A multi-functional automatic telescopic car

An automatic telescopic and automotive technology, which is applied in the direction of motor vehicles, vehicles used for freight, vehicles including people's living appliances, etc., can solve the problems of increasing volume, inconvenient driving, and increasing the space of the car body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

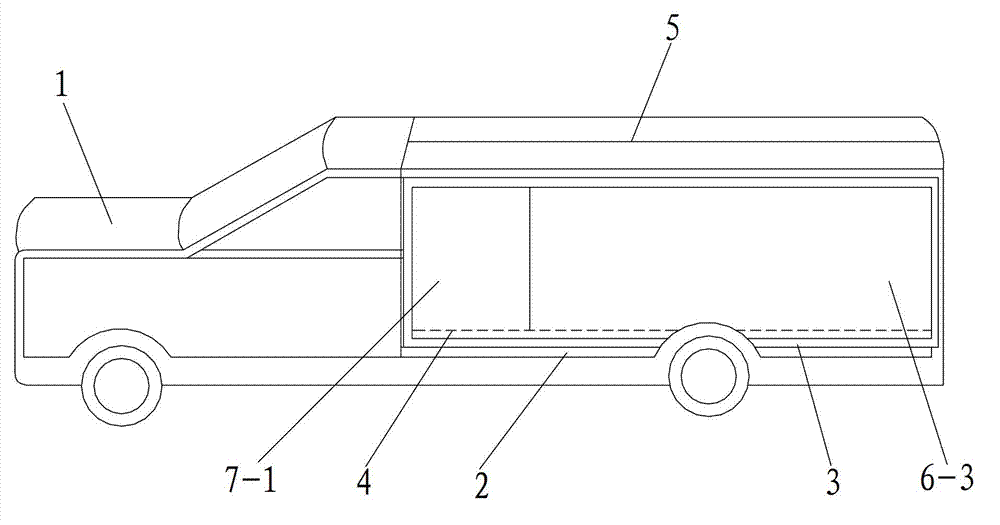

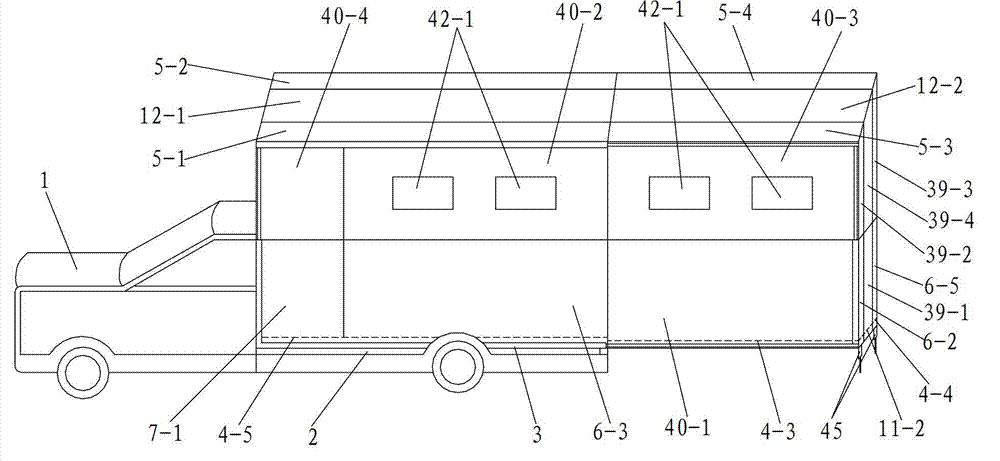

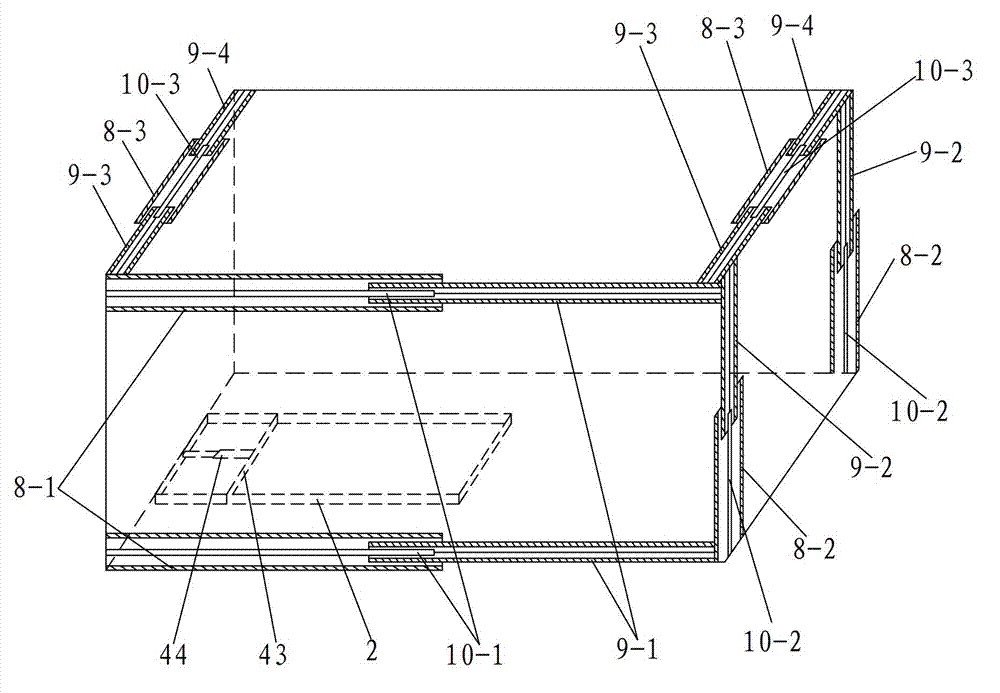

[0167] like figure 1 and figure 2 As shown, the present invention includes a vehicle body 1, a vehicle frame 2 and a compartment, the compartment is a telescopic compartment, and the telescopic compartment includes a telescopic compartment framework 3 connected to the vehicle frame 2, and a telescopic compartment framework 3 connected to the bottom of the telescopic compartment framework 3 The telescopic bottom frame 4, the telescopic top cover 5 connected to the top of the telescopic carriage frame 3 and the carriage walls connected around the telescopic carriage skeleton 3, and the telescopic carriage skeleton 3, the telescopic bottom frame 4 and the telescopic The top cover 5 is connected and used to drive the telescopic mechanism for the telescopic movement of the telescopic carriage frame 3, the telescopic bottom frame 4 and the telescopic top cover 5. The telescopic bottom frame 4 is provided with a bottom surface gap closing device, and the telescopic top A top cover ...

Embodiment 2

[0231] combine Image 6 The difference between this embodiment and Embodiment 1 is that the first hydraulic pump 18 is an electric hydraulic pump, and the first power system is an external AC power supply 27 or / and an alternator 28 installed in the vehicle body 1 , the output voltages of the external AC power supply 27 and the AC generator 28 are 380V, 220V or 110V, and the electric hydraulic pump is connected to the output terminal of the first controller 19 . All the other structures are the same as in Example 1.

[0232] This embodiment is equivalent to providing three specific implementation modes, the first one: assuming that it is convenient to use the external AC power supply 27 anytime and anywhere, without changing the automobile generator used on the automobile in the prior art, the first hydraulic pump 18 can only Adopt the external AC power supply 27 to supply power; the second type: do not reserve the external AC power supply 27 power supply interface, change the...

Embodiment 3

[0236] combine Figure 4 The difference between this embodiment and Embodiment 1 is that the telescopic carriage frame 3 also includes 6 second telescopic rods respectively correspondingly connected to the middle positions of the 6 surfaces of the cube frame, located on the vehicle frame 2 The two second telescopic rods in the length direction are both composed of a second length direction large sleeve 13-1 and a second length direction small sleeve 14-1 sleeved in the second length direction large sleeve 13-1, located at The two second telescopic rods in the height direction of the vehicle frame 2 are composed of a second height direction large sleeve 13-2 and a second height direction small sleeve 14 sleeved in the second height direction large sleeve 13-2. -2, the two second telescopic rods located in the width direction of the vehicle frame 2 are composed of the second width direction large sleeve 13-3 and the second width sleeve 13-3 sleeved in the second width direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com