Track circuit point front integral adjustment instrument

A comprehensive adjustment, circuit point technology, applied in electronic circuit testing, railway signals, railway car body components, etc., can solve the problems of driving interference, long replacement time, unsafe driving, etc., to reduce driving interference, reduce The cost of human and material resources and the effect of reducing the number of points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

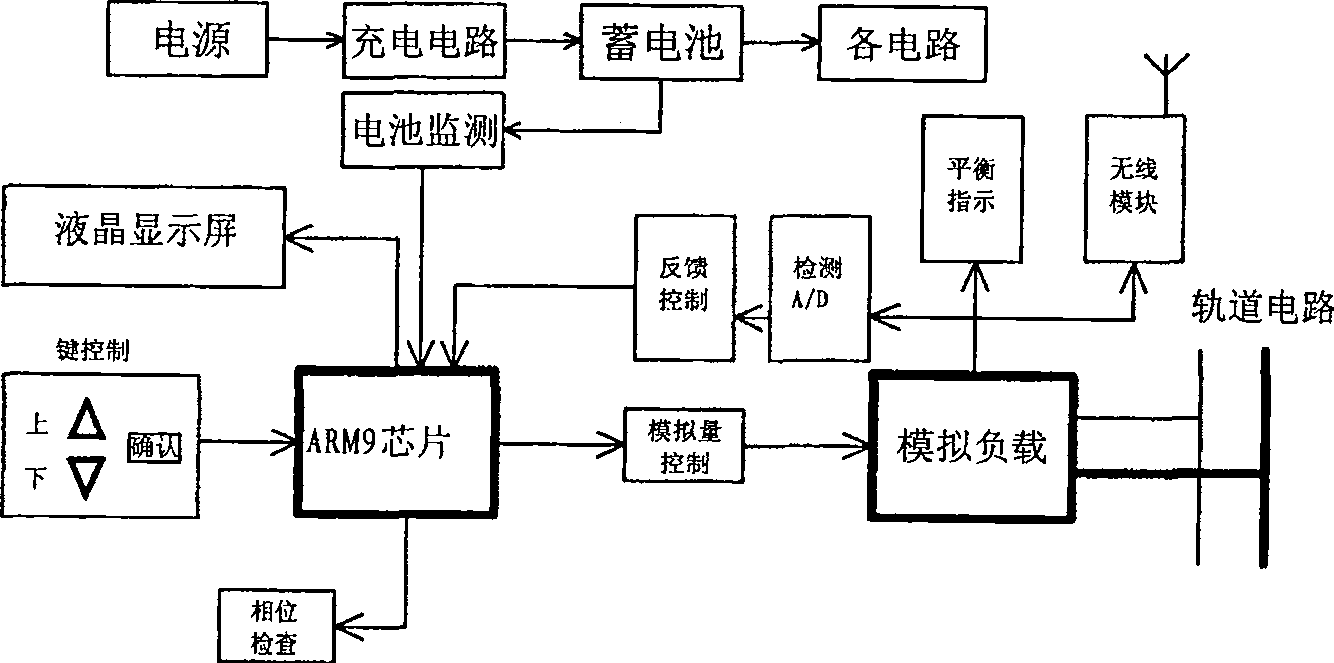

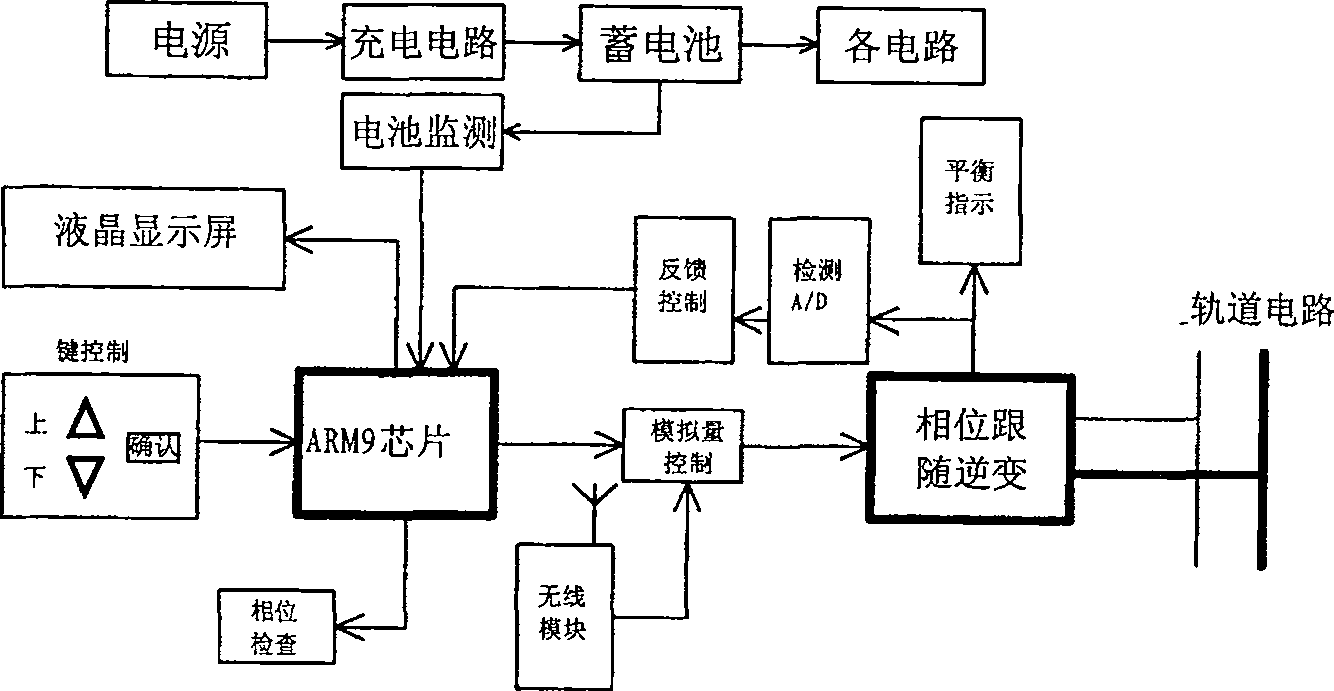

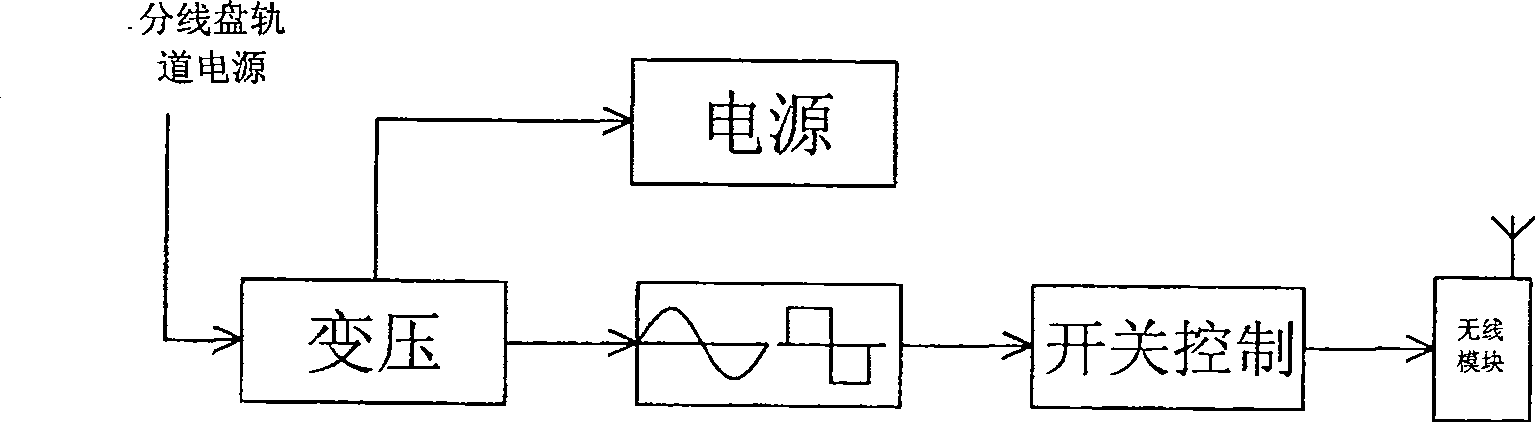

[0011] As shown in the figure, the comprehensive adjustment instrument before the track circuit point of the present invention includes a host and an extension, the host includes a first power supply that provides electric energy to the host, and a first microprocessor is connected to the first microprocessor respectively. The first display of the device output port, the first phase inspection circuit, and the first analog control circuit; the output end of the first analog control circuit is electrically connected to the input end of the analog load circuit; the output end of the analog load circuit is electrically connected to the track circuit ; The input end of the first microprocessor is respectively connected with the first power monitoring circuit, the first feedback control circuit, and the first button control circuit; the input end of the first feedback control circuit is electrically connected with the first A / D detection circuit, so The input end of the first A / D de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com