Tunnel type single-column cargo piling machine

A single-column, tunnel-type technology, applied in the direction of lifting devices, etc., can solve the problems of inappropriate handling of light goods, high material consumption, high price and other problems, and achieve the effects of reliable performance, high operation efficiency and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

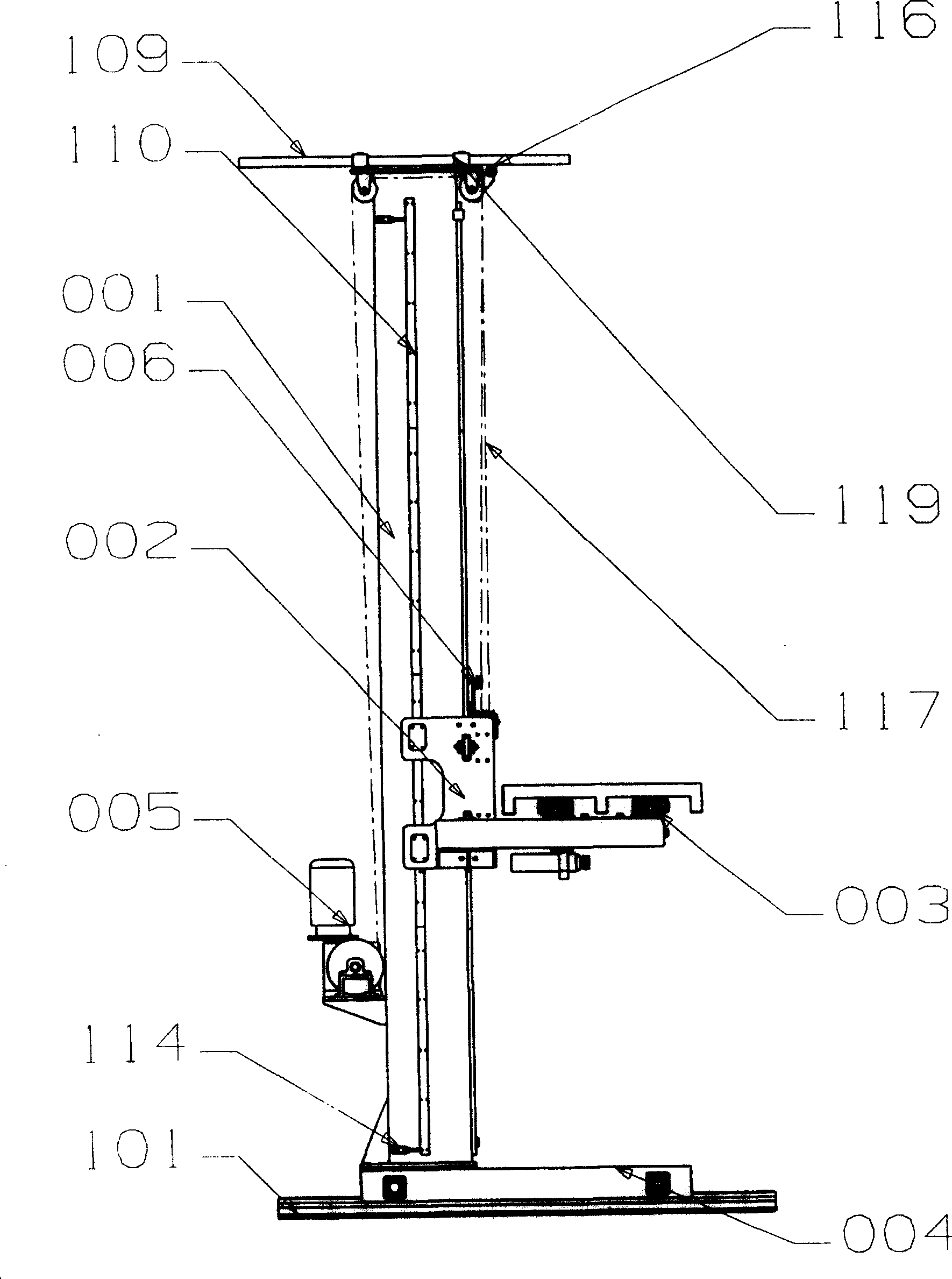

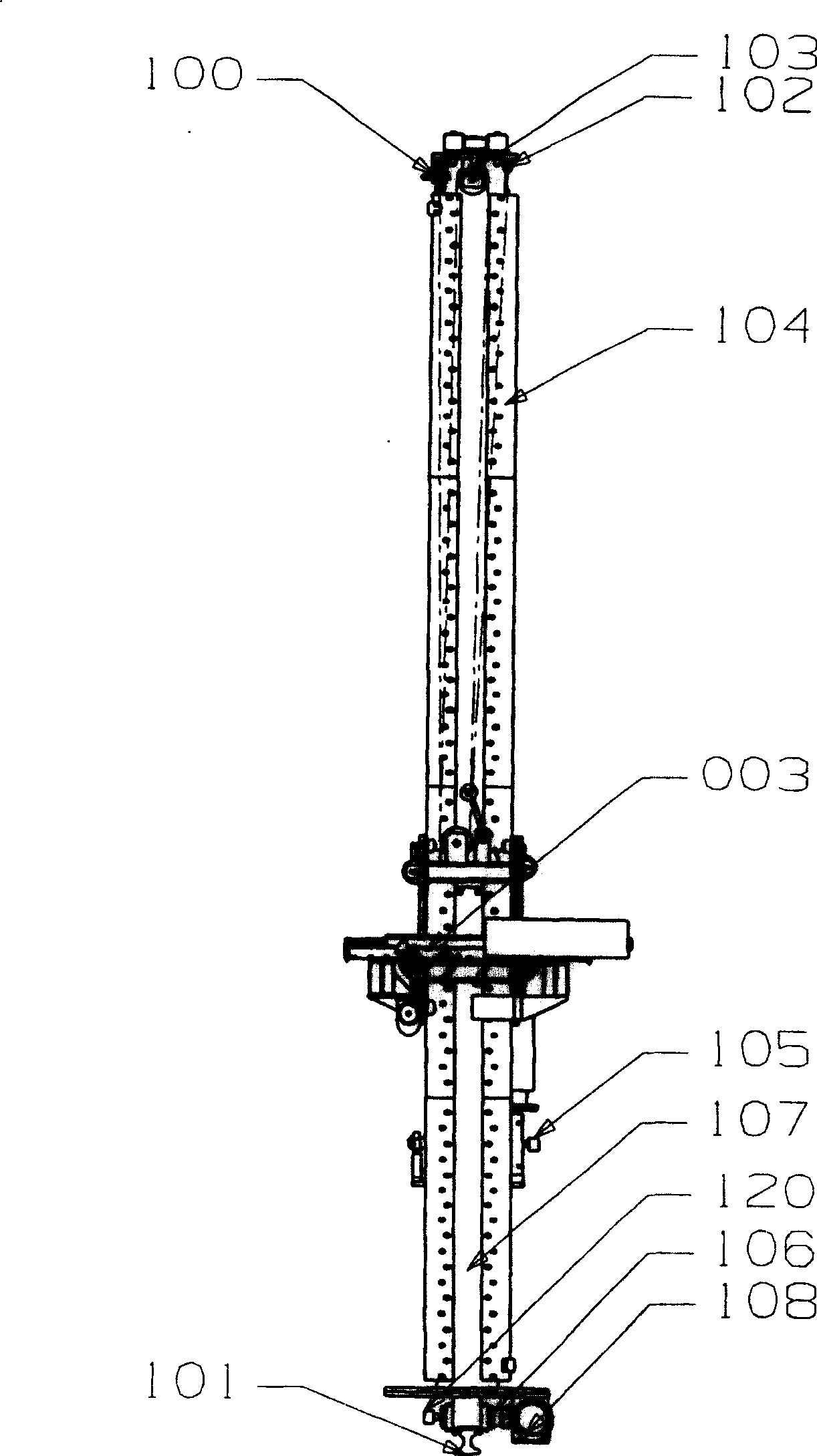

[0020] from figure 1 , figure 2 It can be clearly seen that the roadway type single-column cargo stacker consists of an upper rail 109, a lower rail 101, a stacker frame 001, a stacker elevator 002, a cargo fork pick-up device 003, a stacker walking device 004, an elevator drive mechanism 005 and The broken rope protection mechanism is composed of 006. Stacker frame 001 is made up of main column 107, stacking elevator 002 track 104, elevator auxiliary side guide wheel track 110, elevator driving mechanism 005, pulley block 103, guide pulley block 100, upper guide wheel block 119, and limit wheel 116.

