Extrusion-die pressing precise forming method and apparatus therefor

A technology of precision molding and extrusion die head, applied in the field of extrusion-molding precision molding, it can solve the problems that the control conditions and operation processes cannot be strictly the same, it is difficult to ensure the precision of precision products, and it is difficult to precisely shape, etc. The effect of shortened molding cycle and continuous molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

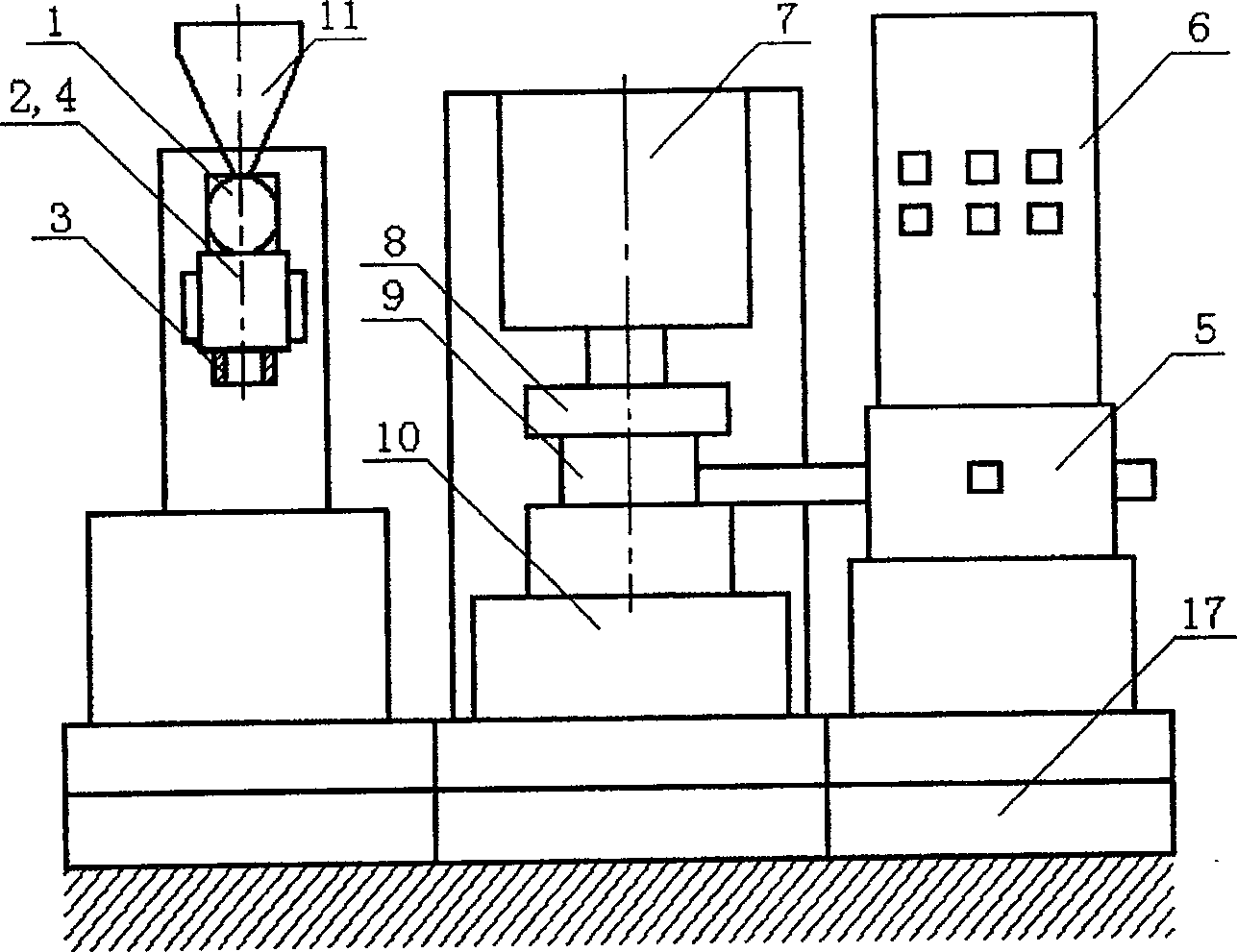

[0024] Such as figure 1 , 2 , 3, the equipment is composed of three parts: billet extruding and cutting device, molding device, and billet transfer device, and all devices are fixed on the chassis 17, wherein

