Aluminum alloy plate and process for producing the same

A technology for an aluminum alloy plate and a manufacturing method, which is applied to the aluminum alloy plate and the manufacturing field thereof, can solve the problems of high Mg content, insufficient solidification rate, difficulty in the balance of strength and ductility, and achieve the effect of improving the balance of strength and ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

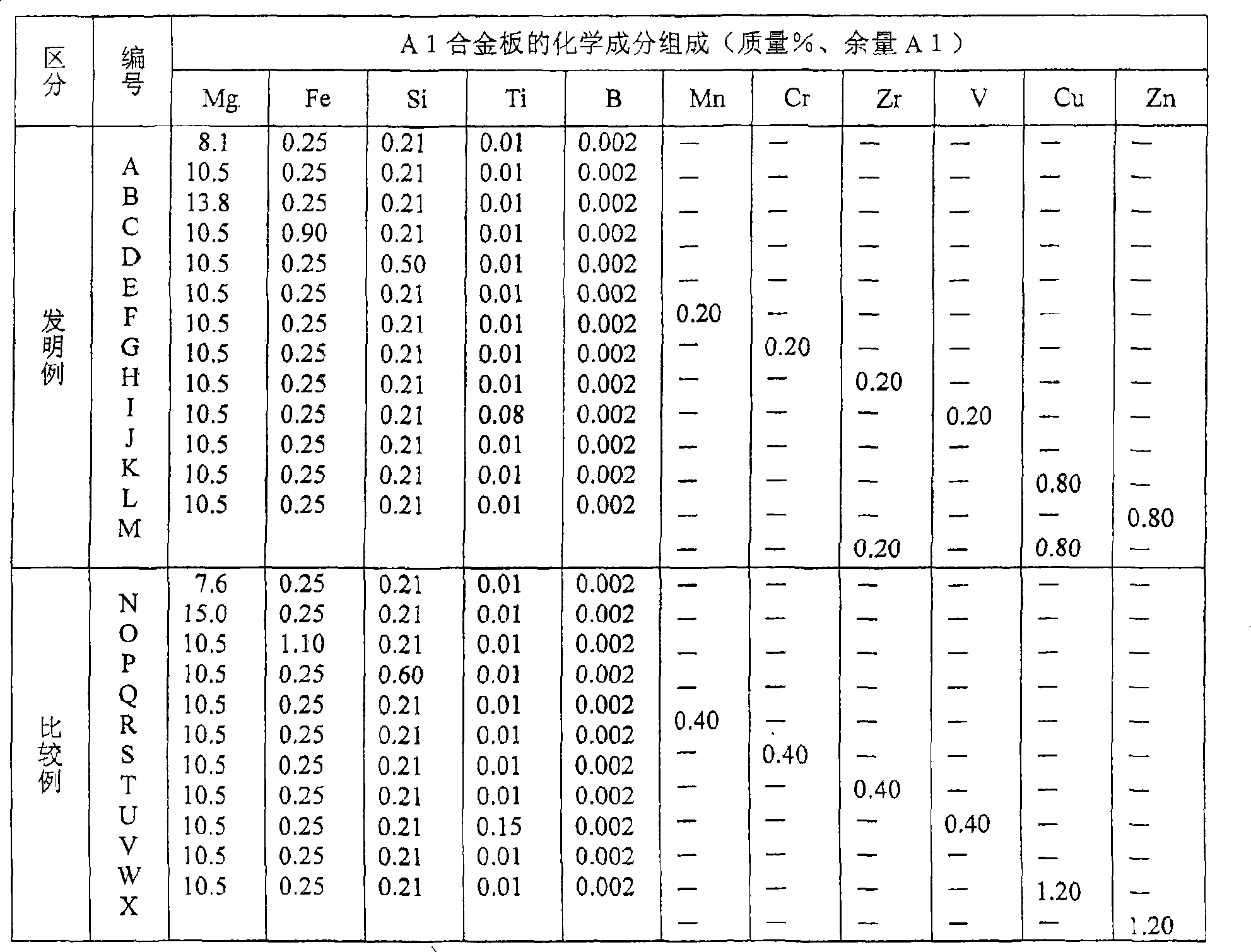

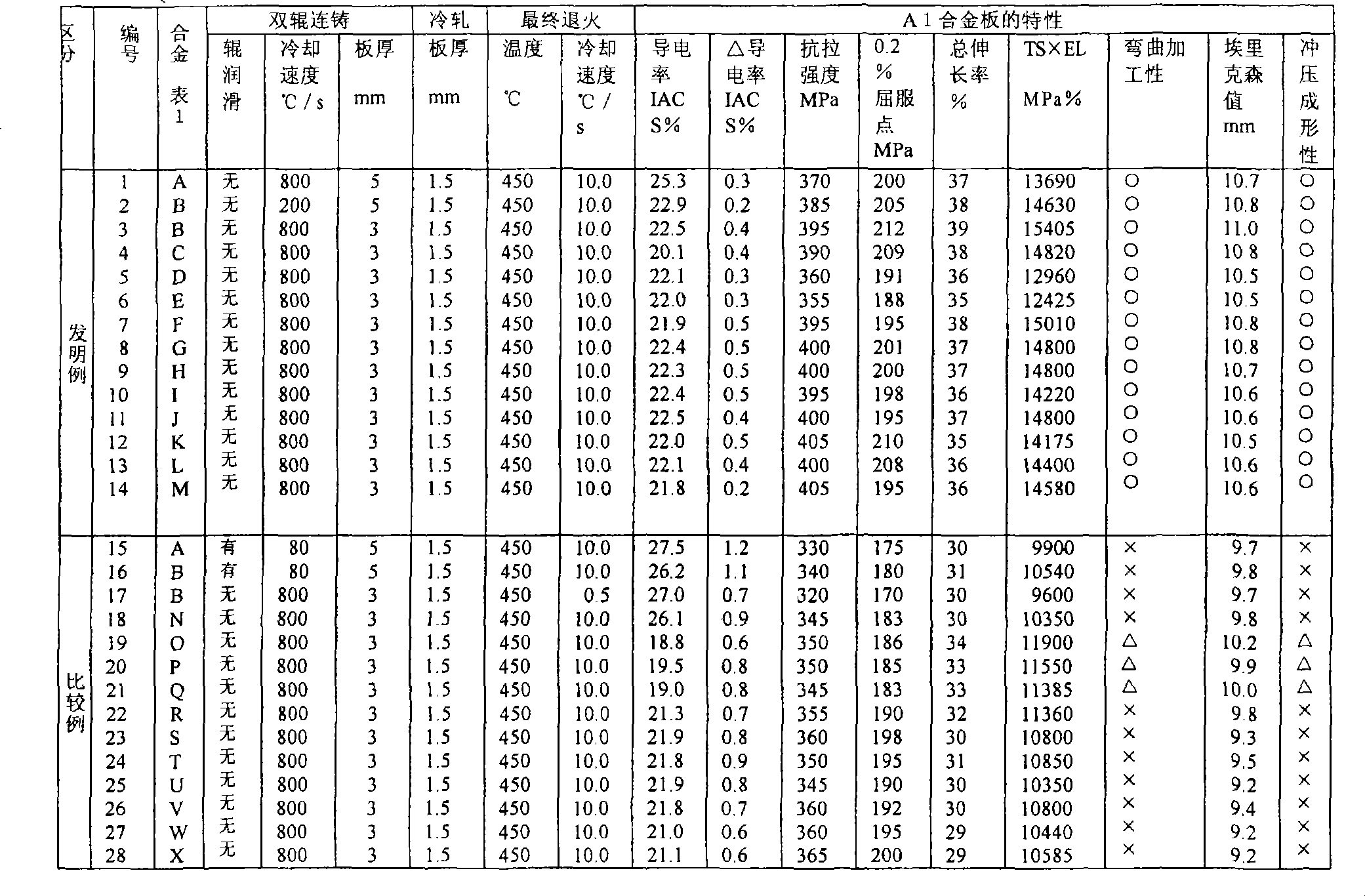

[0104] Next, Embodiment 1 of the present invention will be described. Al-Mg-based Al alloy melts (inventive examples A to M and comparative examples N to X) with various chemical composition compositions shown in Table 1 were cast into each of Plate thickness (3 ~ 5mm). Furthermore, these Al alloy cast thin plates were cold-rolled to a plate thickness of 1.5 mm. In addition, each of these cold-rolled sheets was subjected to final annealing and cooling in a continuous annealing furnace under the conditions shown in Table 2. The average grain size on the surface of the Al alloy sheets obtained in these inventive examples and comparative examples was all in the range of 30 to 60 μm.

[0105] Here, the rotational speed of the twin rolls during twin roll continuous casting was 70 m / min, and the pouring temperature when pouring the Al alloy melt onto the twin rolls was the liquidus temperature + 20°C, which were constant in each case. Lubrication of the surface of the twin rolls ...

