Moire fringes adjusting method for holographic grating making optical path

A holographic grating and Moiré fringe technology, applied in optics, optical components, instruments, etc., can solve the problems of high processing cost, affecting the quality of holographic grating, and difficult to eliminate the processing traces of aspheric devices, and achieve the effect of convenient and fast online detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

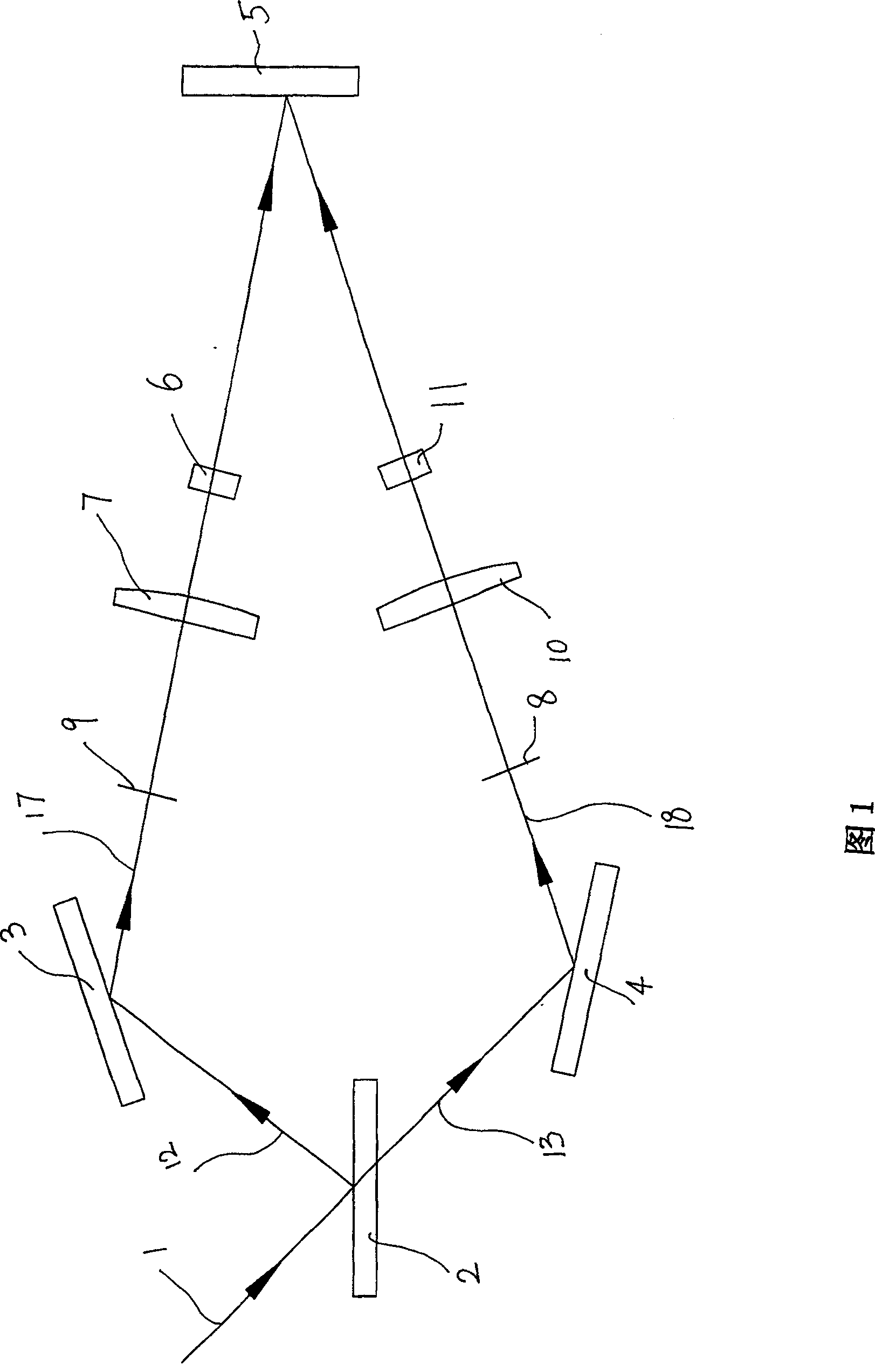

[0029] As shown in Figure 1, a method for adjusting moiré fringes in the optical path of a holographic grating comprises the following steps:

