An in-line distribution type fully electronically controlled fuel injection pump assembly

An electronically controlled fuel injection and distribution technology, which is applied to fuel injection pumps, fuel injection devices, engine components, etc., can solve problems such as poor consistency of fuel volume, and achieve the advantages of eliminating fuel volume differences, convenient installation and maintenance, and improving control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

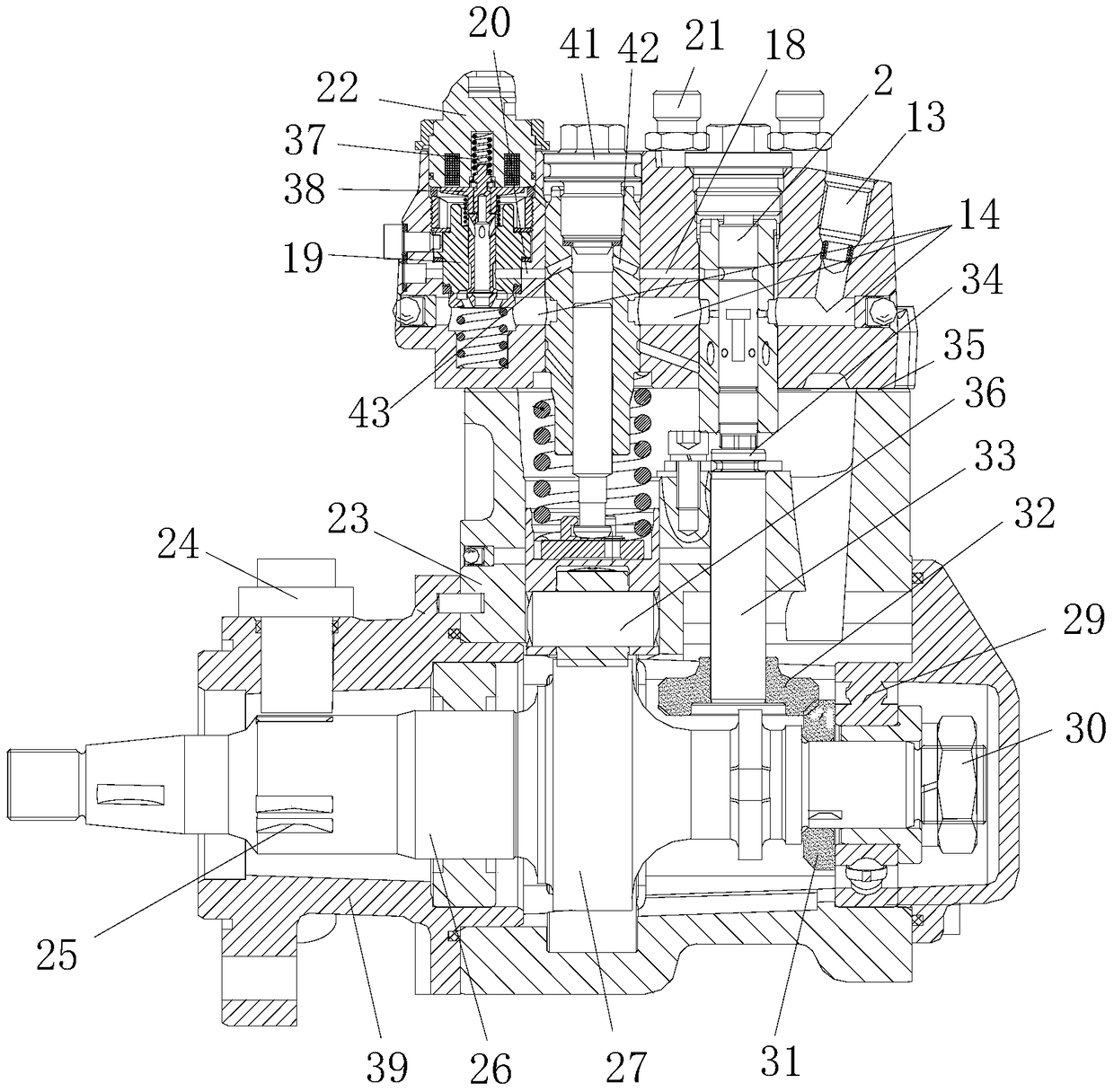

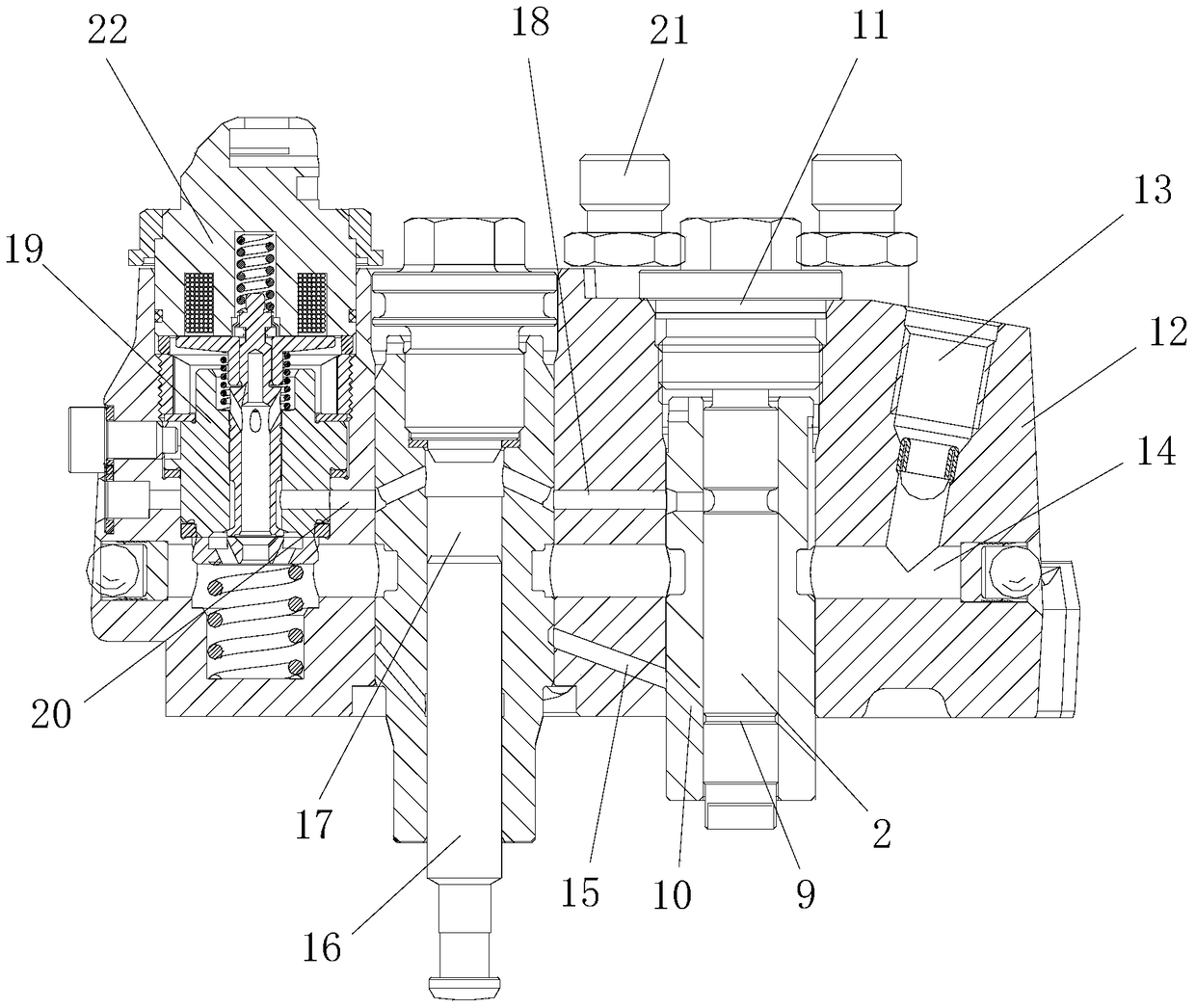

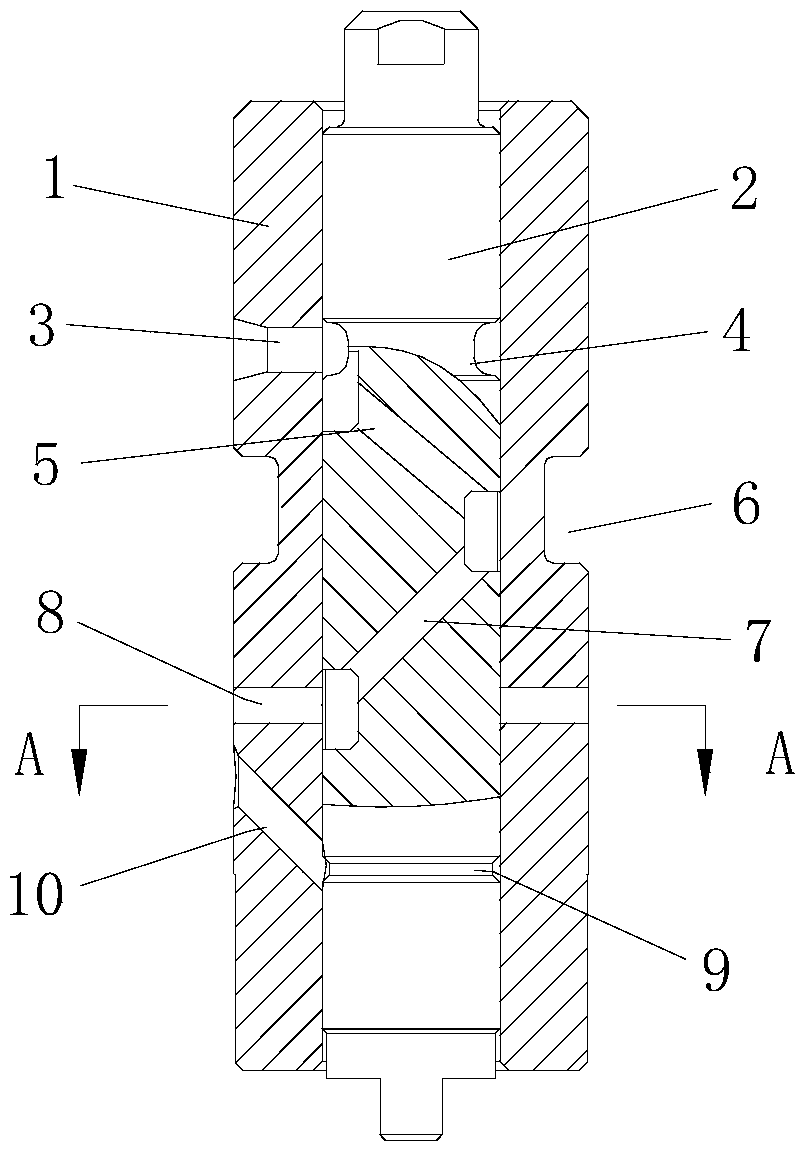

[0033] Such as Figure 1 to Figure 6As shown, an in-line distribution type fully electronically controlled fuel injection pump assembly includes a pump body 23 and a pump head 12, a gasket 35 is arranged between the pump body 23 and the pump head 12, and a low-pressure fuel inlet 13 is arranged on the pump head 12 and the low-pressure oil chamber 14, the low-pressure fuel inlet 13 is connected with the oil delivery pump arranged on the outside of the pump body 23, the front end of the pump body 23 is equipped with a transition flange 39, and the front end of the transition flange 39 is evenly distributed with eleven The positioning round hole used to realize the connection between the fuel injection pump assembly and the engine, the pump body 23 is provided with a camshaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com