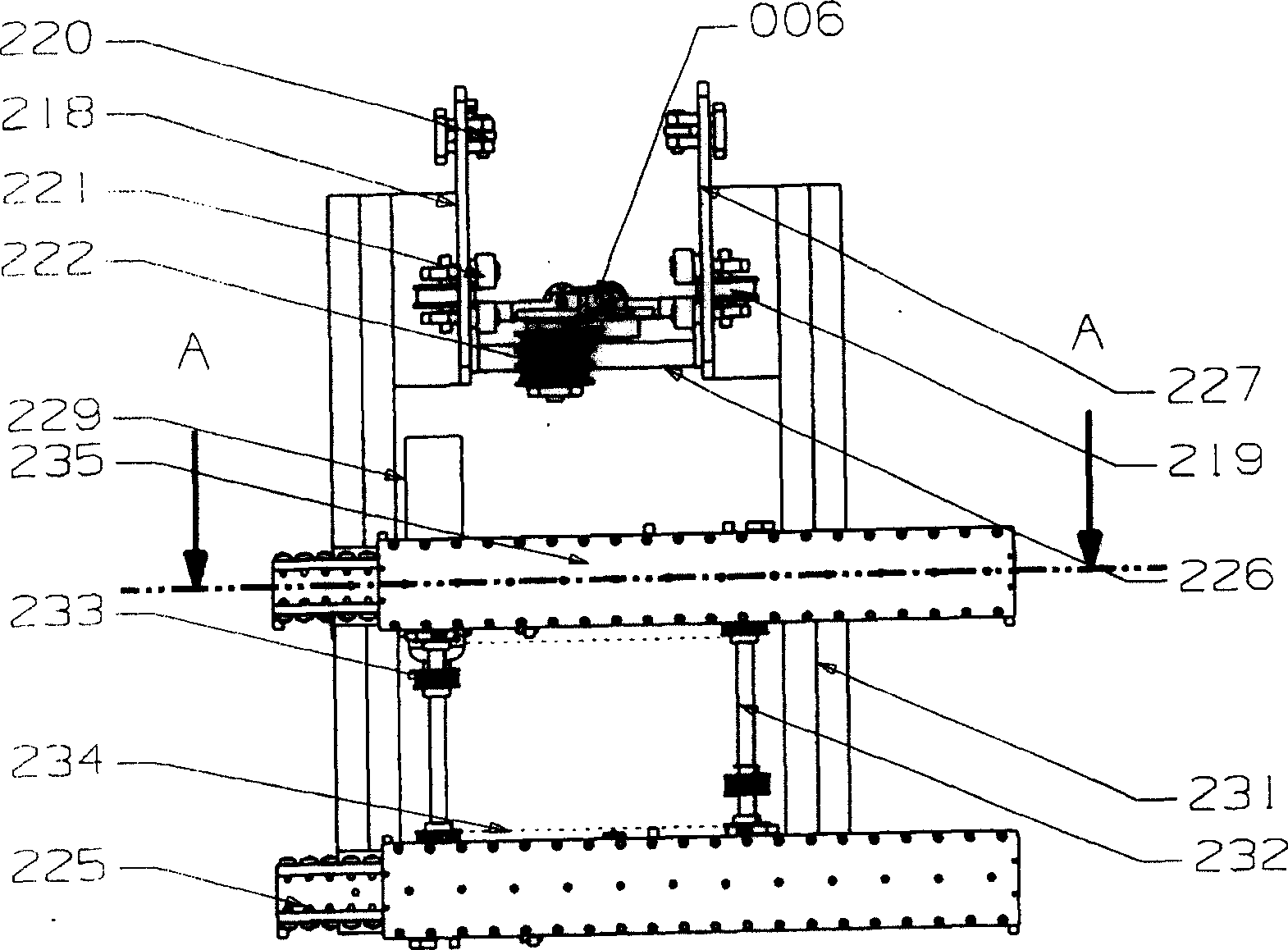

[0021] from image 3 , Figure 4 It can be clearly seen that the main frame of the stacker lift 002 is a three-dimensional frame structure, which is formed by connecting the left panel 218, the right panel 227, the frame saddle 226, the cargo fork-taking device chassis 225, etc. with bolts. The left panel 218 and the right panel 227 of the elevator are assembled and welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com