Rubidium atomic frequency standard microwave cavity resonator

A technology of microwave resonant cavity and rubidium atomic frequency standard, which is applied in resonators, waveguide devices, electrical components, etc., can solve the problems of high processing precision, assembly and cavity frequency adjustment difficulties, and achieve easy cavity frequency adjustment and microwave filling The effect of large factor and uniform field shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

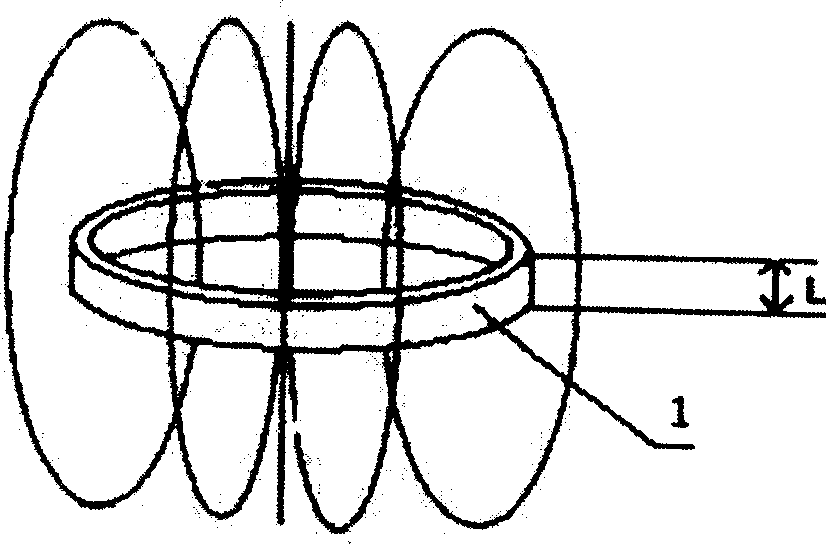

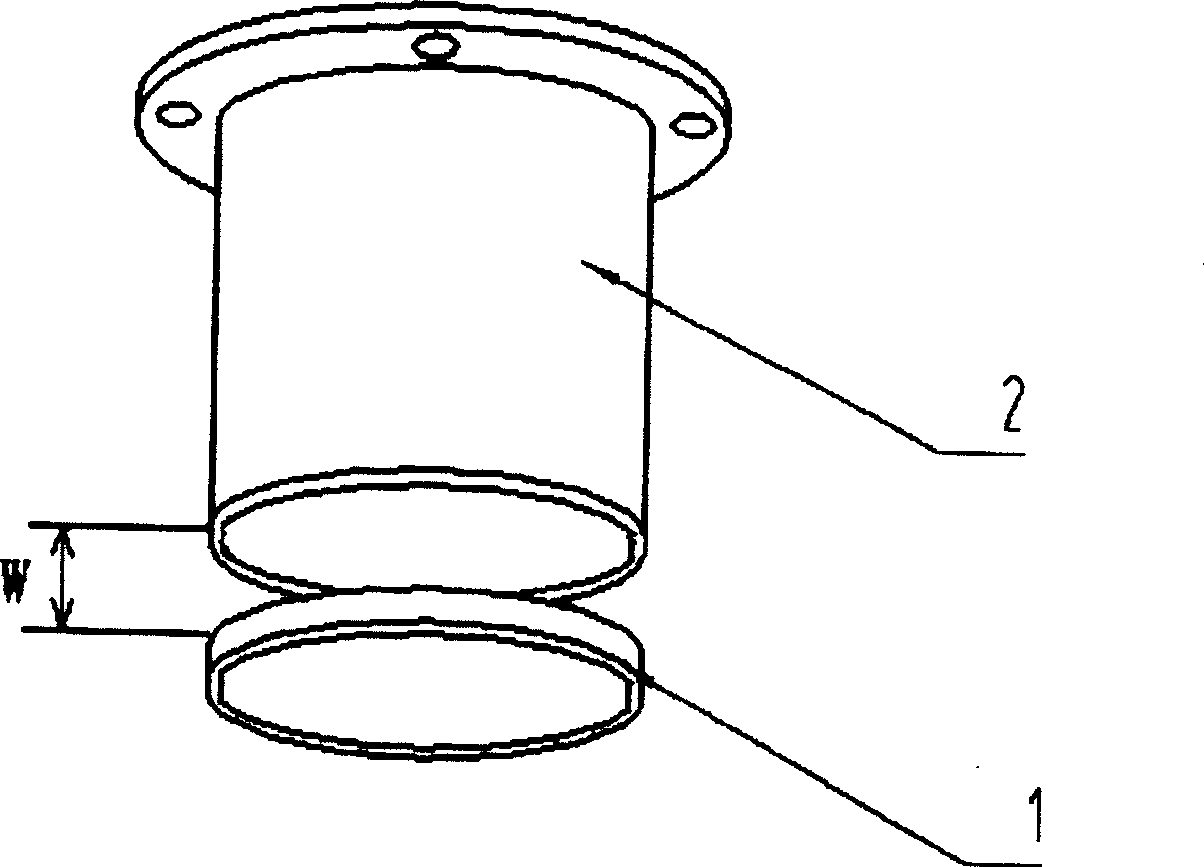

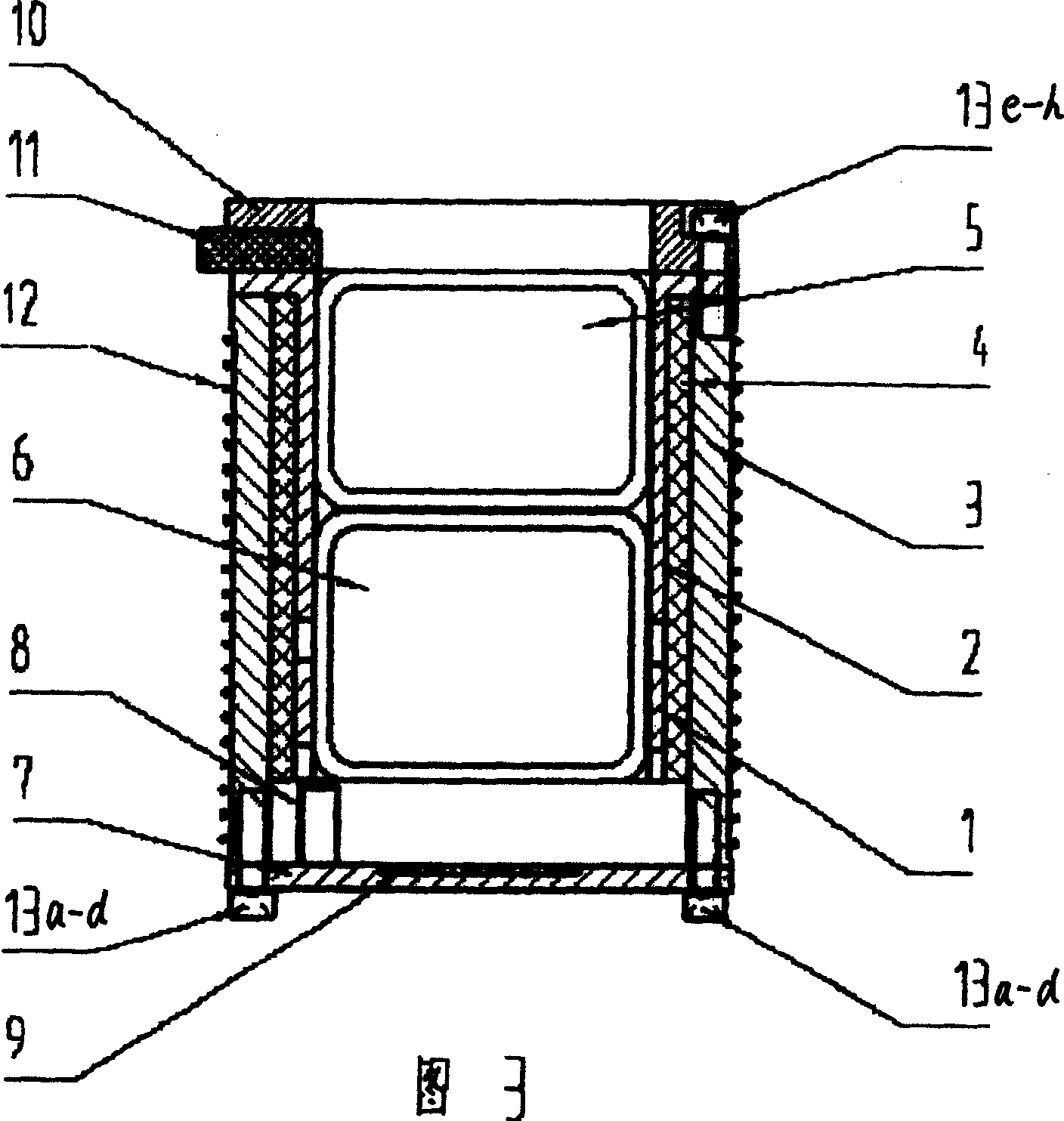

[0012] according to figure 1 , figure 2 , Figure 3 shows that the microwave resonant cavity used for rubidium atomic frequency standard consists of resonant ring 1, support tube 2, cylindrical cavity 3, dielectric ring 4, rubidium filter bubble 5, rubidium absorption bubble 6, end cover 7, coupling ring 8 , photocell 9, heating tube base 10, heating triode 11, C field coil 12, screws 13a-d, and screws 13e-h. The screws 13a-d are used to connect the end cover 7 and the cylindrical cavity 3, and the screws 13e-h are used to connect the heating tube base 10, the support tube 2 and the cylindrical cavity 3.

[0013] It is characterized in that: the rubidium filter bubble 5 and the rubidium absorption bubble 6 are closely fitted and inserted into the support tube 2, and both are filled with an appropriate amount of isotope rubidium and a buffer gas with a certain composition and ratio. The support tube 2 is made of metal material (such as aluminum alloy) and is used to support t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com