Glass plate used for solar cell module packaging

A technology of solar cells and glass plates, applied in electrical components, circuits, photovoltaic power generation and other directions, to achieve the effect of saving cost and danger, good durability and high power added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

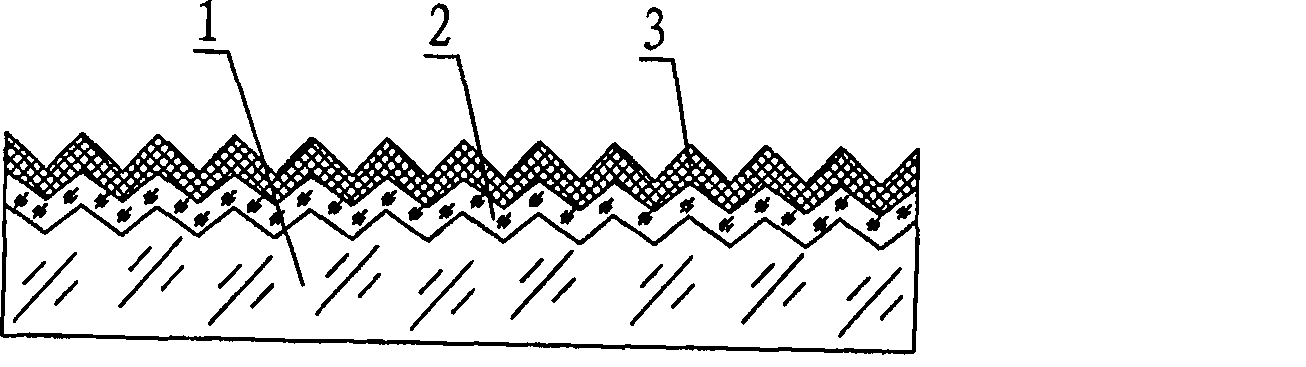

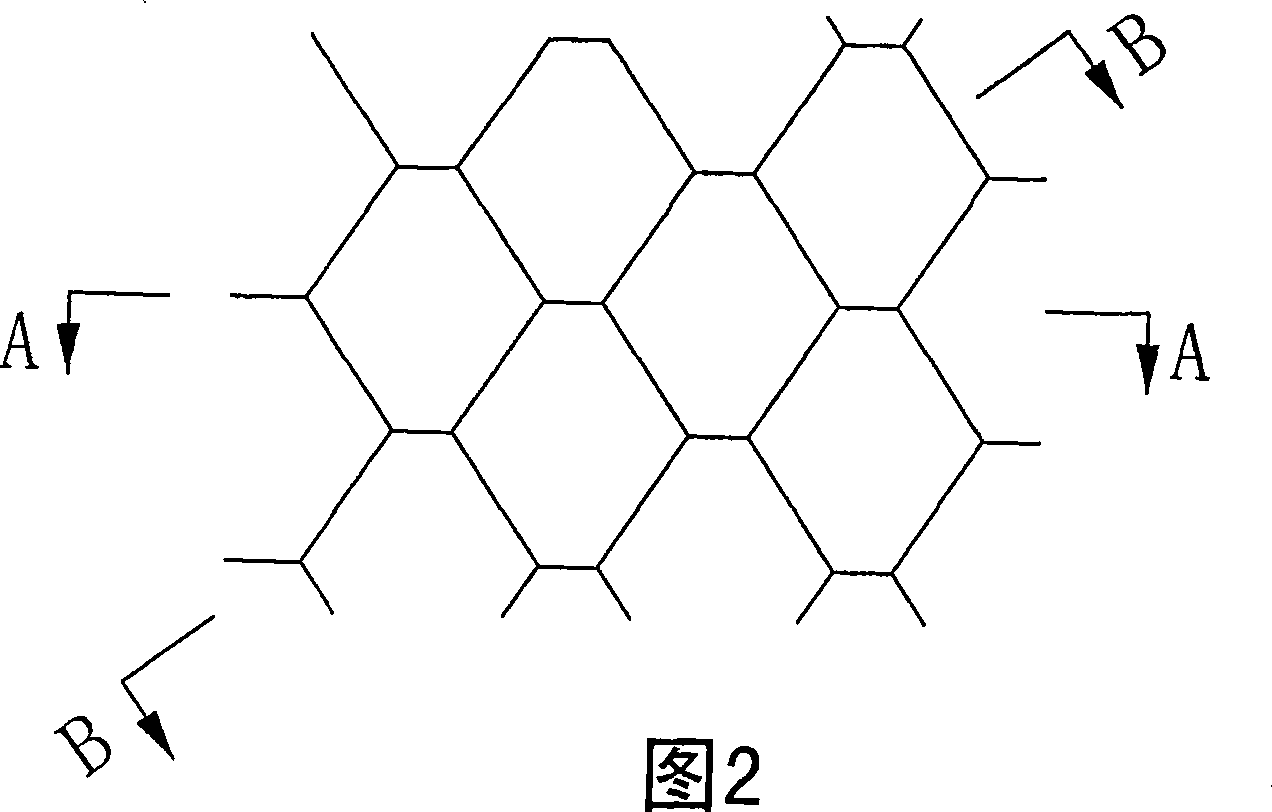

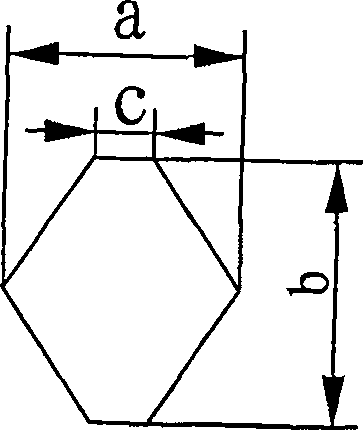

[0017] Such as Figure 1 to Figure 5 As shown, a glass plate for encapsulating solar cell modules includes a glass substrate 1 and a coating 3 coated on the glass substrate 1, one side of the glass substrate 1 is provided with an embossed layer 2 with a pattern, the glass The coating 3 above the substrate 1 is coated on the surface of the embossed layer 2, and the coating 3 is composed of zirconia and magnesium fluoride, and their weight percentages are 25% of zirconia, 75% of magnesium fluoride, and the coating 3 The thickness is 130nm. The pattern shape on the embossed layer 2 is honeycomb shape, and the arrangement of each honeycomb pattern is closely arranged, and the honeycomb opening is a deformed regular hexagon, that is, the lengths of the upper and lower opposite sides of the deformed regular hexagon are parallel and equal, but the same as The lengths of the remaining four sides are not equal, and the lengths of the remaining four sides are equal. In each honeycomb,...

Embodiment 2

[0019] Such as Figure 1 to Figure 5 As shown, a glass plate for encapsulating solar cell modules includes a glass substrate 1 and a coating 3 coated on the glass substrate 1, one side of the glass substrate 1 is provided with an embossed layer 2 with a pattern, the glass The coating 3 above