Traction driven shearing fork telescopic lifting mechanism

A technology of lifting mechanism and driving mechanism, applied in the direction of lifting frame, lifting device, etc., can solve the problems of endangering safety, large volume, complicated structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

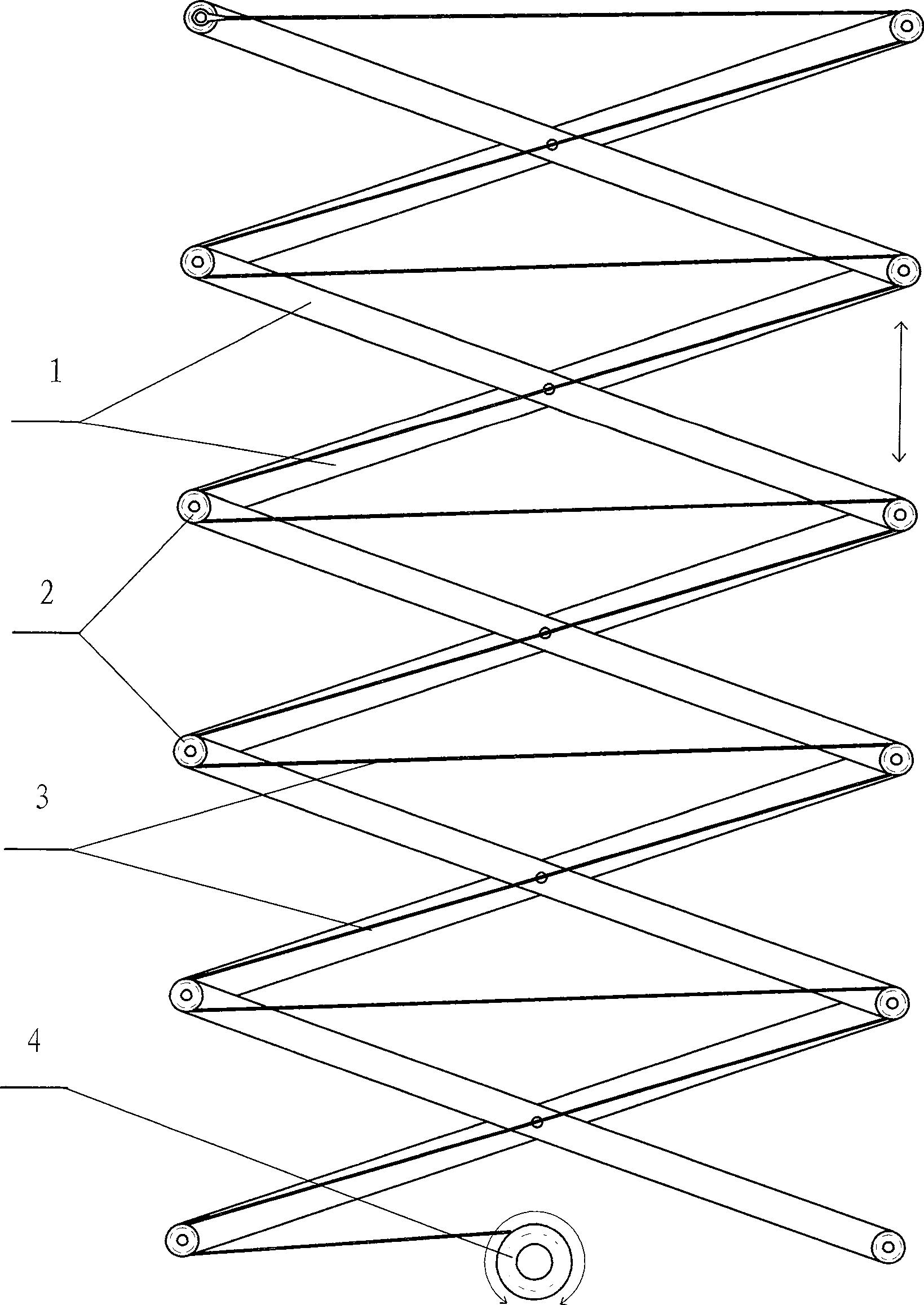

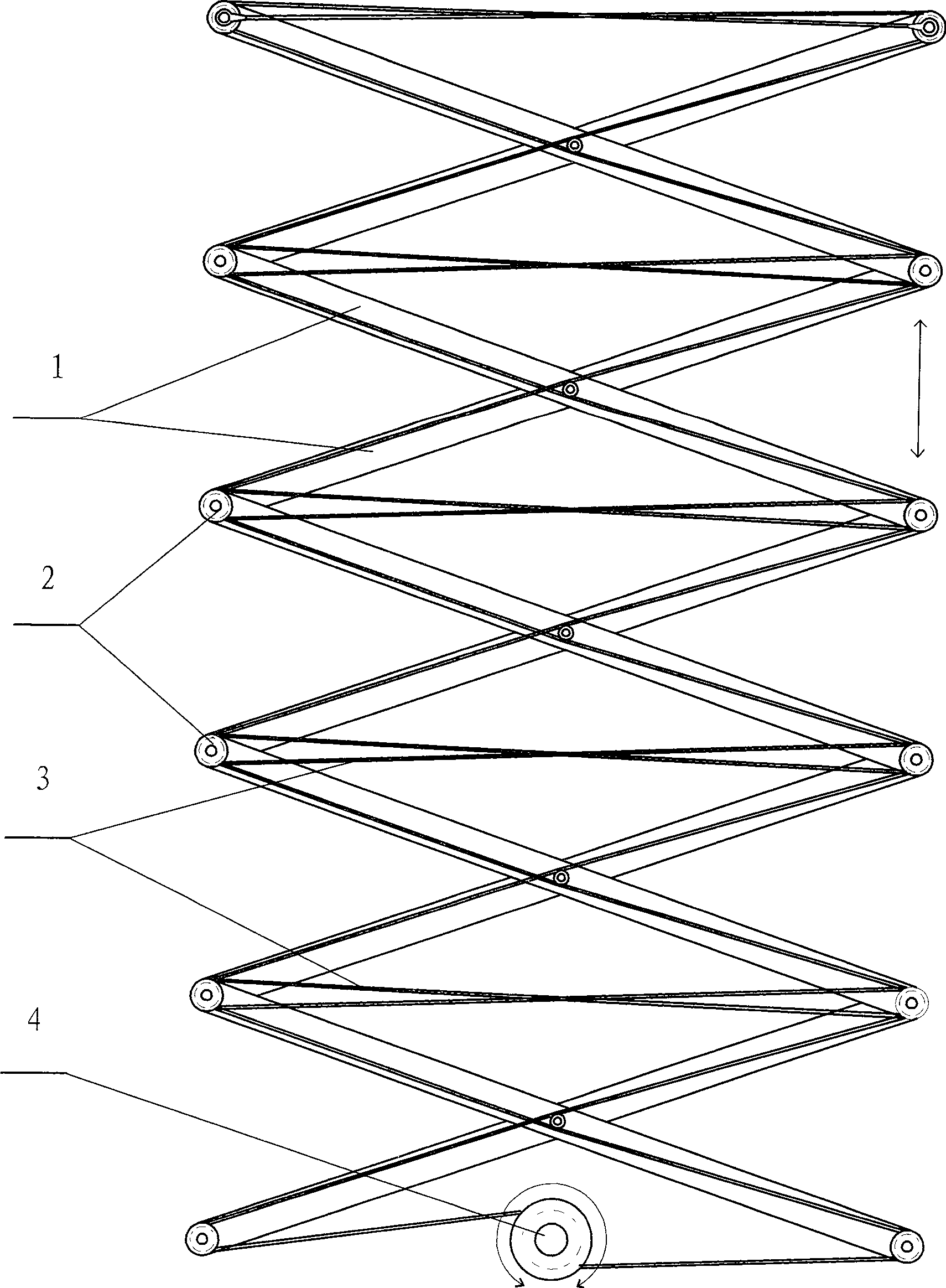

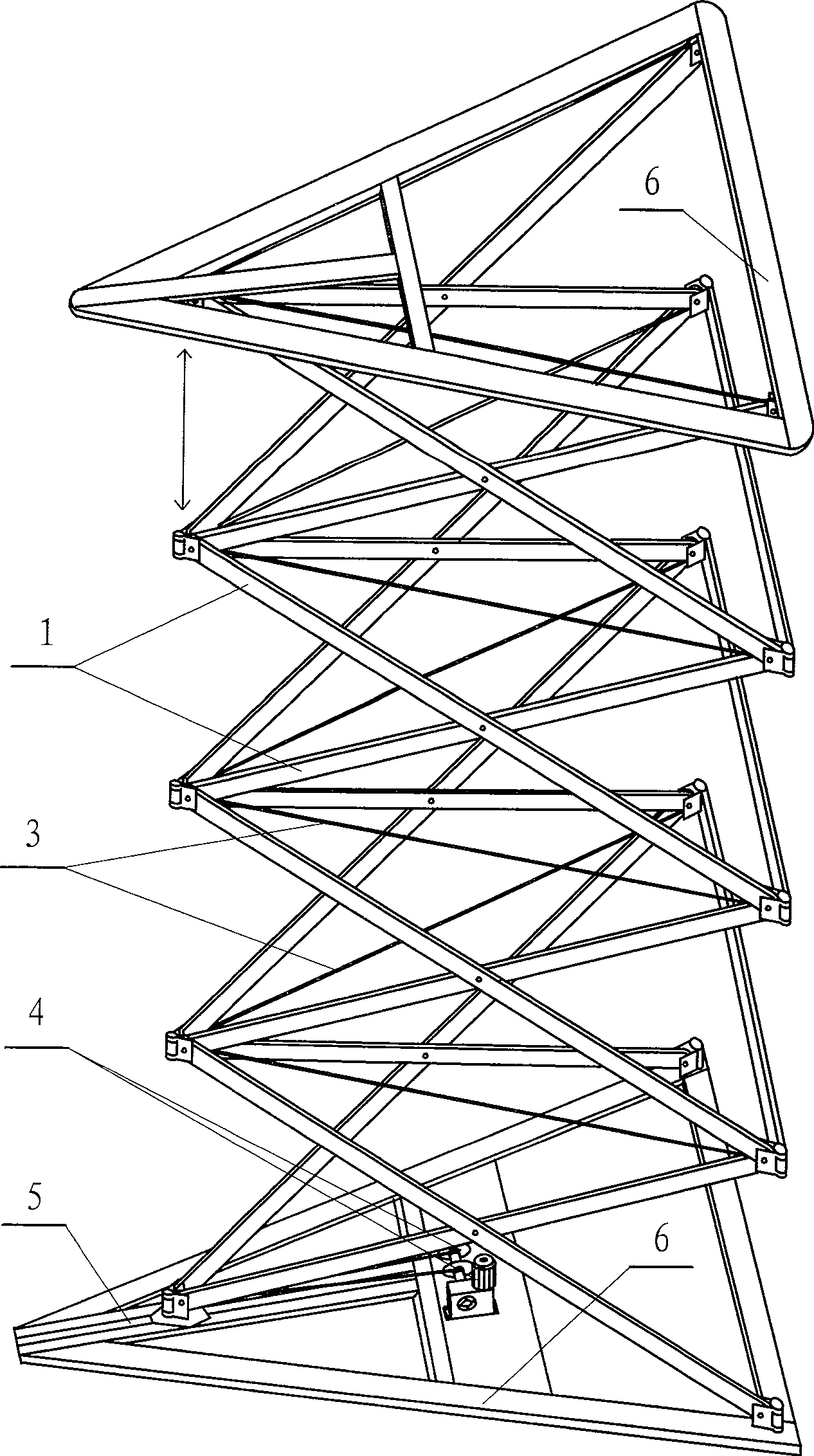

[0014] In a specific implementation, the traction-driven scissors telescopic lifting mechanism can be made into various types and styles, and applied to various telescopic lifting support mechanical equipment or operating fields. attached figure 1 It shows the principle of traction drive composed of a group of cables 3 and pulleys 2 in a scissor row. attached figure 2 It is a schematic illustration of the principle of pulling and driving with two sets of drag cables 3 and pulleys 2 in the same scissor row. In the schematic diagram of the pulling drive, the pulley 2 is arranged at each cross-linking node of the scissor bar 1 of the scissors row, and the pulley 3 is connected in series between the pulleys 2, and the pulling drive mechanism 4 drives and controls the pulling of the pulley 3. Tightening, release or static pulling, through the cable 3 and the pulley 2, the transmission force changes or the angle change of the limited scissor bar 1 drives the scissor mechanism to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com