Forging press workpiece-deficient detecting method

A detection method and technology for forging presses, applied in forging presses, forging presses, forging/pressing/hammer devices, etc., can solve the problems of not really reflecting the actual state of the stamping station, failure of photoelectric sensors, excessive dust, etc., to avoid leakage Phenomenon reporting, significant creativity, and accurate detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

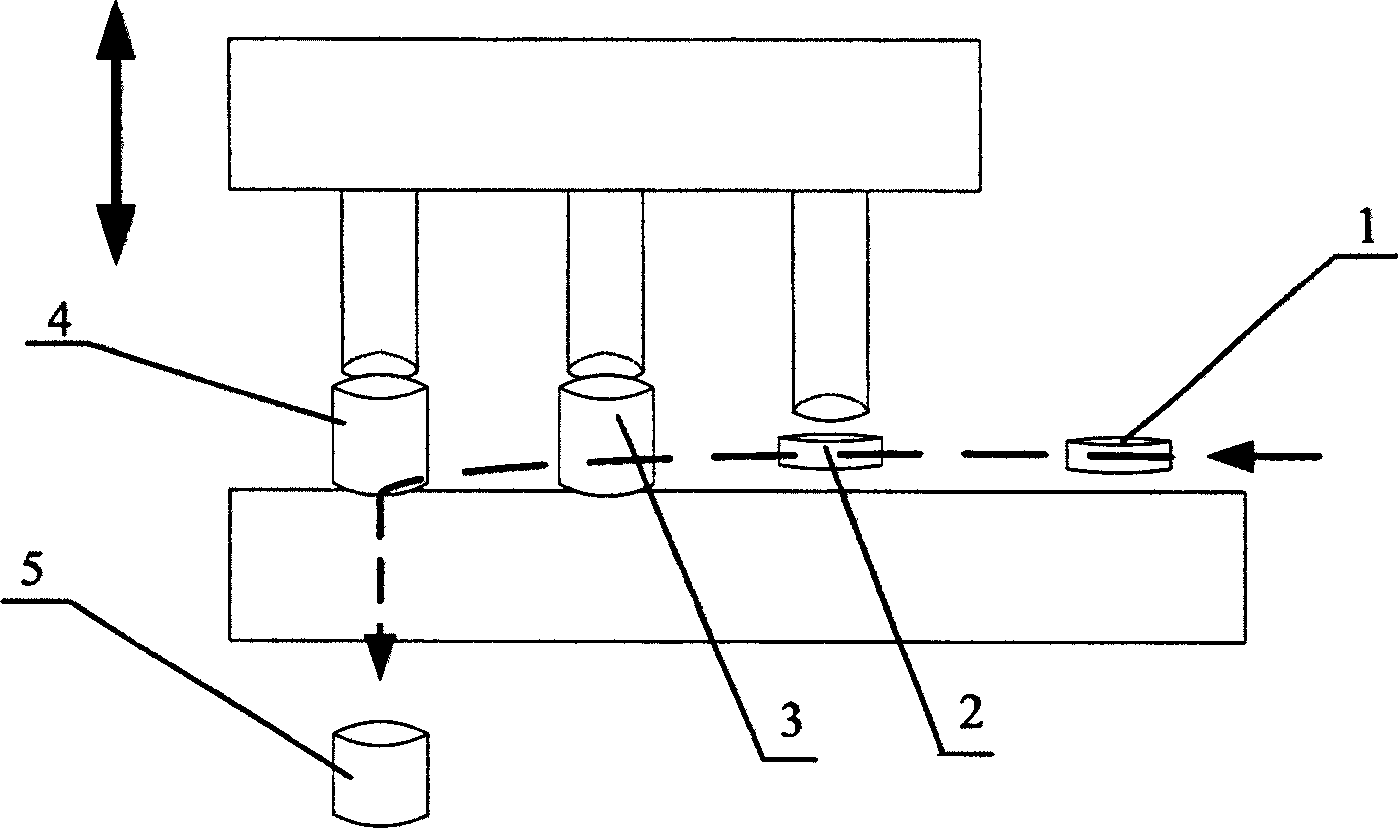

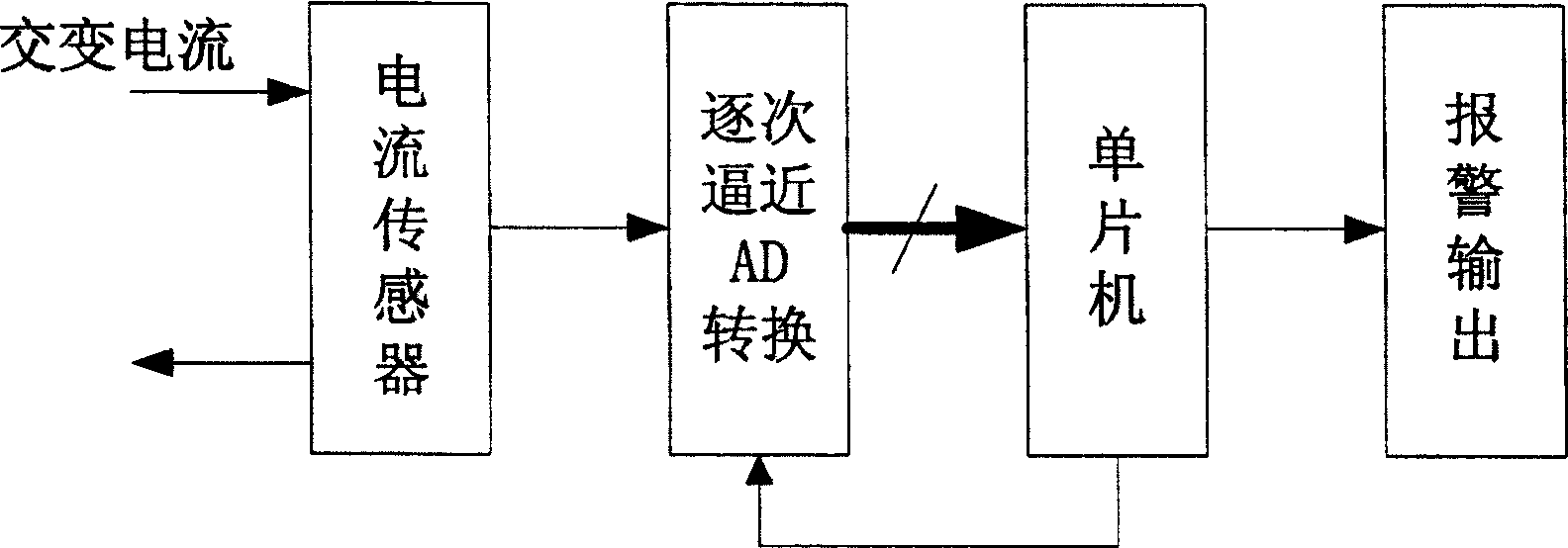

[0023] Example 1: see attached figure 1 to the attached Figure 4 As shown in the figure, a method for detecting missing parts of a forging press is used for the detection of the processing and forming of an aluminum casing of a cylindrical electrolytic capacitor, and