Embodiment 2

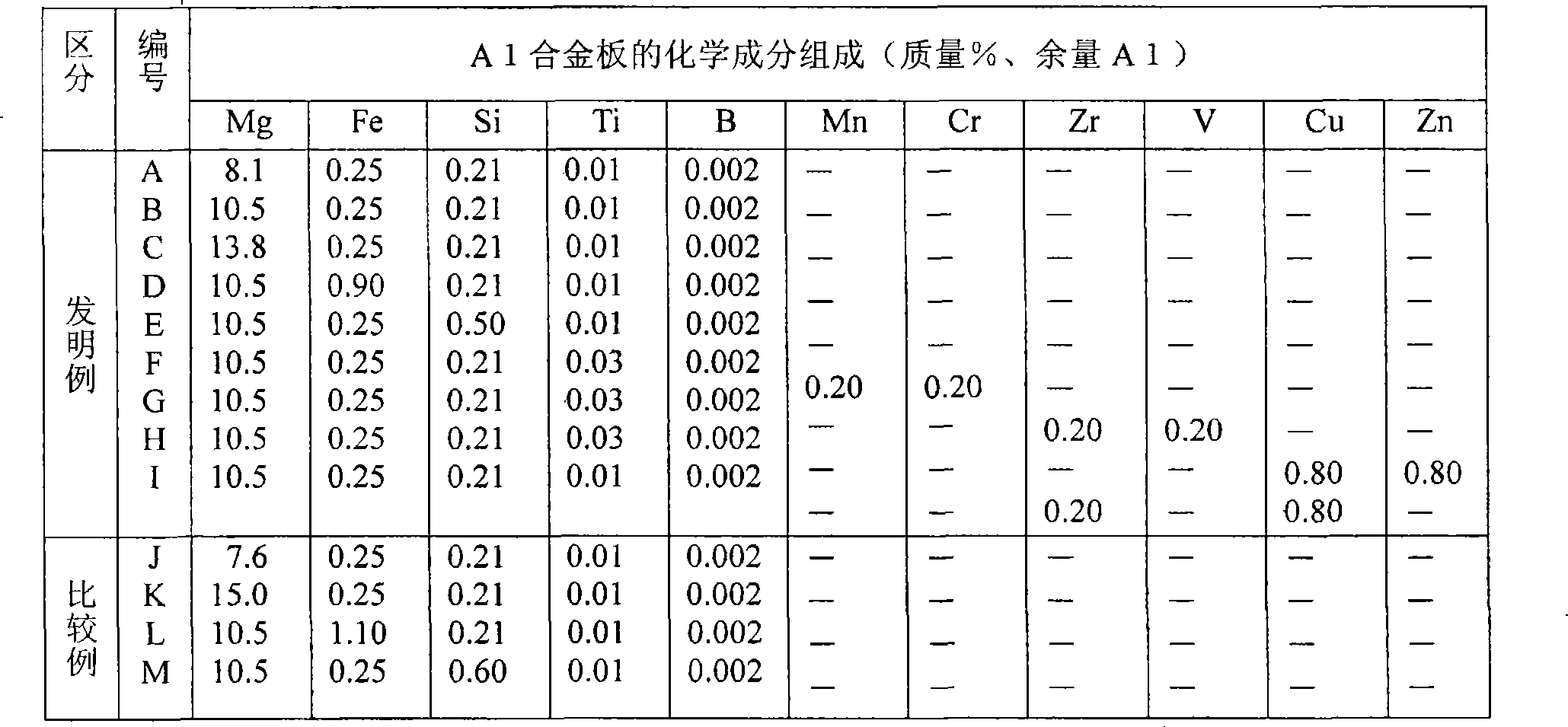

[0137] Next, Embodiment 2 of the present invention will be described. The various chemical compositions shown in Table 1 are composed of Al-Mg alloy melts (invention examples A~I, comparative examples J~M), which are cast into plate-shaped ingots (each plate thickness : 3 ~ 5mm). Furthermore, cold-rolled sheets (each sheet thickness: 1.5 mm) were produced from each plate-shaped ingot (Al alloy cast sheet) by the type of casting method shown in Table 2 under the specific process conditions shown in Table 3. Except for Comparative Example 13, the average crystal grain size on the surface of the Al alloy sheets obtained in these Invention Examples and Comparative Examples was in the range of 30 to 60 μm.

[0138] Here, the rotational speed of the twin rolls during twin roll continuous casting was 70 m / min, and the pouring temperature when pouring the Al alloy melt onto the twin rolls was the liquidus temperature + 20°C, which were constant in each example. Lubrication of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com