Radial insulation laminated conductive slip ring

A conductive slip ring and laminated technology, which is applied in the field of electromechanical devices, can solve the problems of thin-walled insulating sleeve processing difficulties, reduce stiffness, and increase the radial size of the slip ring with the insulating sleeve, so as to avoid precision machining and increase The effect of rigidity and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

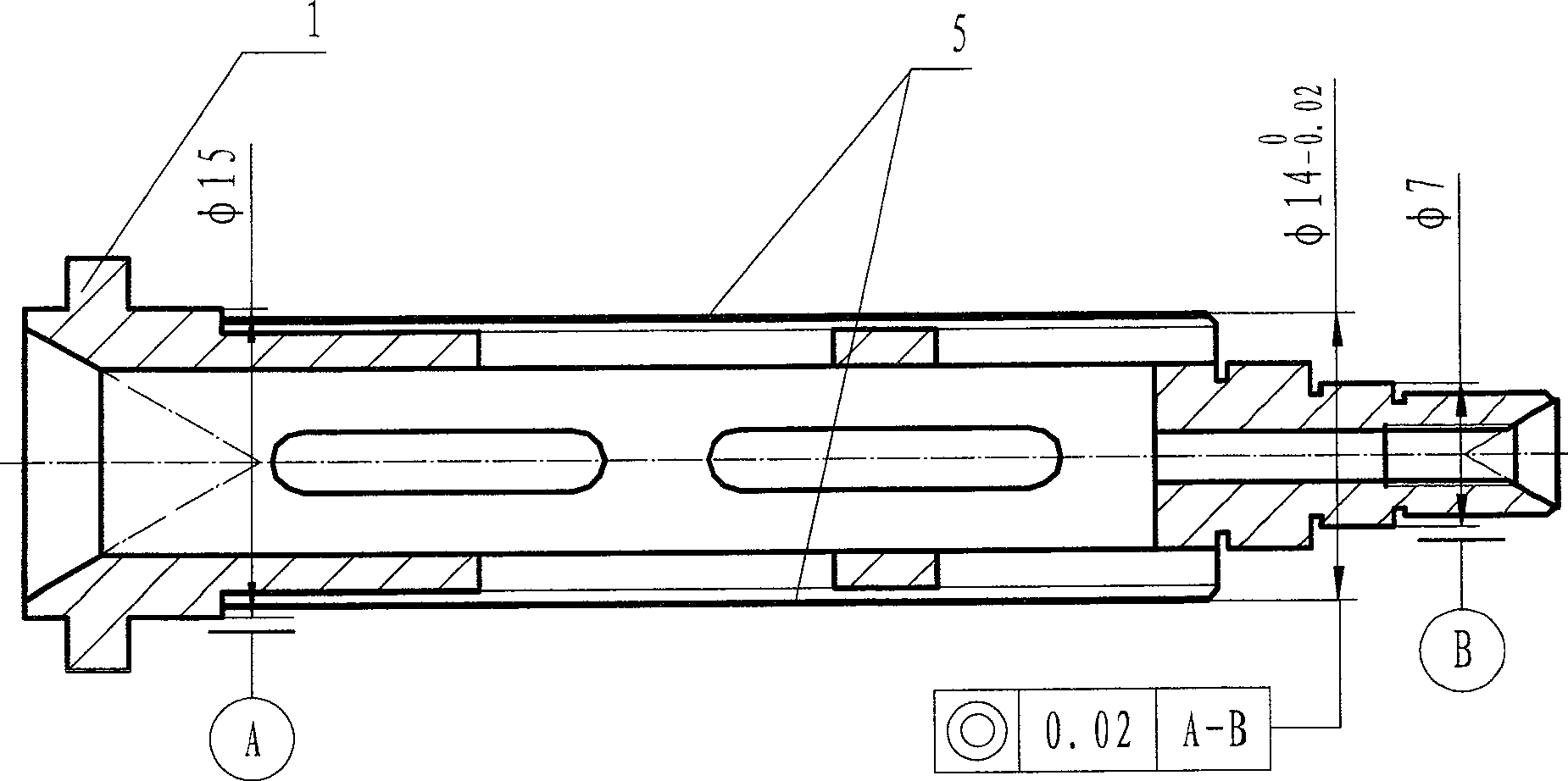

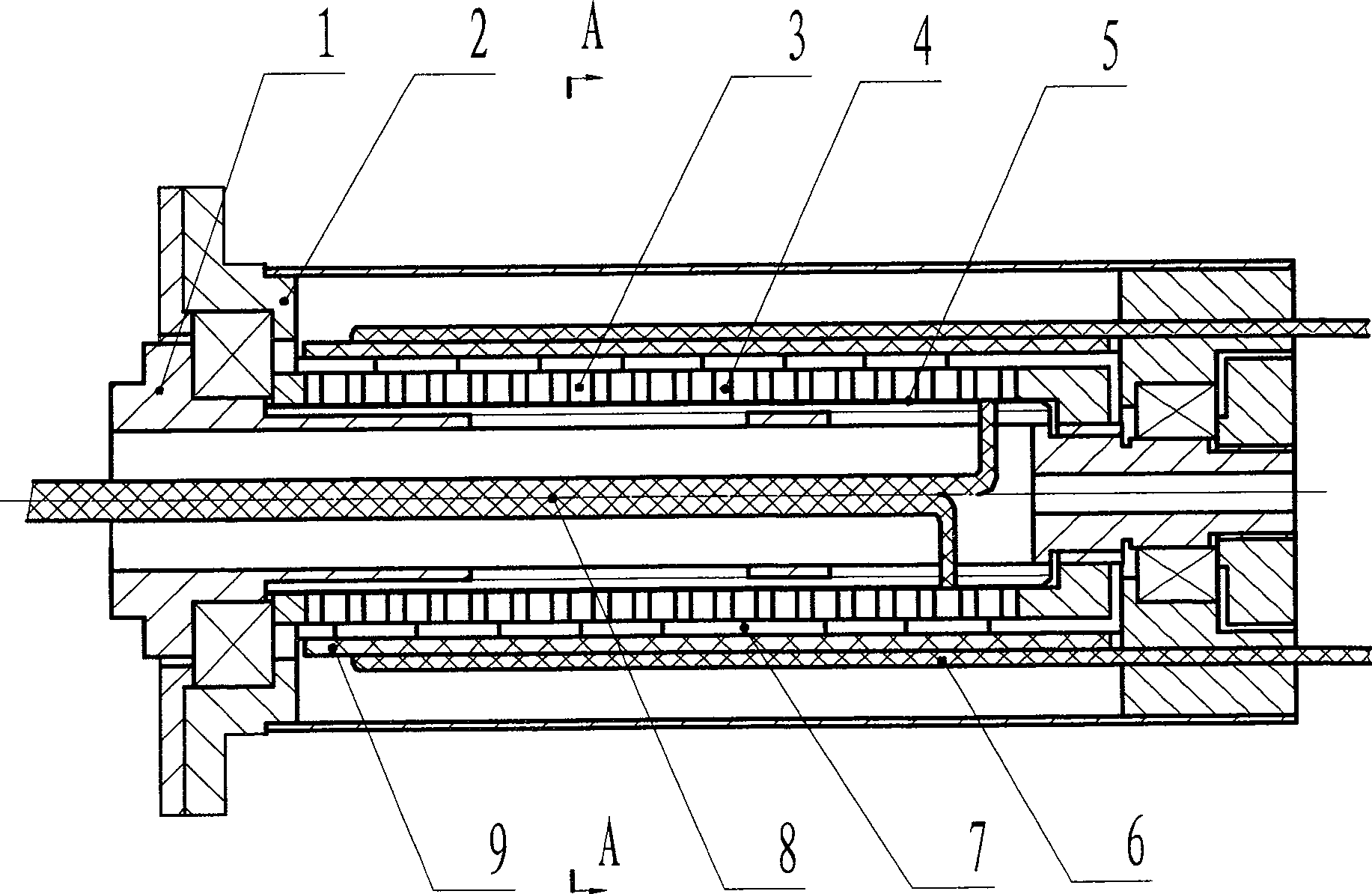

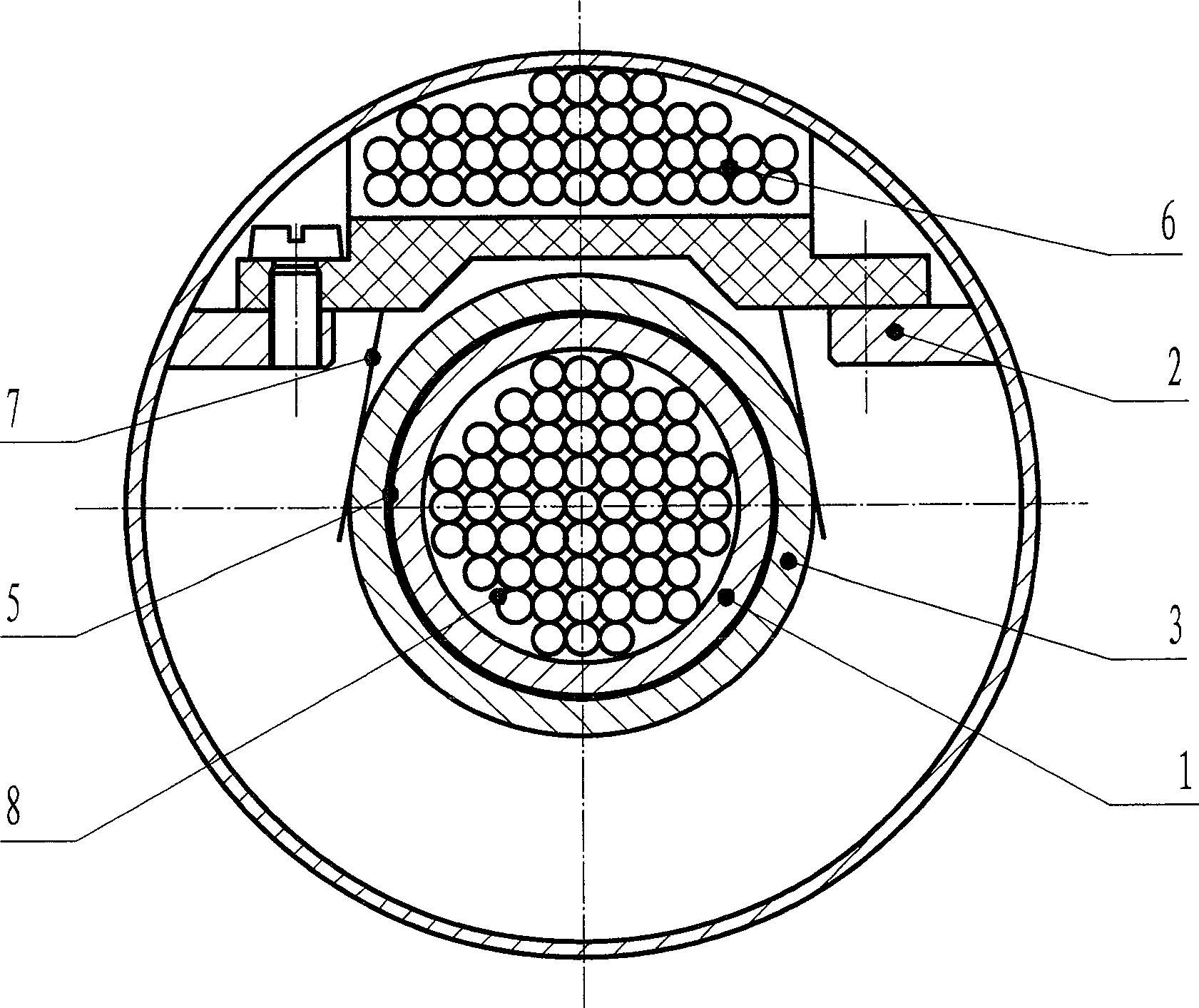

[0013] Now to process a conductive slip ring shaft with a diameter of φ14mm, first divide the slip ring shaft 1 into two sections, and set the wiring grooves for the lead wires 8 of the conductive ring pieces at a radial difference of 90°. The hollow interior of the shaft is connected, and