Micro-mechanical reciprocating membrane pump

A diaphragm pump and micro-mechanical technology, applied in mechanical equipment, liquid variable capacity machinery, pumps, etc., can solve the problems of uncertain dead time, large amount of fluid occupied, no inertial rectification, etc., and achieve consistent and reduced dwell time. Output pulsation and reduce the effect of occupying the volume of test solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

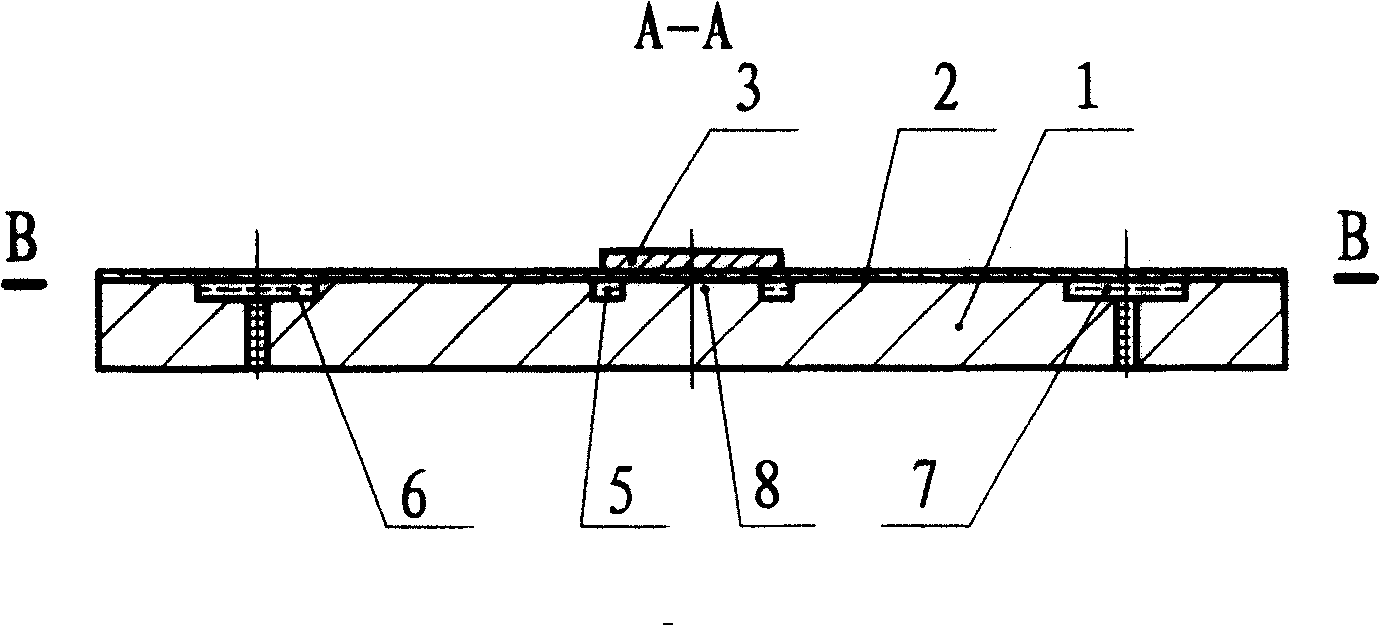

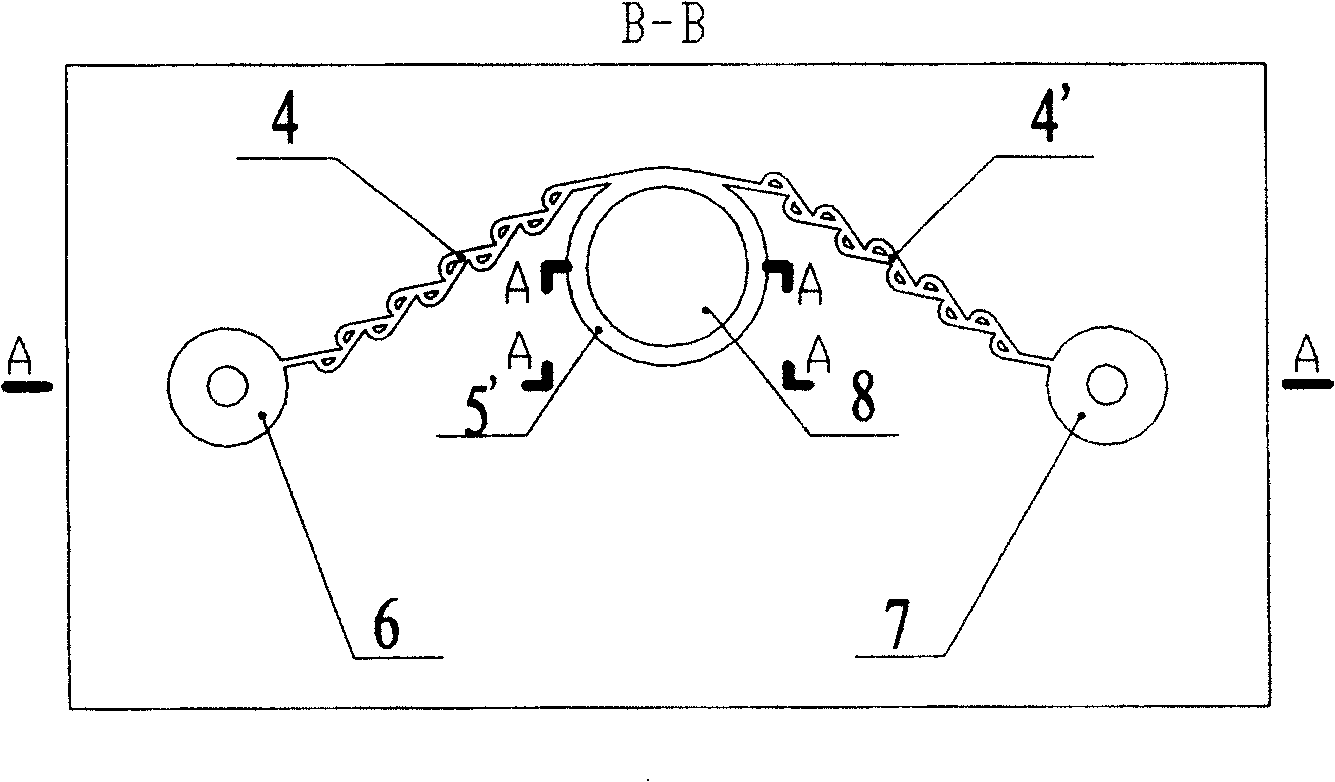

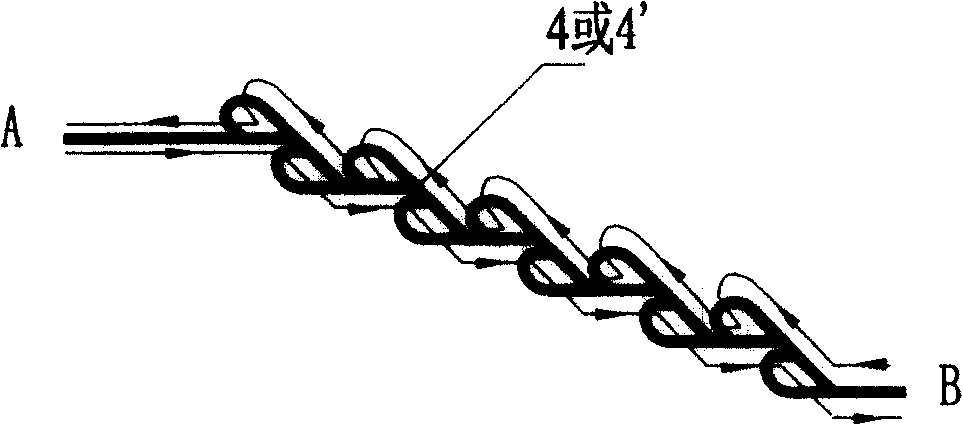

[0023] Such as figure 1 , figure 2 As shown, the micromechanical pump of the present invention is formed by bonding the pump body substrate 1 and the diaphragm 2 , and bonding the diaphragm 2 and the piezoelectric vibrator 3 . An annular groove 5' and a circular platform 8 are etched on the upper surface of the pump body substrate 1 in the port section, and an inertial annular cavity 5 is formed between the diaphragm 2; the inertial annular cavity 5 is connected to the input cavity through two inertial rectification channels 4, 4' 6. The output chamber 7 is connected. The port sections of the inertial rectification channels 4, 4' form a tangential positional relationship with the inertial annular cavity 5, and a port-to-portal positional relationship is formed between the ports of the two inertial rectification channels 4, 4'. In the inertial rectification channel 4 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com