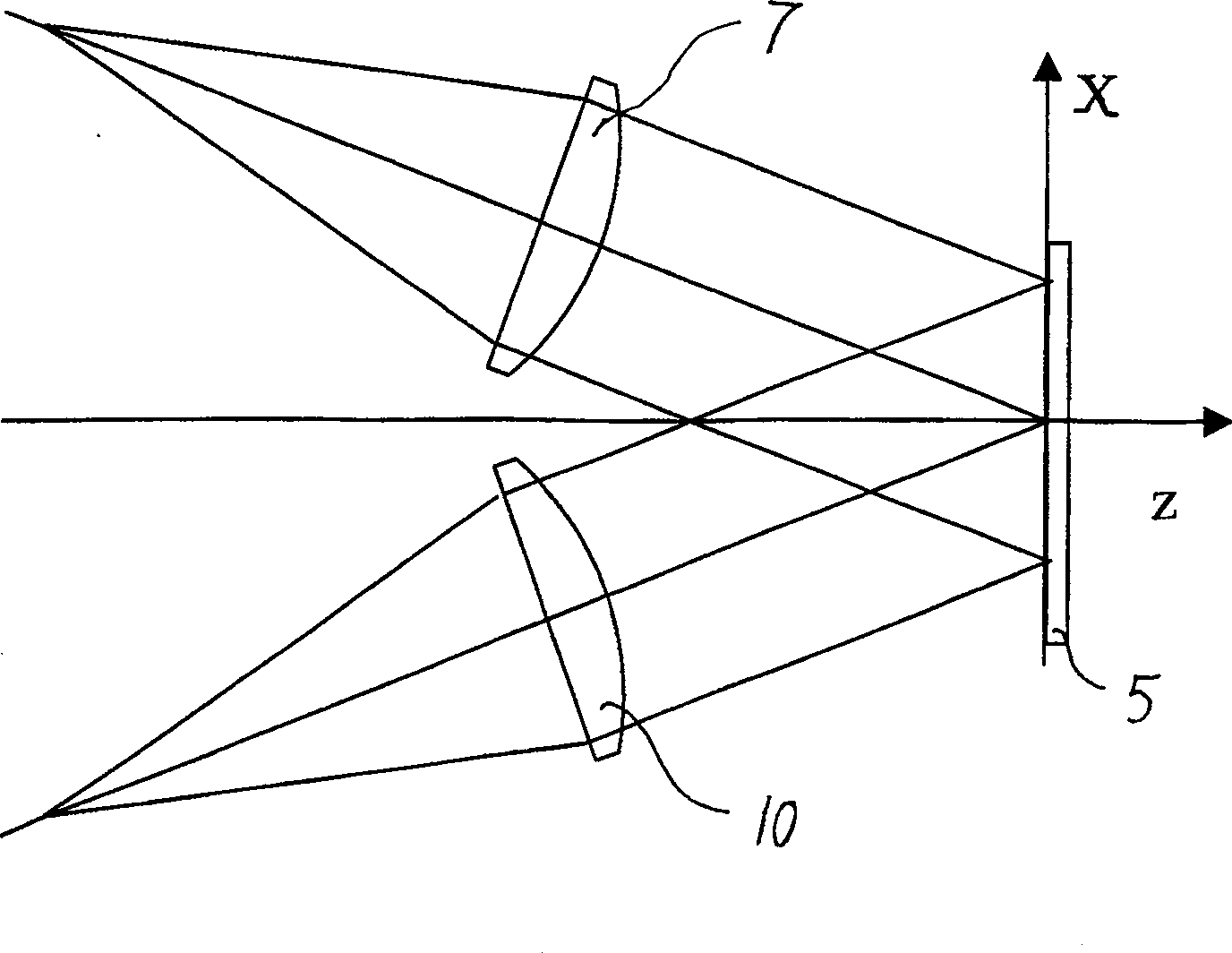

[0030] a. The beam splitter 2 divides the laser light 1 into object light 12 and reference light 13. The object light 12 is reflected by the main reflector 3 to form the main reflective light 17. The reference light 13 is reflected by the reference reflector 4 to form the reference reflective light 18. , both the main reflected light 17 and the reference reflected light 18 are irradiated on the holographic recording plate 5;

