Core-shooting device, core-shooting method and core-shooting controlled system

A technology for controlling valves and vacuum systems, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., and can solve problems such as core sand cannot reach, sand core compactness is not enough, and injection is not solid, so as to ensure the compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0054] One of the core ideas of the embodiment of the present invention is that by adding a vacuum system to the original core shooter, the gas is continuously pumped out through the vacuum system, and there is no air pressure accumulation in any part of the core box, so that the air pressure remains constant, thus ensuring The tightness of each part of the sand core.

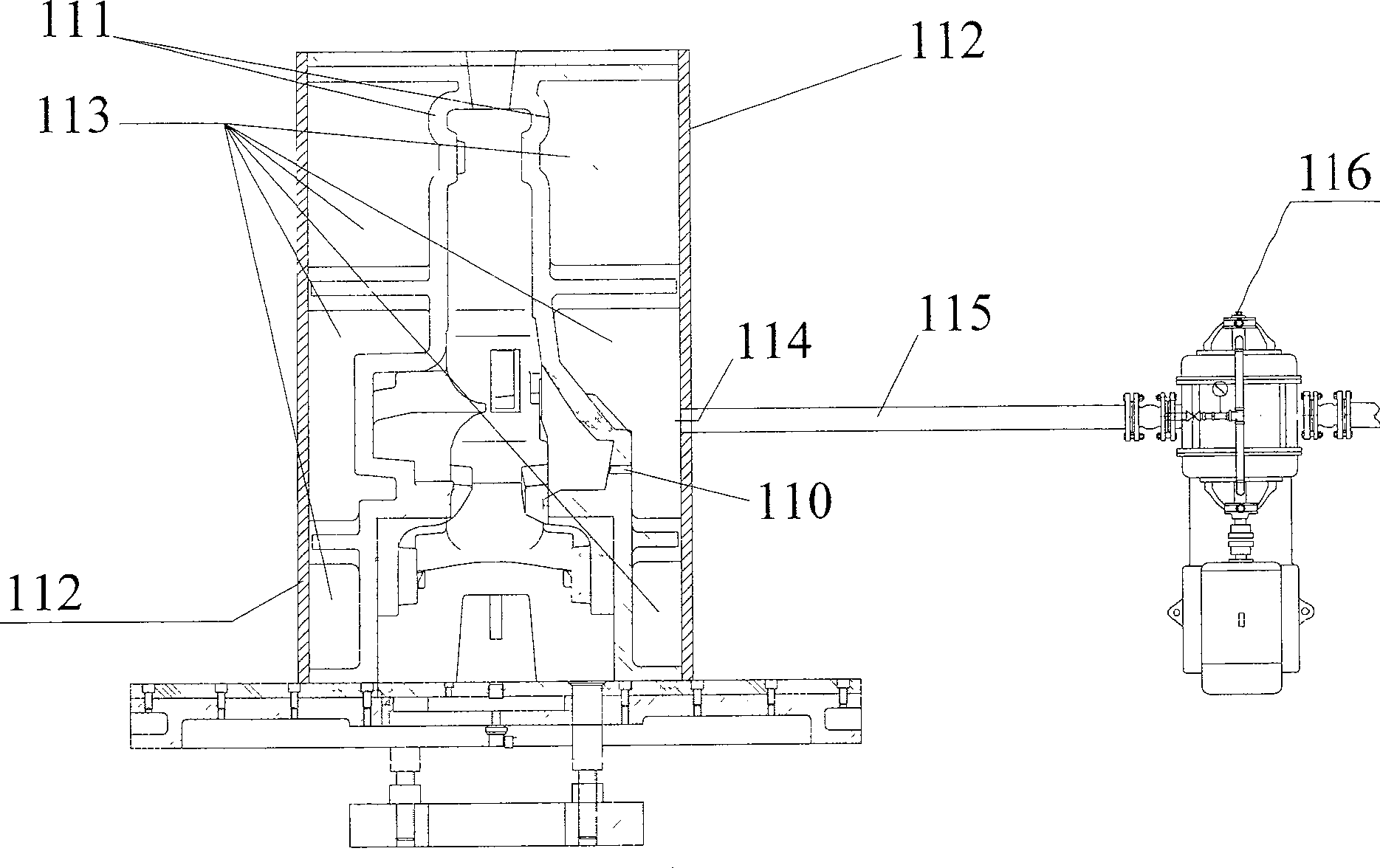

[0055] refer to figure 1 , which shows a schematic structural view of Embodiment 1 of a core shooting device of the present invention, specifically including the following components:

[0056] a core box 111 with ventilation means 110;

[0057] A sealing plate 112 covering the outer surface of the core box 111, a cavity 113 is provided between the sealing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com