the substrate 1 is coated on the surface of the embossed layer 2, and the coating 3 is composed of zirconia and magnesium fluoride, and their weight percentages are 38% of zirconia, 62% of magnesium fluoride, and the coating 3 The thickness is 145nm. The pattern shape on the embossed layer 2 is honeycomb shape, and the arrangement of each honeycomb pattern is closely arranged, and the honeycomb opening is a deformed regular hexagon, that is, the lengths of the upper and lower opposite sides of the deformed regular hexagon are parallel and equal, but the same as The lengths of the remaining four sides are not equal, and the lengths of the remaining four sides are equal. In each honeycomb,...

Embodiment 3

[0021] Such as Figure 1 to Figure 5 As shown, a glass plate for encapsulating solar cell modules includes a glass substrate 1 and a coating 3 coated on the glass substrate 1, one side of the glass substrate 1 is provided with an embossed layer 2 with a pattern, the glass The coating 3 above the substrate 1 is coated on the surface of the embossed layer 2, and the coating 3 is composed of zirconia and magnesium fluoride, and their weight percentages are 30% of zirconia, 70% of magnesium fluoride, and the coating 3 The thickness is 135nm. The pattern on the embossed layer 2 is honeycomb-shaped, and the arrangement of each honeycomb pattern is closely arranged, and the honeycomb mouth is a deformed regular hexagon, that is, the lengths of the upper and lower opposite sides of the deformed regular hexagon are parallel and equal. The lengths of the remaining four sides are not equal, and the lengths of the remaining four sides are equal. In each honeycomb, the depth d of the hon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com