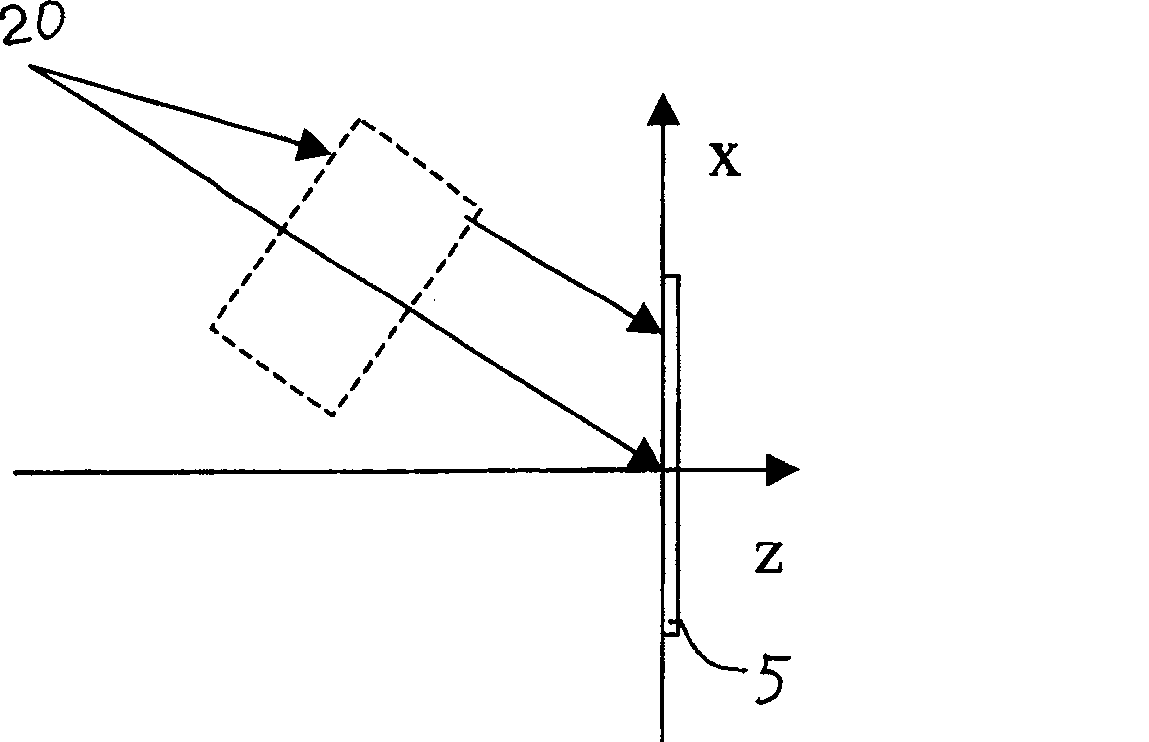

[0031] b. Adjust the positions of the main mirror 3, the reference mirror 4, and the holographic recording plate 5, so that the main reflected light 17 and the reference reflected light 18 are symmetrically incident on the holographic recording plate 5, and the main reflected light 17 and the reference reflected light 18 are recorded in the hologram. The incident angles on plate 5 all satisfy the formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com