Roller cleaning system

A roller, clean technology, applied in furnace components, furnace types, furnace control devices, etc., can solve problems such as cumbersome economical angle and cumbersome time angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

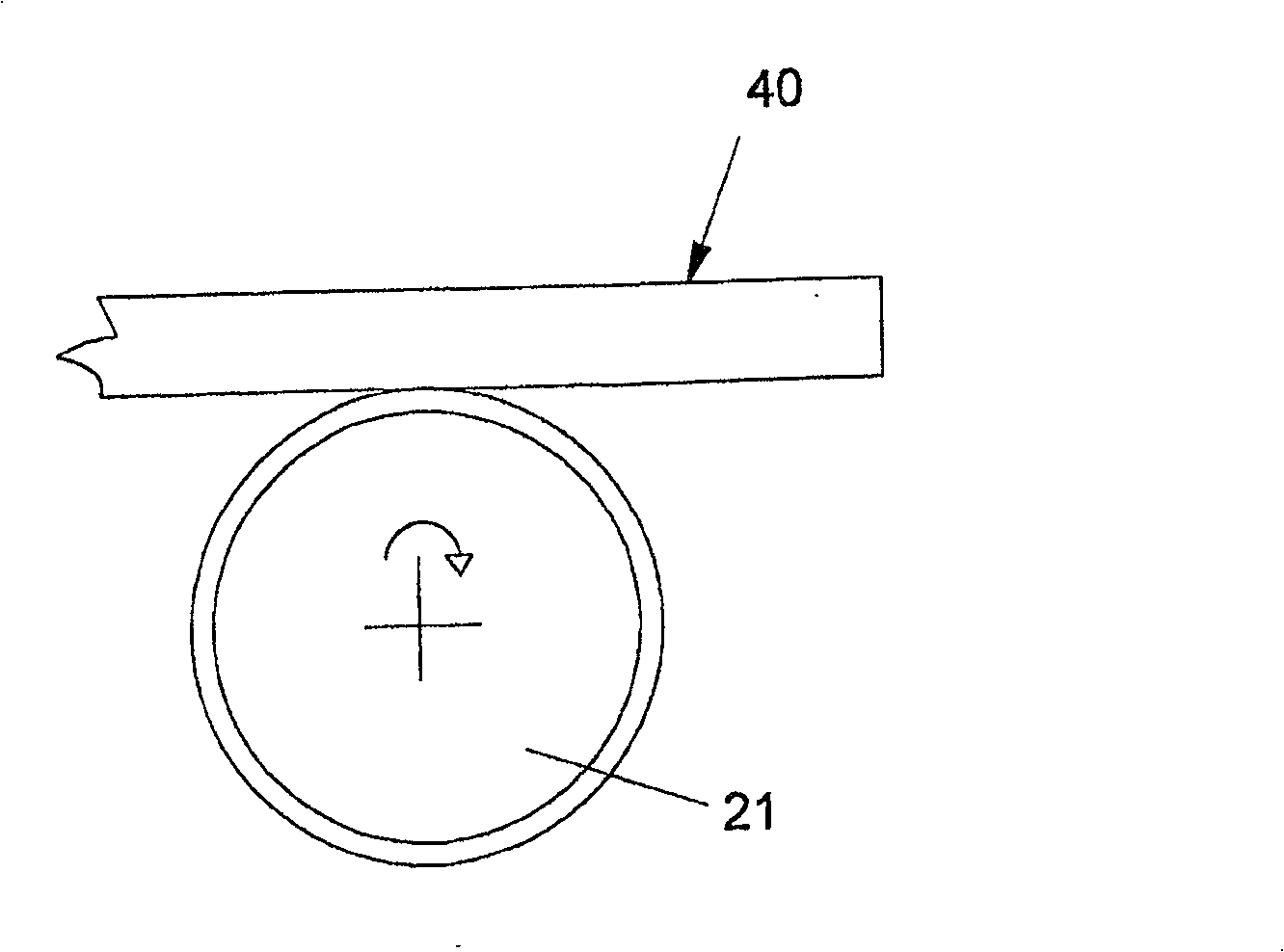

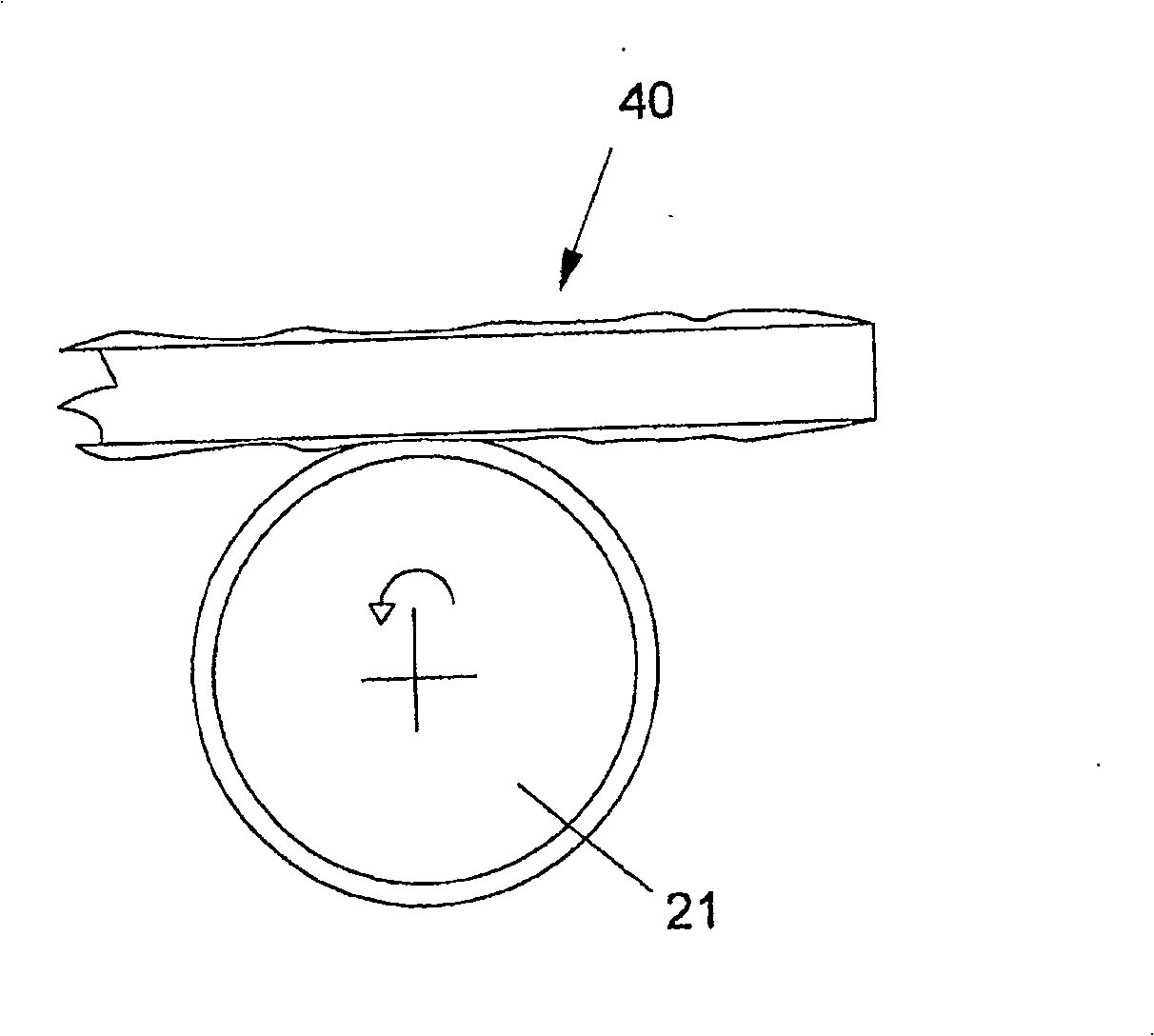

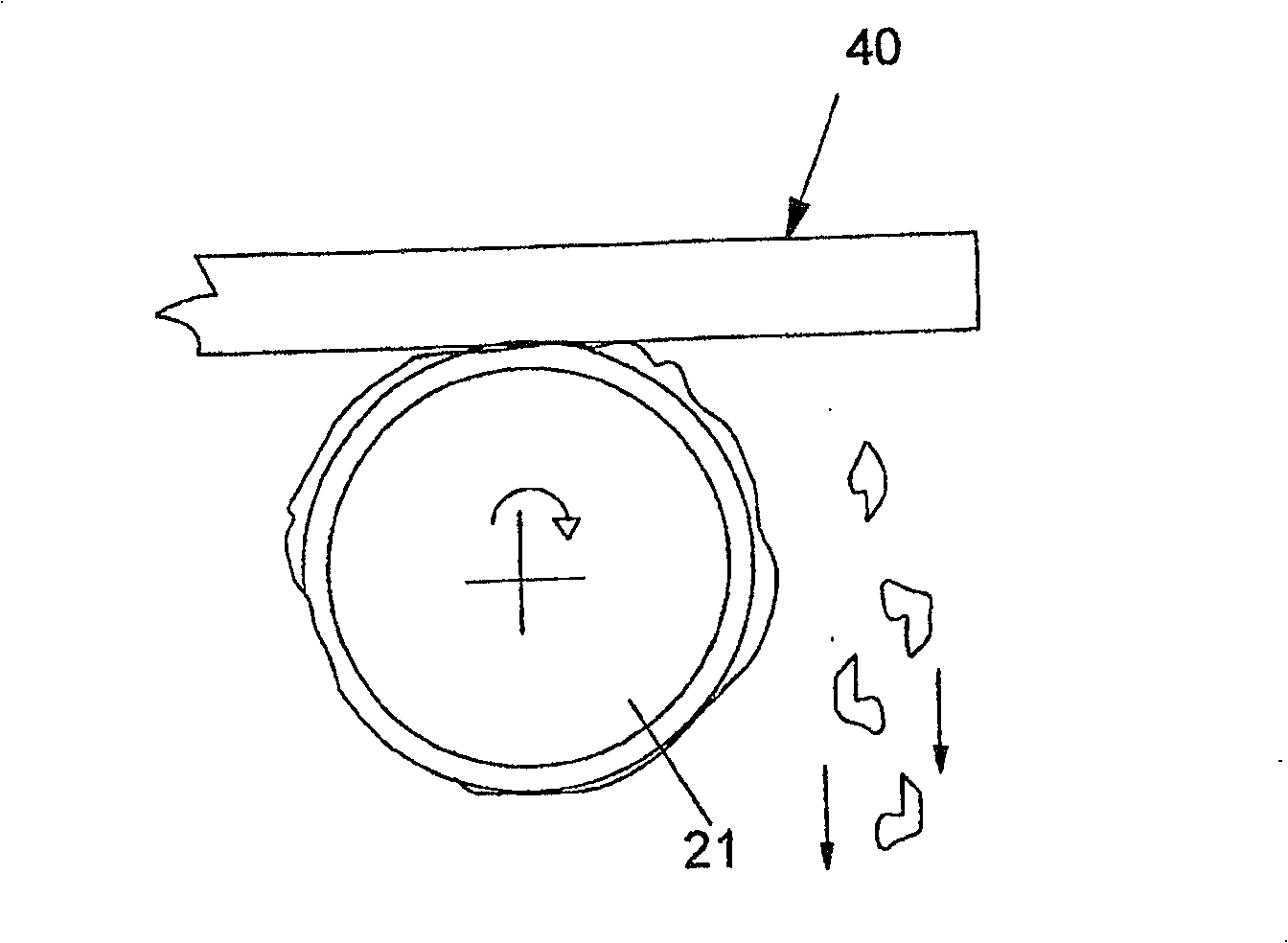

[0037] Referring to the accompanying drawings, with 10 indicating the whole of the roller cleaning system, in the embodiment shown, the roller cleaning system according to the invention comprises a control and regulation unit 14, which preferably communicates with Relevant control and excitation devices 26 are connected, such as PLC, and each relevant control and excitation device is connected with the motor 24 of each roller 21 through a frequency converter 25 (inverter), and the frequency converter controls the rotation speed of the motor 24 itself.

[0038] The cleaning system 10 is applied in a roller oven 20 equipped with a series of rollers 21 driven in rotation by individual motors 24 .

[0039] According to a preferred embodiment of the present invention, the roller cleaning system 10 is able to independently drive each mechanized roller of the series of rollers 21 through the control and regulation unit 14 and can be combined with other mechanized rollers of the series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com