Outer tube of exhaust system part

A technology of exhaust system and components, which is applied in the field of the outer cylinder of exhaust system components, can solve the problems of damaging the waterproof effect of the outer cylinder, and achieve the effect of preventing exhaust gas leakage and suppressing bulging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

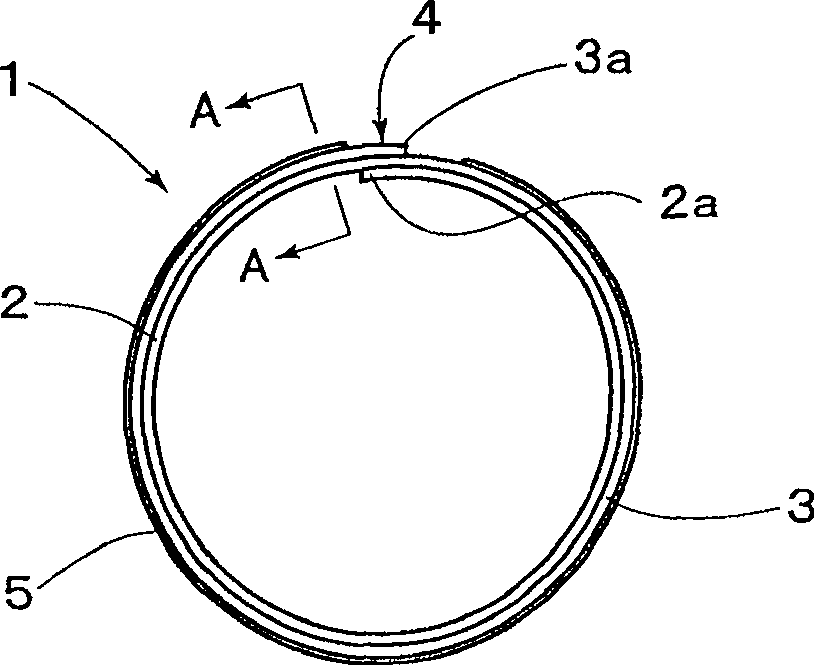

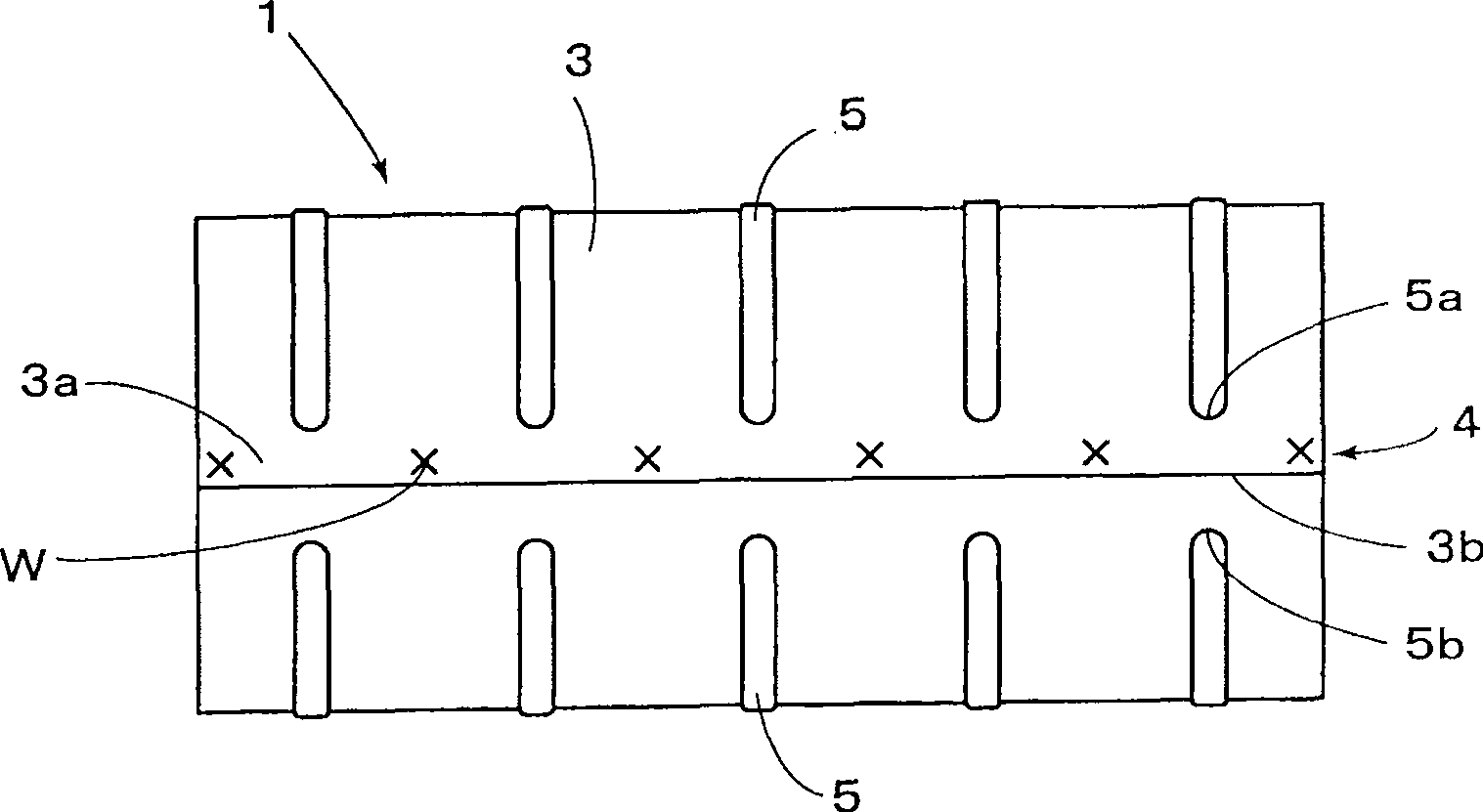

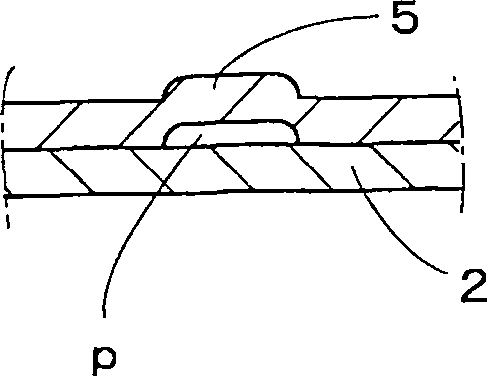

[0037] Preferred embodiments of the present invention will be described below with reference to the drawings. Figure 1 to Figure 3 It is a figure which shows the outer cylinder 1 of the exhaust system component which concerns on one Embodiment of this invention, image 3 yes figure 1The enlarged sectional view of A-A. Such as figure 1 and figure 2 As shown, the outer cylinder 1 is double-wound metal plates to form a cylindrical shape composed of an inner plate 2 and an outer plate 3, and the circumferential end 2a of the inner plate 2 is aligned with the circumferential edge of the outer plate 3. The end portions 3a of the overlapping portions 4 are intersected in the circumferential direction, and the overlapping portions 4 are connected together, and formed in two layers. The circumferential end portion 2a of the inner plate 2 and the circumferential end portion 3a of the outer plate 3 are formed in close contact with each other at the overlapping portion 4 and are smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com