Electronic package of light-sensitive semiconductor device and manufacturing and assembling method

A light sensing and semiconductor technology, applied in semiconductor devices, electric solid state devices, circuits, etc., can solve the problems of yield loss, complexity of structure and manufacturing process, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

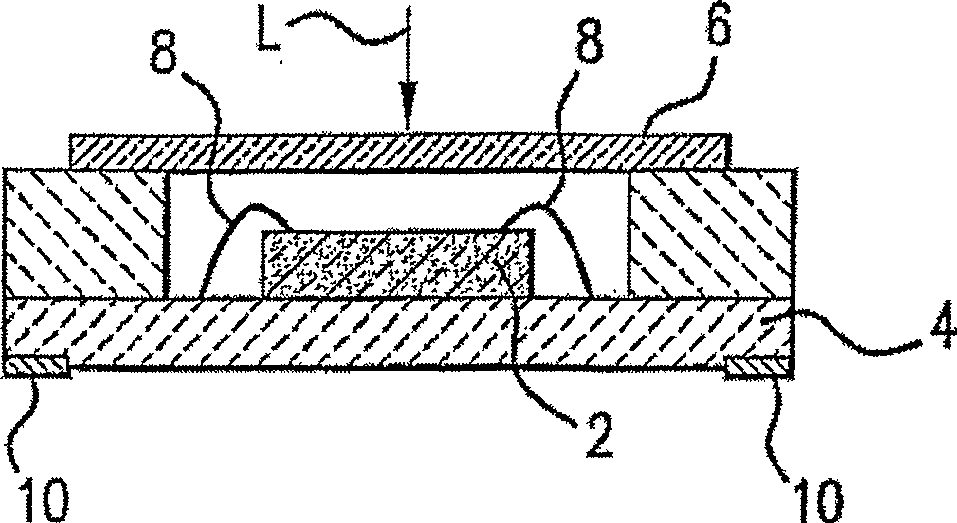

[0031] A photosensitive semiconductor wafer has a plurality of chips and, as in other semiconductor wafers, each chip has an integrated circuit formed on the front side of the wafer. Each chip has multiple bonding pads. The front side of the wafer has a patterned passivation layer to protect the underlying integrated circuits. There is an opening in the passivation layer on the welding pad. Each such photosensitive chip has at least one photosensitive area on the front side.

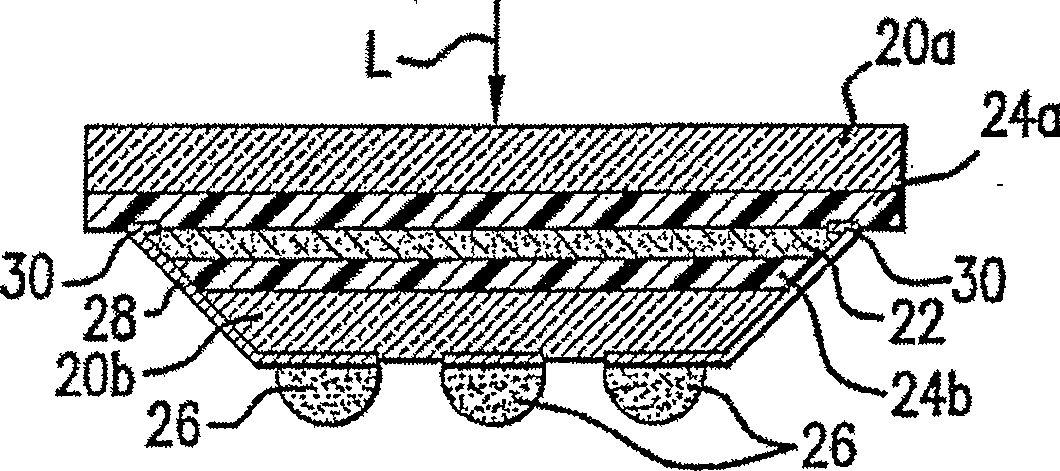

[0032]Wafer bumping technology is well known (as described in US Patent No. 3,292,240, later assigned to IBM, entitled "Method of Fabricating Microfunctional Components"), and has been widely used since its inception. A typical wafer bumping process includes at least one patterned metal layer to form solder bump pads that are attached to the pads of the wafer. Alloys used for solder bump pads are usually referred to as under-bump alloys (UBM) and are often multilayered to provide multiple functions su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com