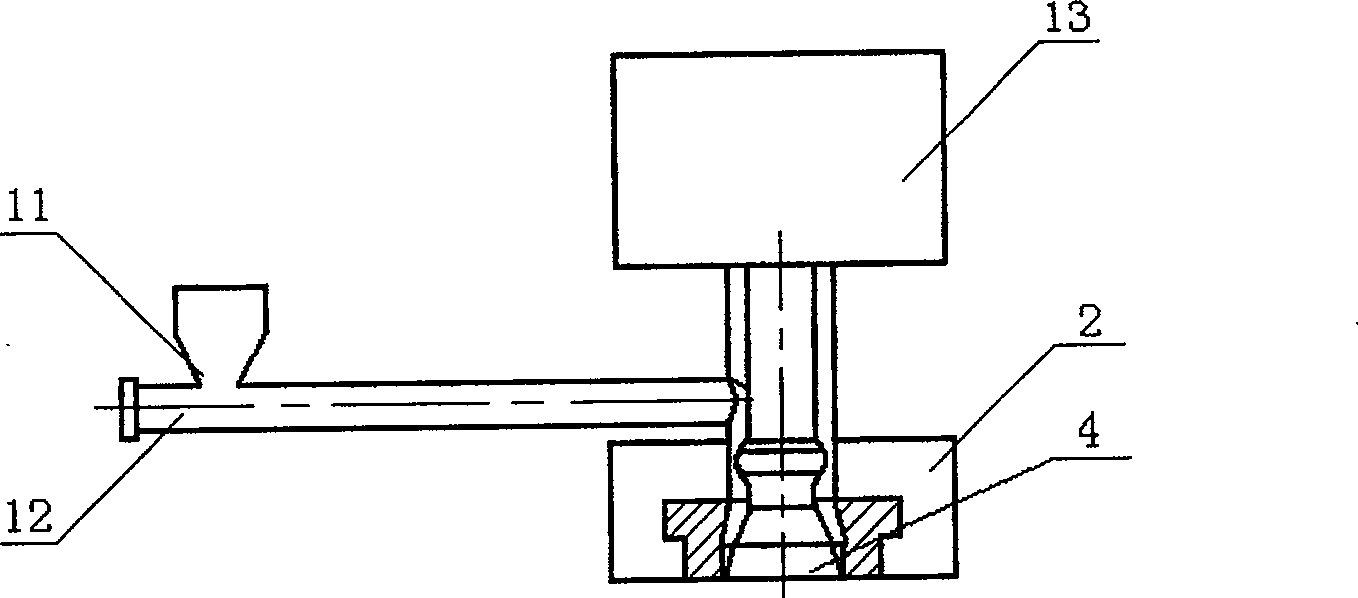

[0025] Billet extrusion and cutting device: composed of a hopper 11, an extruder 1, an extrusion die 2, and a cutting rod device 4, and is located at the left end of the entire molding equipment. The hopper 11 is a part of the extruder, the extrusion die 2 is fixed on the extruder 1, the cutting rod 4 is installed in the extrusion die 2, and the blank 3 is cut off by the up and down movement of the cutting rod 4.

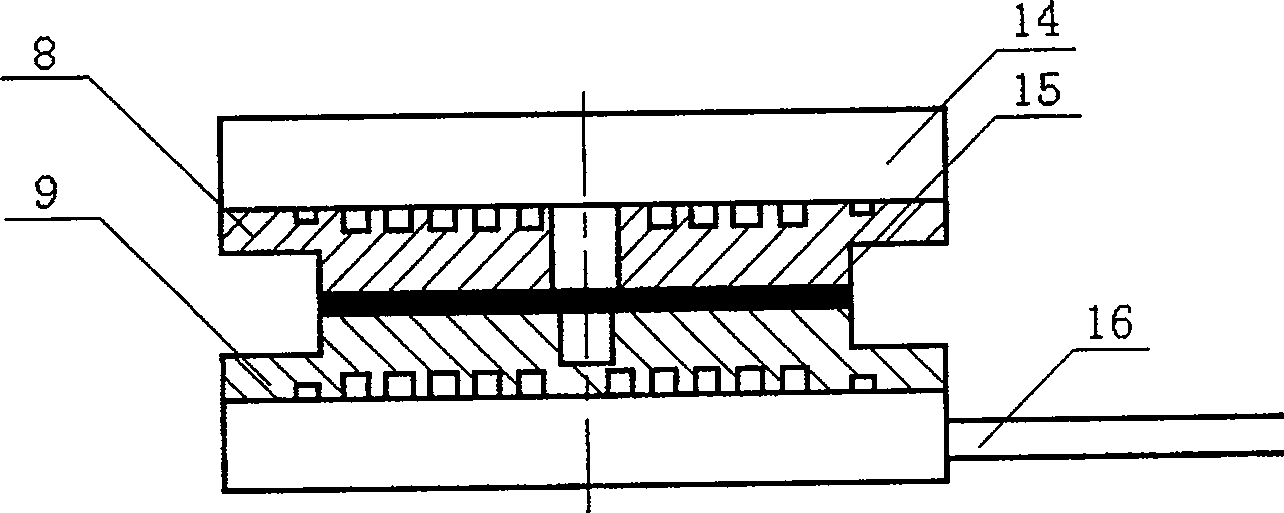

[0026] Molding device: It is composed of a stamping system 7, an upper mold 8 of a pressing mold, a lower mold 9 and a finished product warehouse 10, and is located in the middle of the entire molding equipment. The upper mold 8 is fixed on the stamping system 7, and the lower mold 9 is fixed on the end of the billet transfer device 5, and can reciprocate l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com