the situation of missing parts is judged by detecting the working current of the forging press, including the following steps:

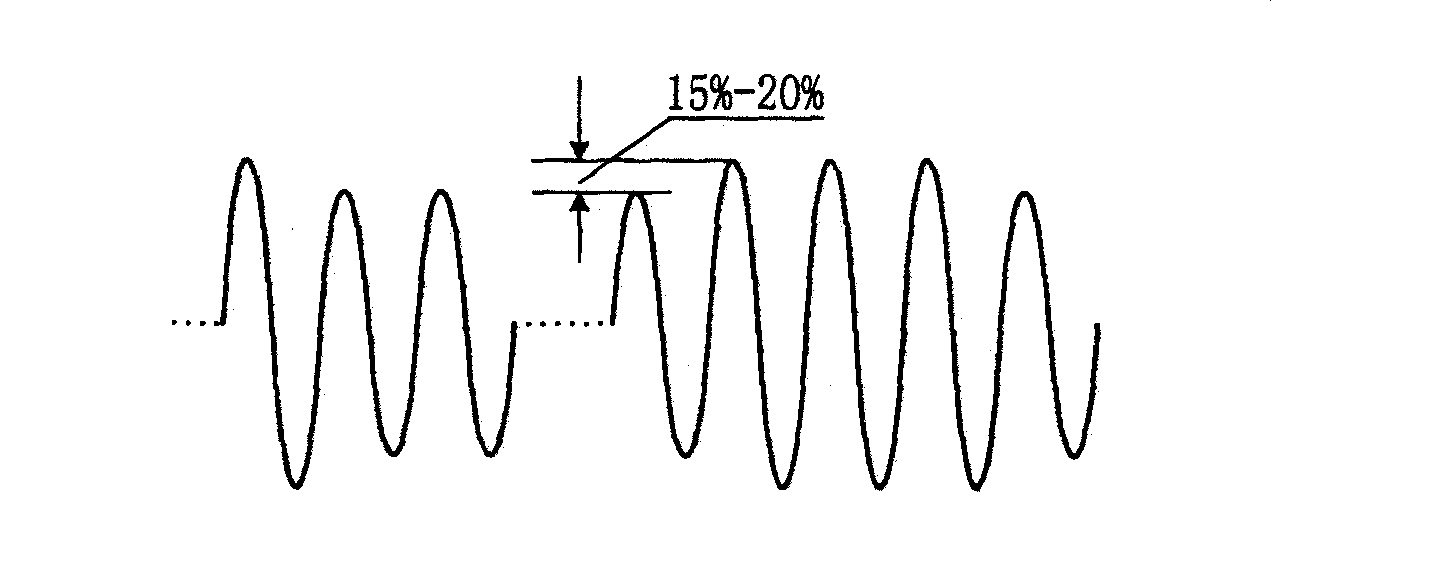

[0024] (1) A set value is given so that it is greater than the true RMS value of the surge current when the forging press is punching with missing parts and less than the true RMS value of the surge current when the forging press is effectively punching;

[0025] (2) In a working cycle of the forging press, sequentially detect the true effective value of the working current of the forging press in each continuous current cycle, and compare with the above-mentioned set value;

[0026] (3) If there is at least one detected current value greater than the set value in step (2), directly en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com