the slip ring is on the shaft If the outer circle is semi-finishing to φ13.7mm, then the reserve for coating thickness is 0.15mm;

[0014] Spray liquid Teflon polymer insulating material on the outer circle of the slip ring shaft, and cure it at a high temperature of 350°C. The two processes of spraying and curing are carried out alternately 5 times, and the temperature of high temperature curing is controlled at 350±10°C to prevent The shaft is deformed, and the thickness of the coating is left with a finishing allowance of 0.05mm;

[0015] Then, the φ15 and φ7 outer circles on the slip ring shaft are ground and finished. The outer circle is ground and finished to achieve The dimensio...

Embodiment 2

[0019] Now to process a conductive slip ring shaft with a diameter of φ14mm, first divide the slip ring shaft 1 into 10 sections, and set the wiring groove for the lead wire 8 of the conductive ring piece on the same straight line, the hollow of the wire groove and the slip ring shaft internal communication, slip ring on shaft If the outer circle is semi-finishing to φ13.4mm, then the reserve for coating thickness is 0.3mm;

[0020] Secondly, spray liquid machinable glass-ceramic polymer insulating material on the outer circle of the slip ring shaft, and cure it at a high temperature at 200°C. The two processes of spraying and curing are carried out twice respectively, and the coating thickness is left with a finishing allowance of 0.08mm;

[0021] Then, the φ15 and φ7 outer circles on the slip ring shaft are ground and finished. The outer circle is turned and finished to achieve The dimensional tolerance requirements and the 0.02mm coaxiality requirements with the φ15 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com