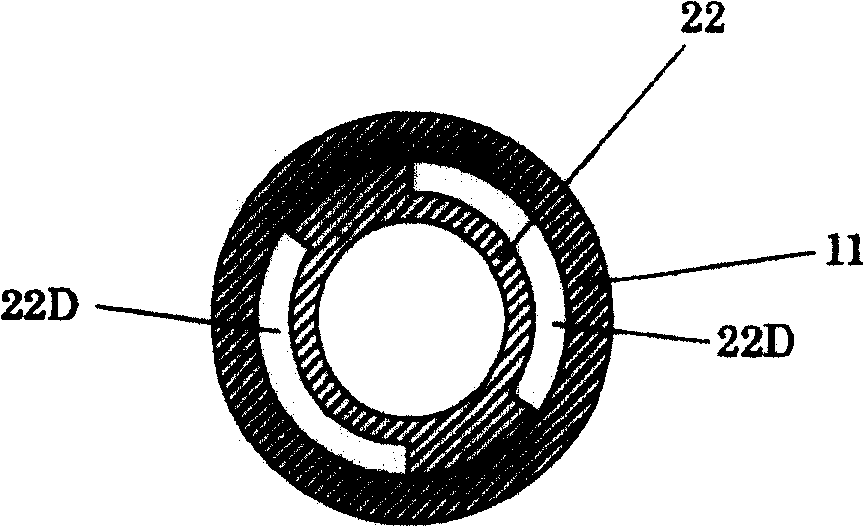

[0030] Gate opening and closing mechanism 2 such as figure 2 As shown, it is composed of a piston 21, a torpedo-shaped part 22, a coil spring 23 and a cover 24, which are assembled into one body and arranged in the inner space of the valve nozzle body 1. The piston 21 has a head portion 21A and a shaft portion 21B formed continuously from the head portion 21A. The torpedo-like member 22 slidably supports the piston 21, guides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com