Tail gas purification device based on electric heating for tunnel construction machinery

A technology of exhaust gas purification device and tunnel construction, which is applied in the direction of exhaust device, electronic control of exhaust gas treatment device, diagnosis device of exhaust gas treatment device, etc., can solve the problem of poor air circulation, insufficient combustion of construction machine engine, oxygen concentration low problems, to achieve the effect of reducing air pollution, reducing the generation of exhaust pollutants, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

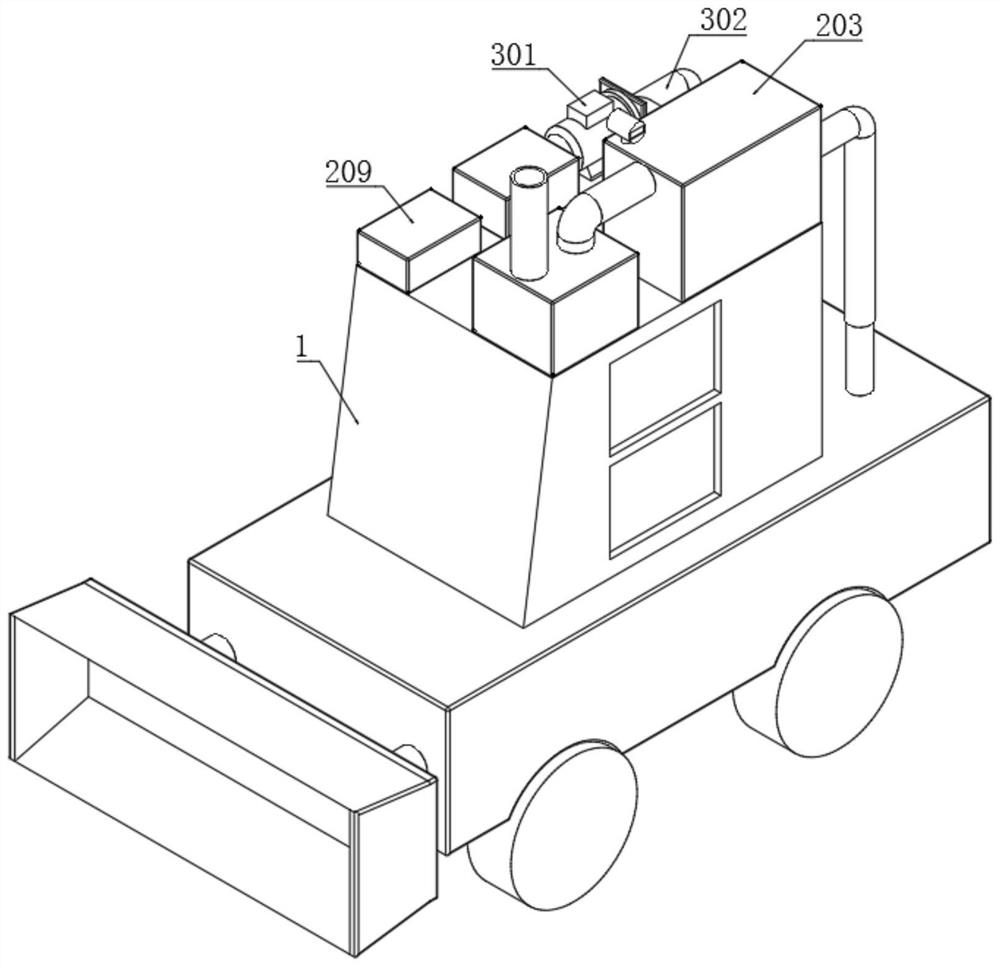

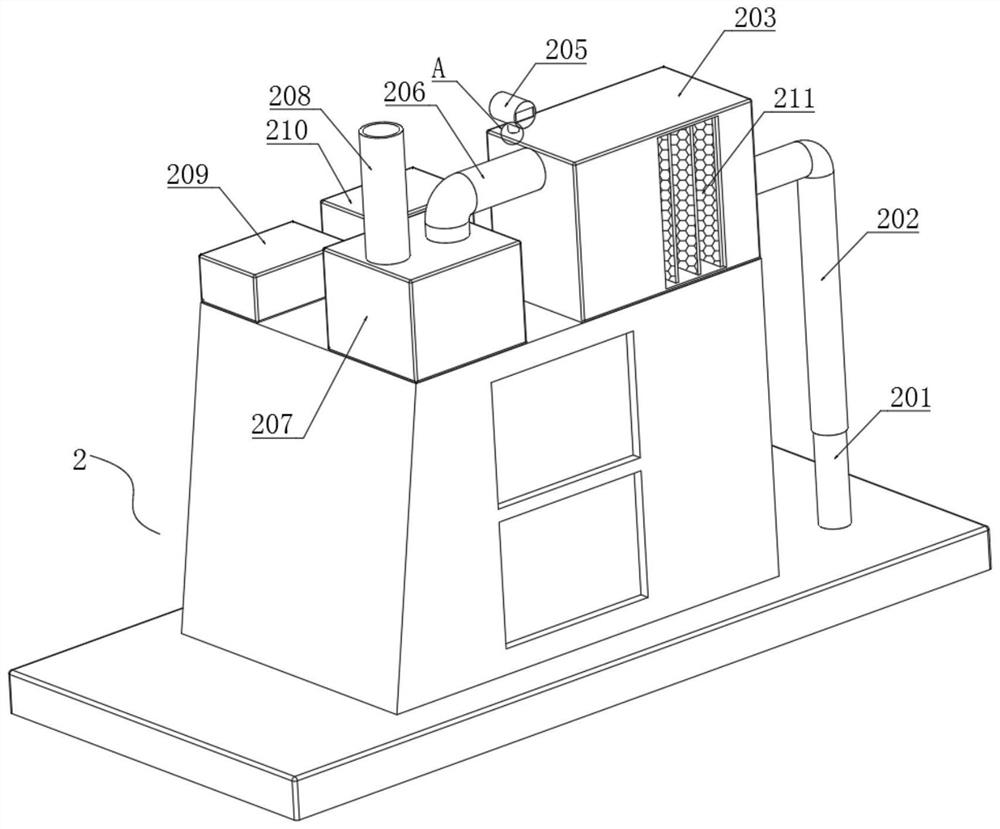

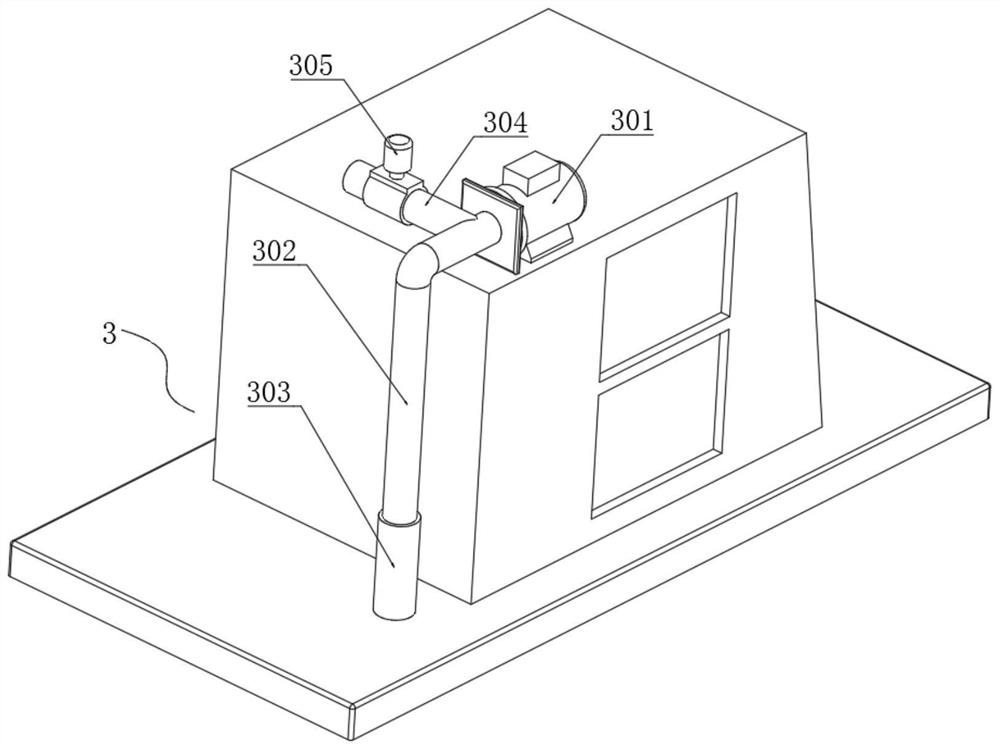

[0033] Example: as Figure 1-5 As shown, the present invention provides a technical solution, a tail gas purification device based on electric heating for tunnel construction machinery, comprising:

[0034] The purification component 2 is installed on the top of the loader 1, and the exhaust gas of the loader 1 is burned and then discharged through a chemical reaction through the purification box 207, so as to facilitate the maintenance of the construction environment and ensure the safety of the human body;

[0035] A purification assembly 2 is installed on the top of the loader 1. The purification assembly 2 includes an engine exhaust pipe 201, a heater pipe 202, an electric heating box 203, a through hole 204, a temperature sensor 205, a purification box pipe 206, a purification box 207, and a purification box row. Air pipe 208, controller 209, battery 210 and honeycomb heater 211;

[0036] The top side of the loader 1 is connected with an engine exhaust pipe 201, the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com