Low temp sintered ZnO multilyer pressure sensitive resister and manufacturing method thereof

A varistor, low-temperature sintering technology, applied in varistor cores, resistance manufacturing, varistors, etc., can solve the problems of low cost, high cost, and poor reliability of varistors, and achieve production saving Steps, low cost, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

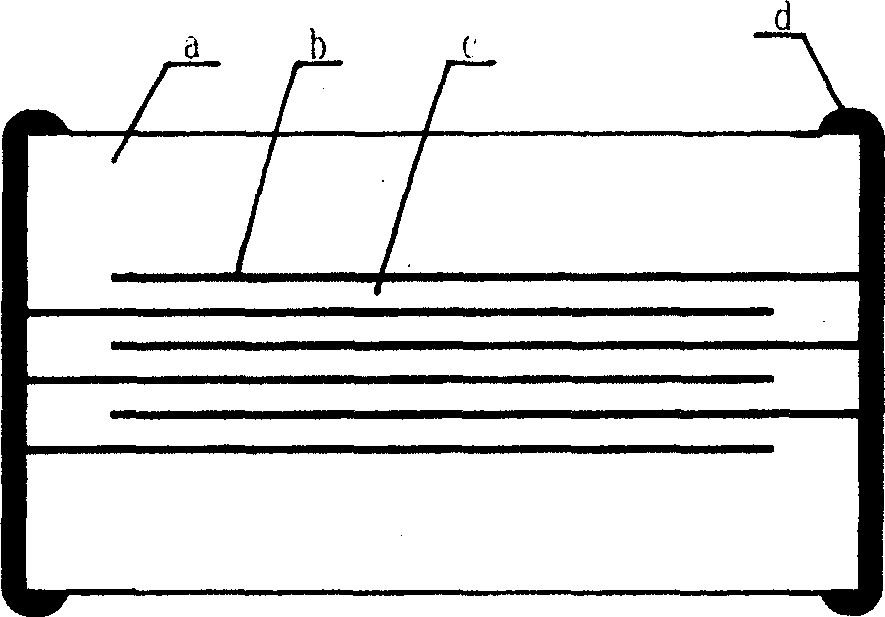

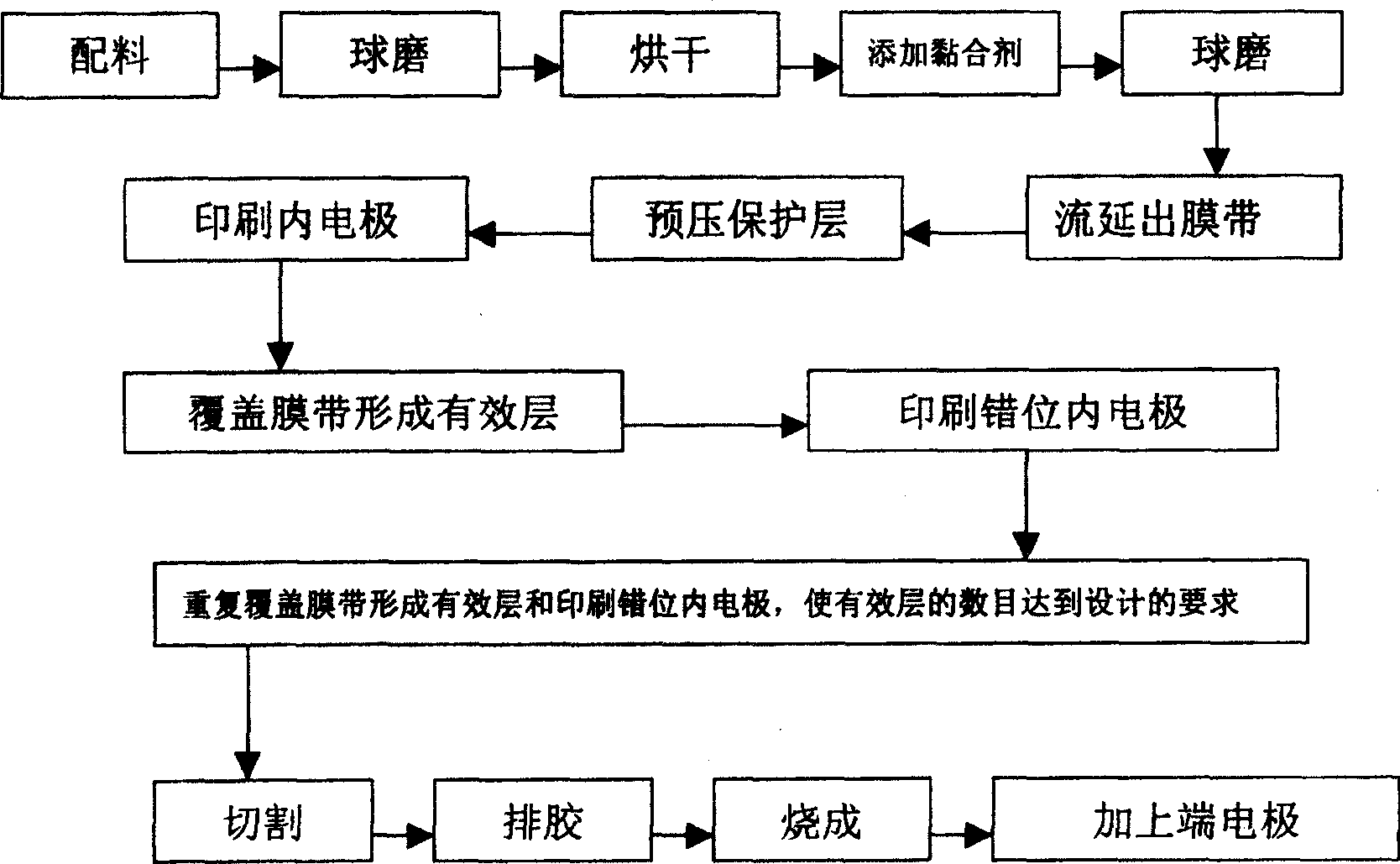

[0040] Such as figure 1 structure shown, figure 2 The manufacturing method flow shown, and according to the formula table 1, accurately weigh various materials, put the weighed materials into a high-efficiency ball mill, add an appropriate amount of deionized water and zirconium balls, and ball mill for 12 hours to obtain an average particle size of 0.4 micron material. Put the ball-milled material in a stainless steel tray and dry it at about 120°C for 10 hours, then add an appropriate amount of prepared adhesive, and then ball-mill for 24 hours to make a uniform and stable casting slurry, and then cast the film tape, and slightly press the film tape to obtain a film tape protective layer a with a thickness of 45 microns, and print an alloy internal electrode b with a weight ratio of 95% silver and 5% palladium on the film tape protective layer a, and then dislocate after lamination Print another layer of internal electrodes until the effective layer c is 6 layers, cut out...

Embodiment 2

[0044] Accurately weigh various materials according to formula table 2. Put the weighed material into a high-efficiency ball mill, add an appropriate amount of deionized water and zirconium balls, and ball mill for 12 hours to obtain a material with an average particle size of 0.2 