Building plastering mechanical hand

A manipulator and construction technology, applied in construction, building structure and other directions, can solve the problems of low plastering quality of walls and ceilings, high labor intensity, and more floor mortar, etc., achieve vertical plastering, reduce labor intensity, and solve the The effect of falling to the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

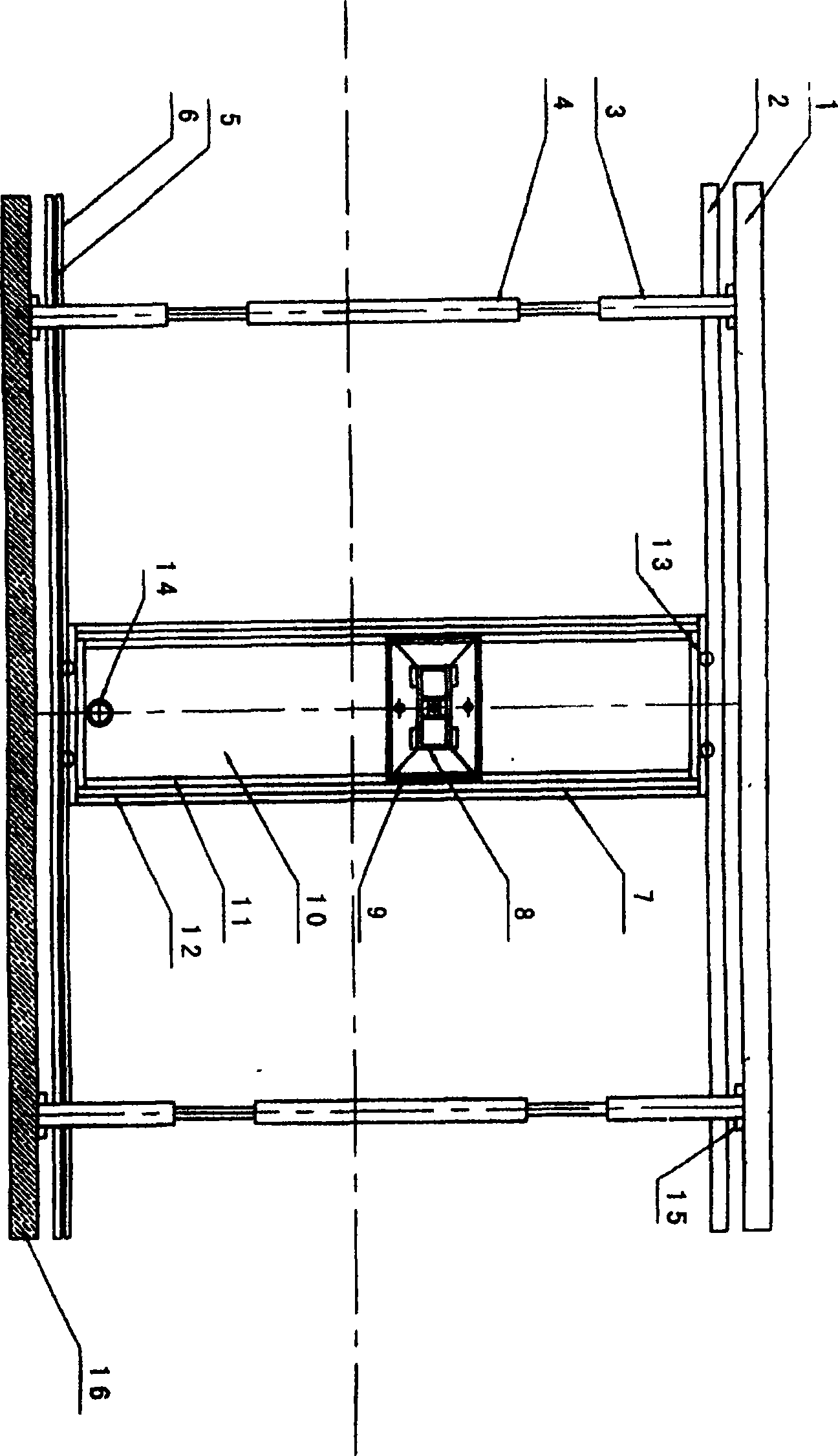

[0060] The specific embodiments of the present invention will now be described in conjunction with the accompanying drawings of the present invention.

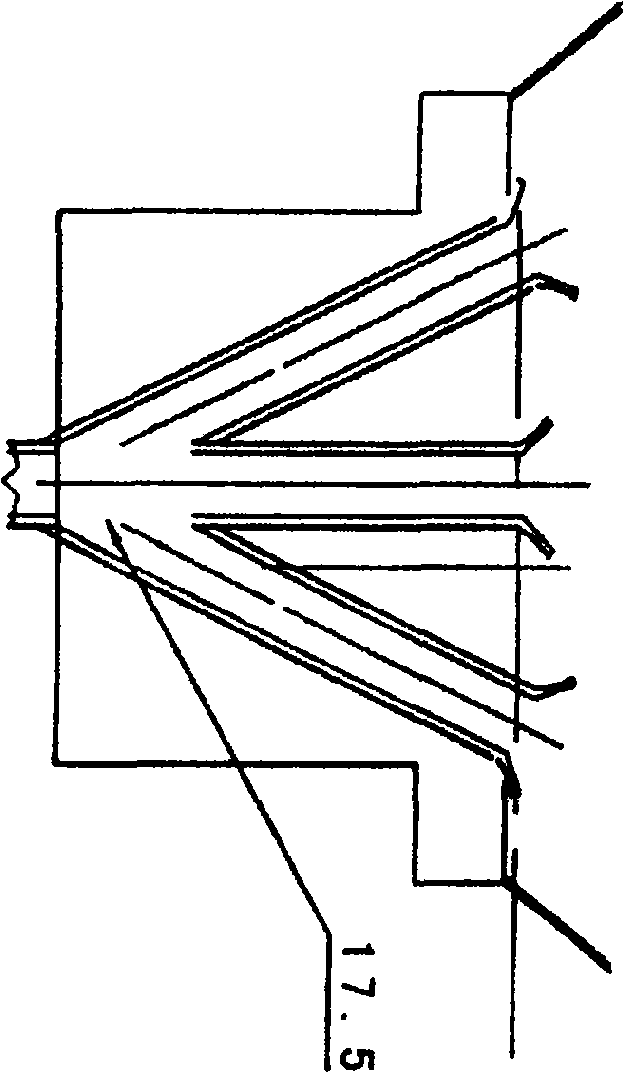

[0061] Such as figure 1 As shown, the construction plastering manipulator of the present invention includes: an upper support track 2 on the grid under the roof 1 and a lower support track 6 on the grid above the ground. The hydraulic lifting vertical column 3 stands on the ground 16, and the hydraulic lifting vertical column 3 is equipped with a lifting adjustment section 4 that can adjust its own height. The wiper rack 10 can walk in the horizontal direction between the wiper rack walking track 5 and the wiper rack wheel 13 through the motor 14. The wiper rack 9 and the wiper chamber 8 inside it The transmission chain 11 of the known transmission mode can slide on the lifting column 7. The fine-tuning gimbal 15 can fine-tune the vertical heights of the upper support rail 2 and the lower support rail 6 of the net frame. The moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com