Pumping well without energy consumption liquid injection pump

A technology that has no energy consumption and pumps oil wells. It is applied in the field of liquid injection pumps. It can solve the problems that the motor cannot reach the pump pressure, increase operating costs, and the energy consumption of liquid injection pumps is high. It achieves energy saving, small investment, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

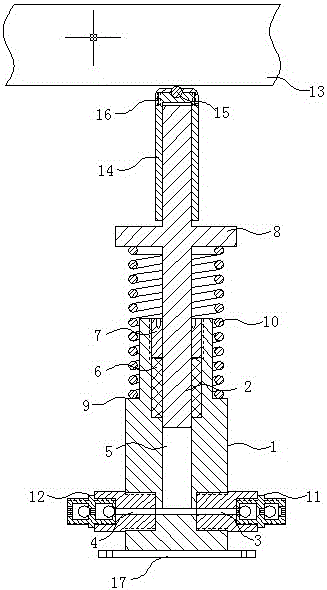

[0011] The non-energy-consuming liquid injection pump for pumping wells of the present invention is composed of a pump body 1, a plunger 2, a liquid inlet 3 and a liquid outlet 4. As shown in the figure, both sides of the lower part of the pump body 1 are symmetrically provided with liquid inlets. 3 and the liquid outlet 4, one end of the plunger 2 is placed in the inner chamber 5 of the pump body 1, the liquid inlet 3 and the liquid outlet 4 are connected with the inner chamber 5, and the upper part of the inner chamber 5 is provided with a packing 6 The gland 7 connected to the top of the pump body 1 by the screw port is fixed, and the upper part of the other end of the plunger 2 is fixed with a pressure plate 8. A spring 10 is arranged between the pressure plate 8 and the annular boss 9 on the upper part of the pump body 1. The upper screw port of the liquid inlet 3 is connected with the liquid inlet check valve body 11, the screw port of the liquid outlet 4 is connected wit...

Embodiment 2

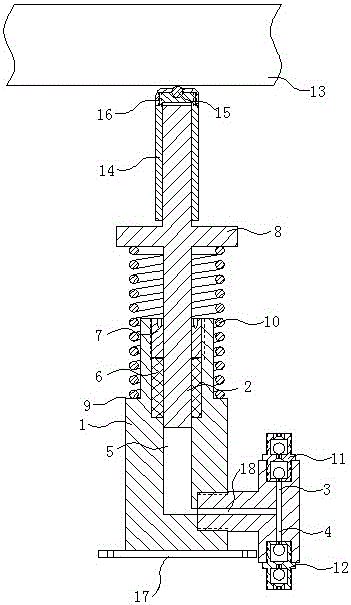

[0013] The energy-free liquid injection pump for pumping wells of the present invention is composed of a pump body 1, a plunger 2, a liquid inlet 3 and a liquid outlet 4, as figure 2 As shown, the bottom of the pump body 1 is provided with a pump base 17, and one side of the lower part of the pump body 1 is provided with a liquid inlet 3 and a liquid outlet 4, and one end of the plunger 2 is placed in the inner cavity 5 of the pump body 1 to enter The liquid port 3 and the liquid outlet 4 communicate with the inner cavity 5 of the pump body 1 through the communication hole 18 in the valve body; The inner wall of the top is fixed with a threaded buckle, the middle and upper part of the plunger 2 is fixed with a pressure plate 8, a spring 10 is provided between the pressure plate 8 and the annular boss 9 on the upper part of the pump body 1, and a protective sleeve 14 is provided on the upper part of the plunger 2. Be provided with bearing 15 at the top of protective cover body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com