Chip micro flow electroosmosis pump

An electroosmotic pump and chip technology, which is applied in the field of micro-infusion and low-pressure micro-flow infusion pumps, can solve the problems of difficult to accurately deliver the flow rate, and does not solve the problems of removing air bubbles and forming air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

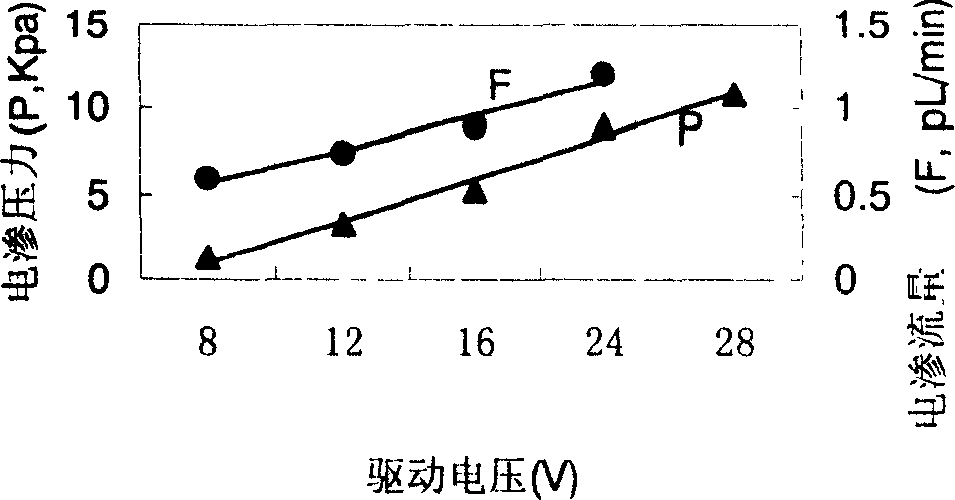

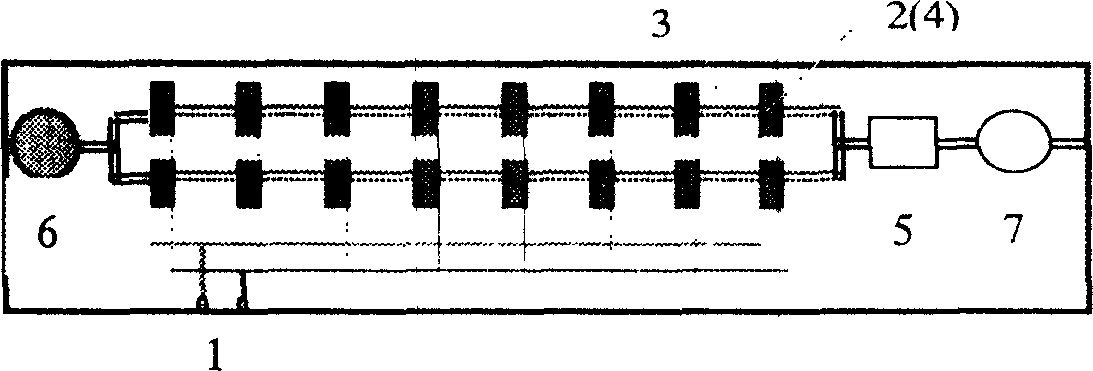

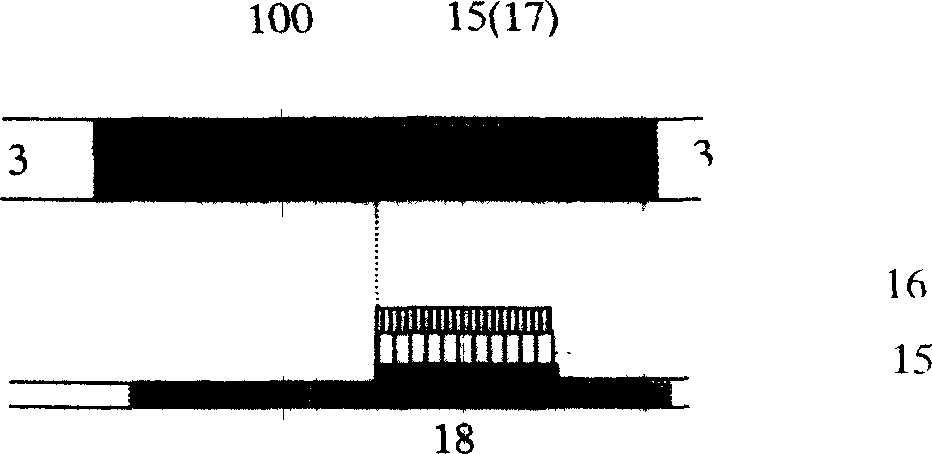

Embodiment 1

[0036] Example 1: Single-stage filling channel pump, copper plate electrode, using silica gel filler with a filling channel length of 2.0 cm, an equivalent inner diameter of 75 μm, and an inner particle size of 1 μm, an equivalent inner diameter of an etched microchannel of 10 μm, and an aqueous solution with a pH value of 7.0. Driving voltage 130-200V, flow range 0.1-0.4nL / min, output pressure 0.3-3kPa;

Embodiment 2

[0037] Embodiment 2: Two-stage filling channel pump, stainless steel plate electrode, using silica gel filler with a filling channel length of 2.0 cm, an equivalent inner diameter of 200 μm, and an inner particle size of 1 μm, and an etched microchannel with an equivalent inner diameter of 5 μm, and the remaining conditions are the same as in Example 1. Driving voltage 80-150V, flow range 0.3-2.5nL / min, output pressure 0.1-1.5KPa;

Embodiment 3

[0038] Example 3: Eight-segment filling channel pump, crossing gold plate electrode, using filling channel length 0.5cm, inner filling equivalent inner diameter 100 μm, particle size 1 μm inner molding filler, etching microchannel equivalent inner diameter 10 μm, driving voltage 30-50V, Flow range 0.2-0.5nL / min, output pressure 0.1-5KPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com