Mobile phone camera module group lens splicing board assembling method

The technology of a camera module and assembly method is applied in the direction of installation, telephone structure, printed circuit connected with non-printed electrical components, etc., which can solve the problems of increased production cost, reduced product service life, light leakage and oxidation, etc., to achieve The effect of reducing production costs, increasing production capacity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The process method of jigsaw assembly lens includes:

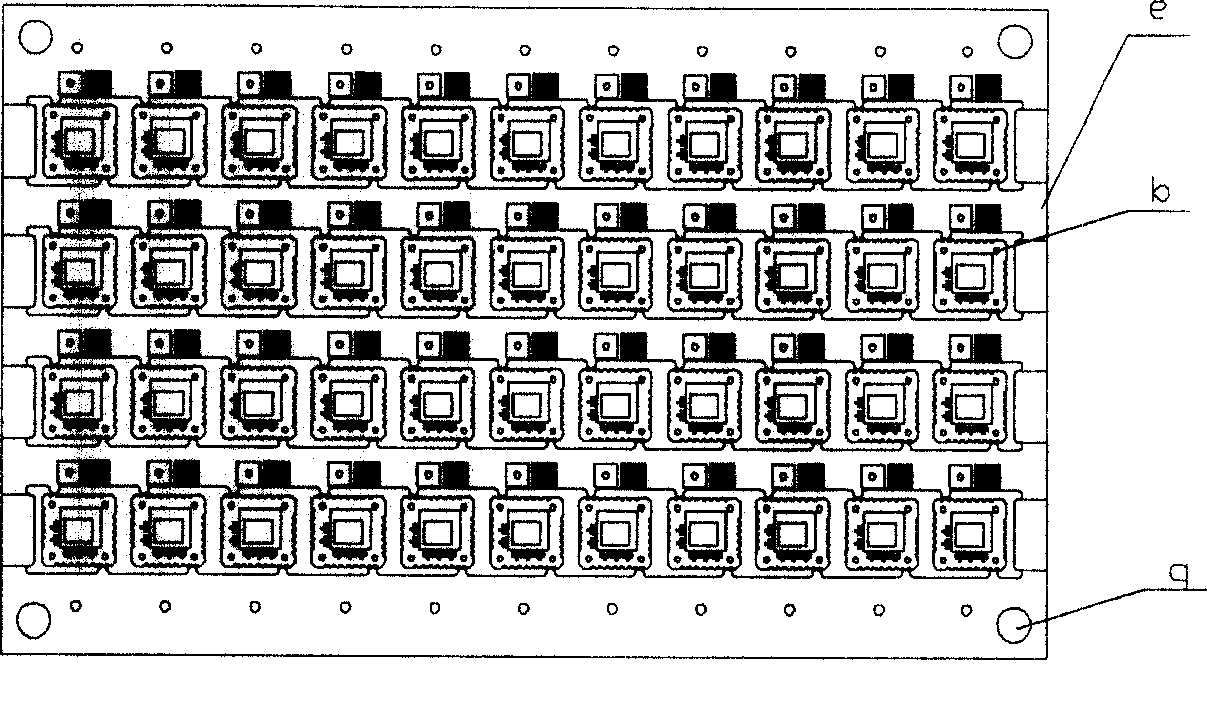

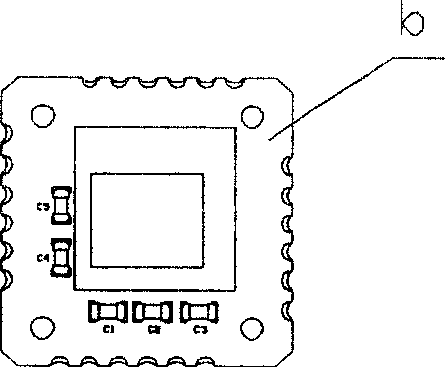

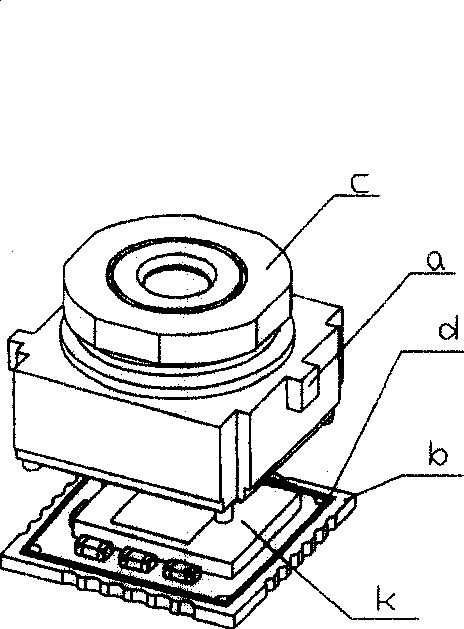

[0025] 1. Fixing the jigs and jigs of the jigsaw: install the jigs of the jigsaw e on the X axis of the automatic dispensing machine, and correct the X and Y axes of the jig to make it straight, because 1. Automatic glue dispensing The X-axis and Y-axis of the machine run straight along the track. If the fixture is installed tilted, it will cause the dispensing position and cause product failure. 2. The distance between the needle on the Z-axis of the automatic dispensing machine and the printed circuit board b It must be within a certain range, otherwise there will be uneven glue application, or even glue d, so add a jig including a gland j and a base h on the puzzle e to keep the puzzle e horizontal ( Attached Figure 6 ).

[0026] 2. Glue mixing: Glue (d) is a mixed glue containing glue A and glue B, wherein the mass ratio of glue A to glue B is 2.2~2.7. After mixing thoroughly, let it stand for 20~30 minutes; the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com