Method and device for winding several threads

A technology of strand length and driving device, applied in the field of devices implementing the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

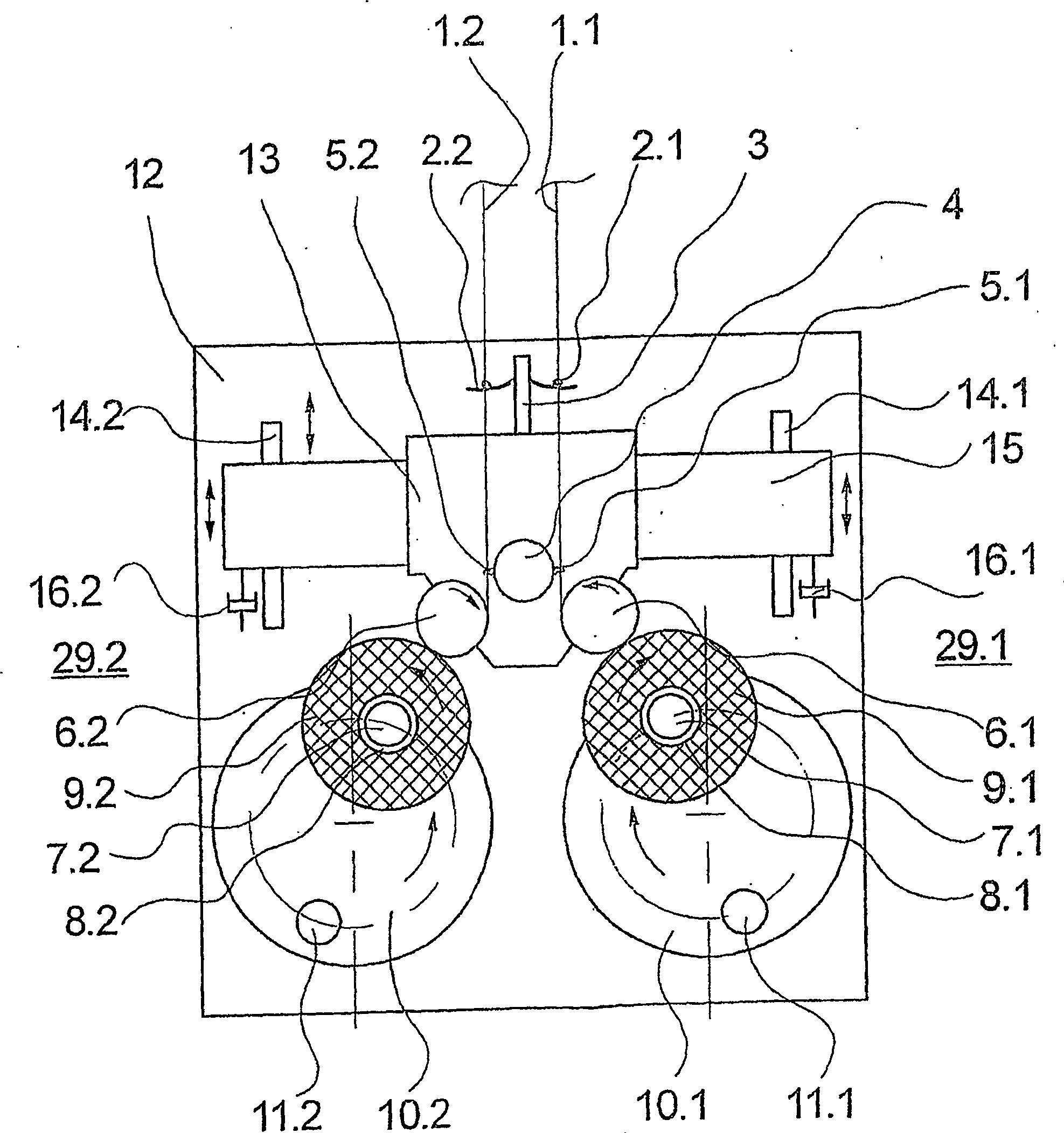

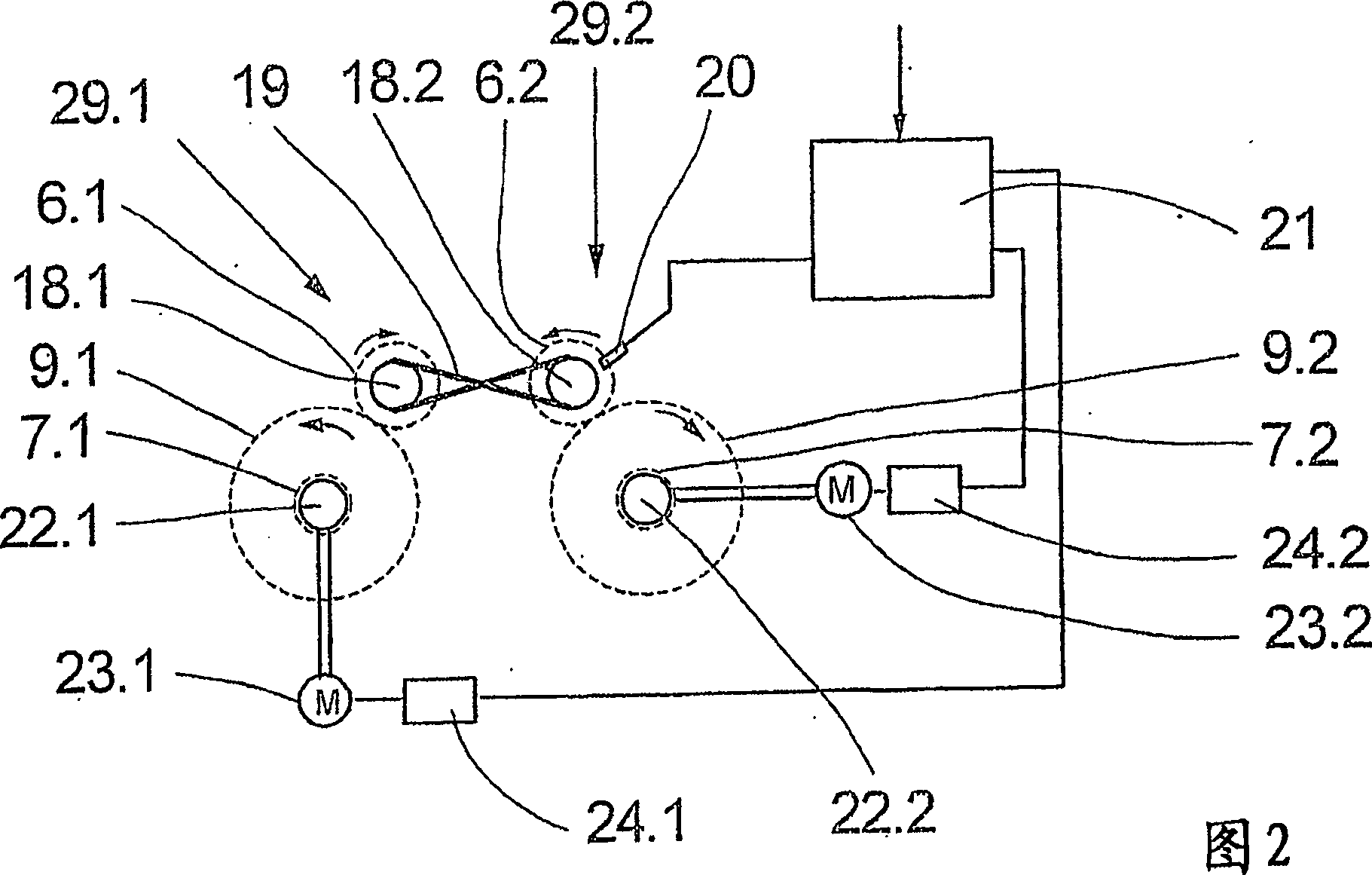

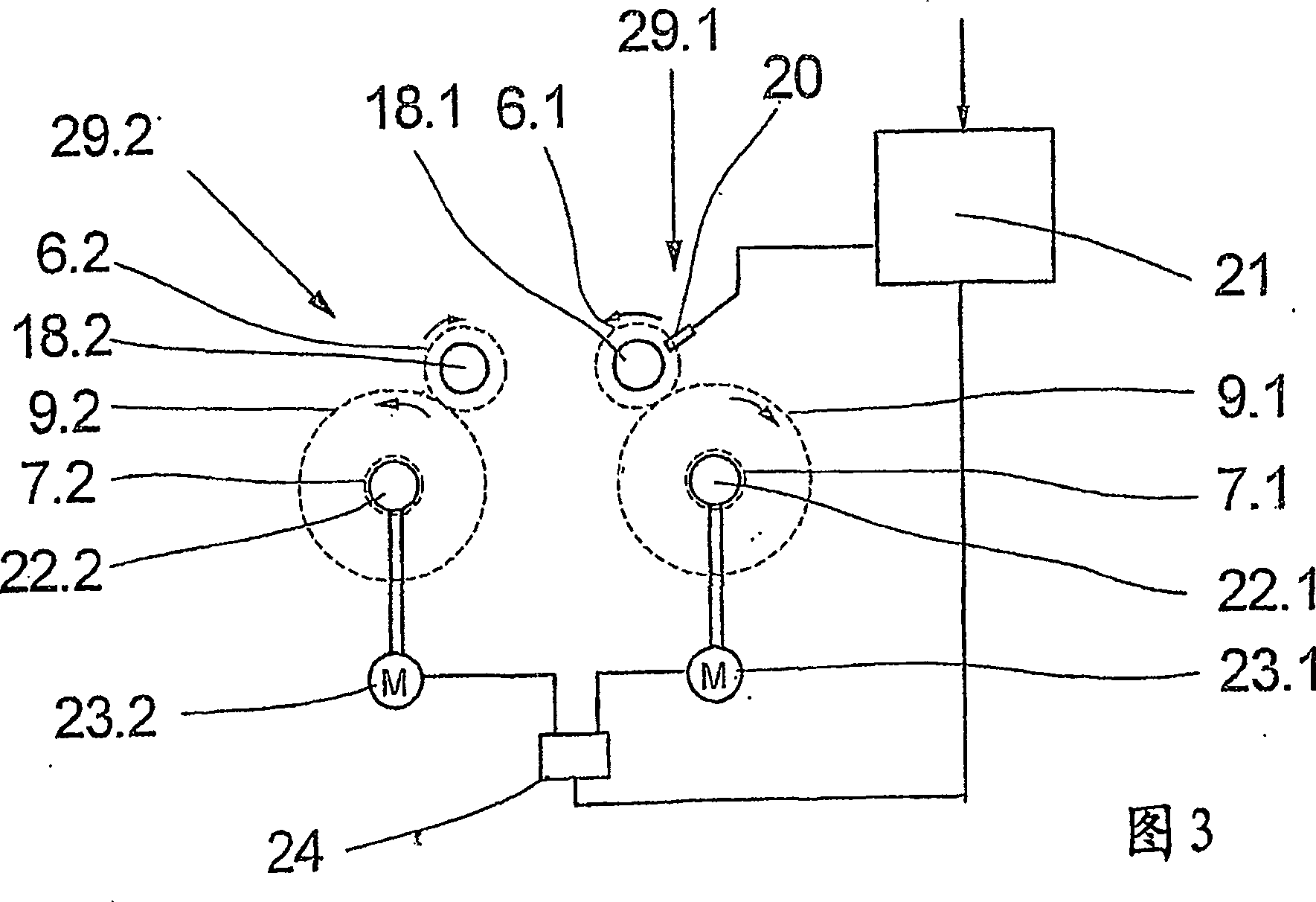

[0025] exist figure 1 A first embodiment of the apparatus according to the invention for carrying out the method according to the invention is shown in and 2 . in figure 1 A front view of this embodiment is shown, and FIG. 2 shows a schematic rear view thereof.

[0026] first by means of figure 1 The structure of this embodiment will be described.

[0027] This exemplary embodiment of the device according to the invention has two winding locations 29.1 and 29.2 which are arranged side by side in a machine frame 12. In this case, the winding locations 29.1 and 29.2 are formed mirror-symmetrically with respect to a central symmetry plane. For example, the winding position 29.1 consists of a spindle frame 10.1 rotatably supported on the frame 12, a cantilevered first bobbin spindle 7.1 is supported on the spindle frame 10.1, and a cantilevered first bobbin spindle 7.1 is supported at an offset of 180°. Two bobbin spindles 11.1. Here the first bobbin spindle 7.1 is in the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com