Linear sliding rail holder

A technology of linear slides and retainers, used in linear motion bearings, large fixed members, bearings, etc., can solve the problems of difficult demoulding, poor oil lubrication, large friction, etc., and achieve high production yield and oil. Excellent fluid lubrication and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

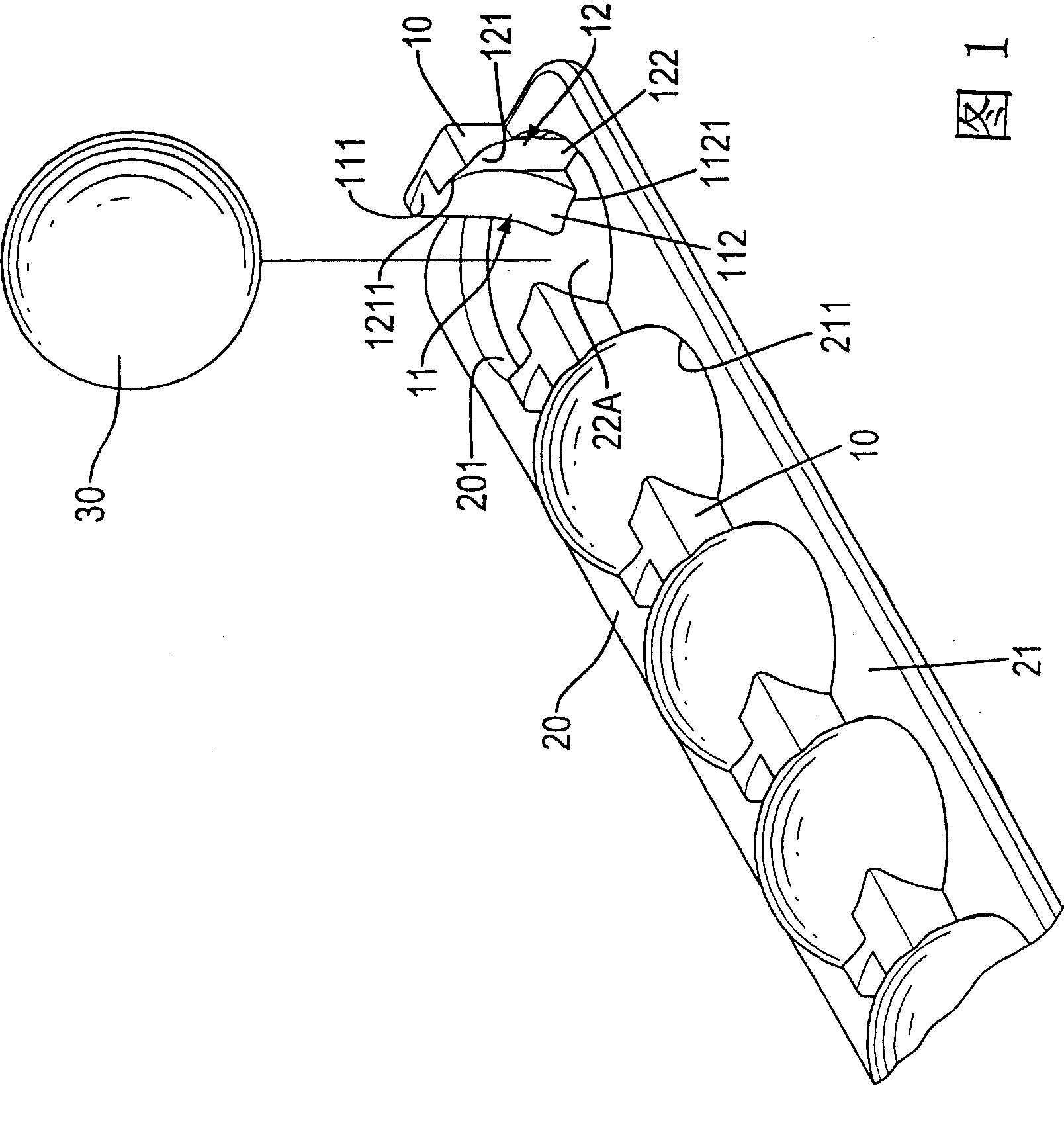

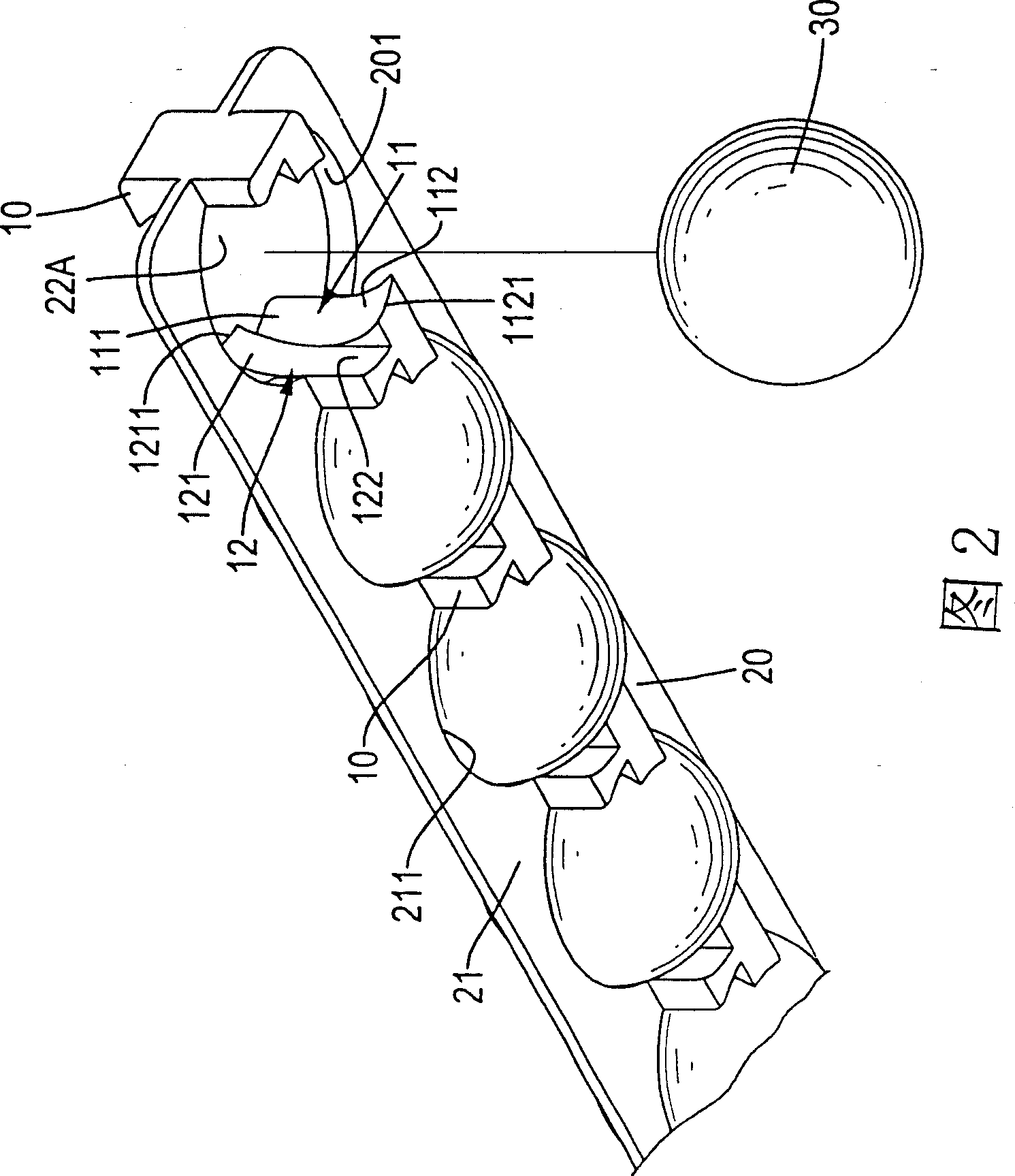

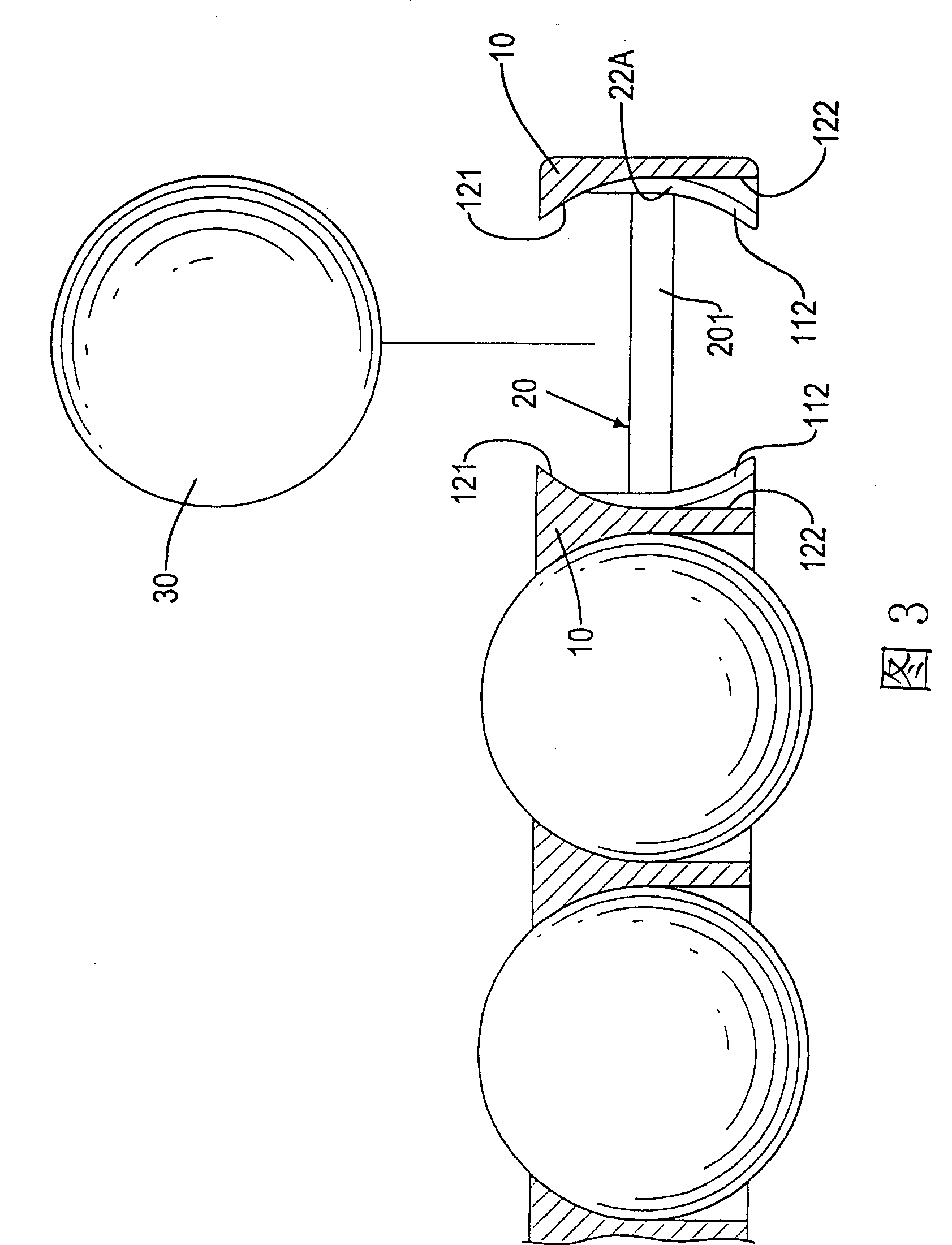

[0052] The present invention is a kind of linear sliding rail retainer, which mainly locates a plurality of rolling components embedded in it by staggered claw surfaces.

[0053] Please refer to the first preferred embodiment of Fig. 1 to Fig. 3, it is provided with a plurality of spacers 10 facing and spaced apart from the front and back, a first connecting band 20 respectively combined in the left end of each spacer 10, and One is respectively combined with the second connecting band 21 at the right end of each spacer 10, wherein:

[0054] Each spacer 10 is a rectangular block arranged in a vertical direction, and is provided with a first straight restraint surface 11 and a second straight restraint surface 12 on the opposite surface from left to right, the first direct restraint surface 11 is rectangular and The upper and lower sides are each a vertical first flat surface 111 and an arc-shaped first claw surface 112, the second straight restraint surface 12 is rectangular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com