microns. Put the ball-milled material in a stainless steel tray and dry it at about 120°C for 10 hours, then add an appropriate amount of prepared binder, and then ball-mill for 24 hours to obtain a uniform and stable casting slurry. Cast out the film tape, and slightly press the film tape to obtain a film tape protective layer with a thickness of 15 microns. Print an alloy internal electrode with a weight ratio of 90% silver and 10% palladium on the protective layer of the film tape, and then print another layer of internal electrodes in dislocation after lamination until the effective layer is 6 layers. After hydrostatic pressure, cut out green bodies with a size of 04×02 (inches), put these green...

Embodiment 3

[0048] Accurately weigh various materials according to formula table three. Put the weighed material into a high-efficiency ball mill, add an appropriate amount of deionized water and zirconium balls, and ball mill for 12 hours to obtain a material with an average particle size of 0.10 microns. Put the ball-milled material in a stainless steel tray and dry it at about 120°C for 10 hours, then add an appropriate amount of prepared binder, and then ball-mill for 24 hours to obtain a uniform and stable casting slurry. The film tape was flow cast, and the film tape was slightly pressed to obtain a film tape protective layer with a thickness of 55 microns. Print an alloy internal electrode with a weight ratio of 96% silver and 4% palladium on the protective layer of the film tape, and print another layer of internal electrodes in dislocation after lamination until the effective layer is 6 layers. After hydrostatic pressure, cut out green bodies with a size of 04×02 (inches), put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com