LED chip and thermal sediment direct encapsulated heat radiation component and its making device and method

A technology of LED chips and heat dissipation components, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems such as the structure that is not applicable to the direct packaging of chips and heat dissipation components, so as to facilitate natural convection heat dissipation, improve reliability and life, Effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

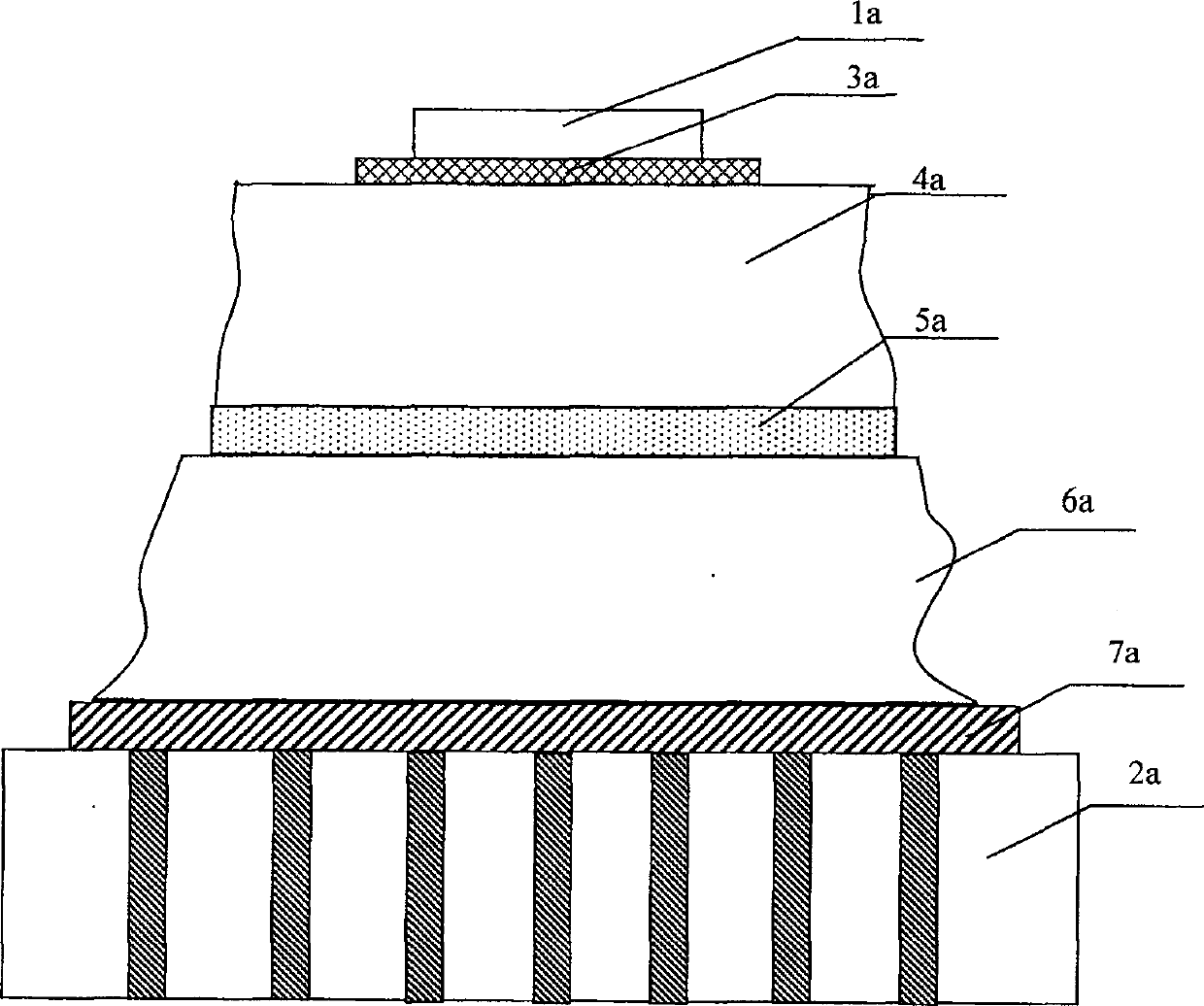

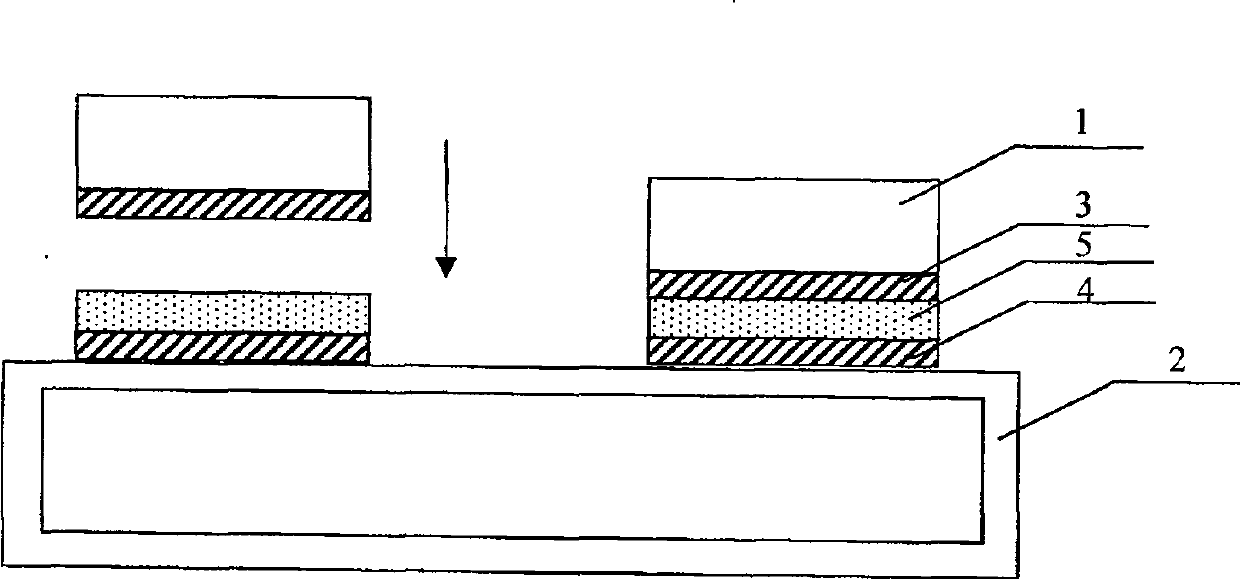

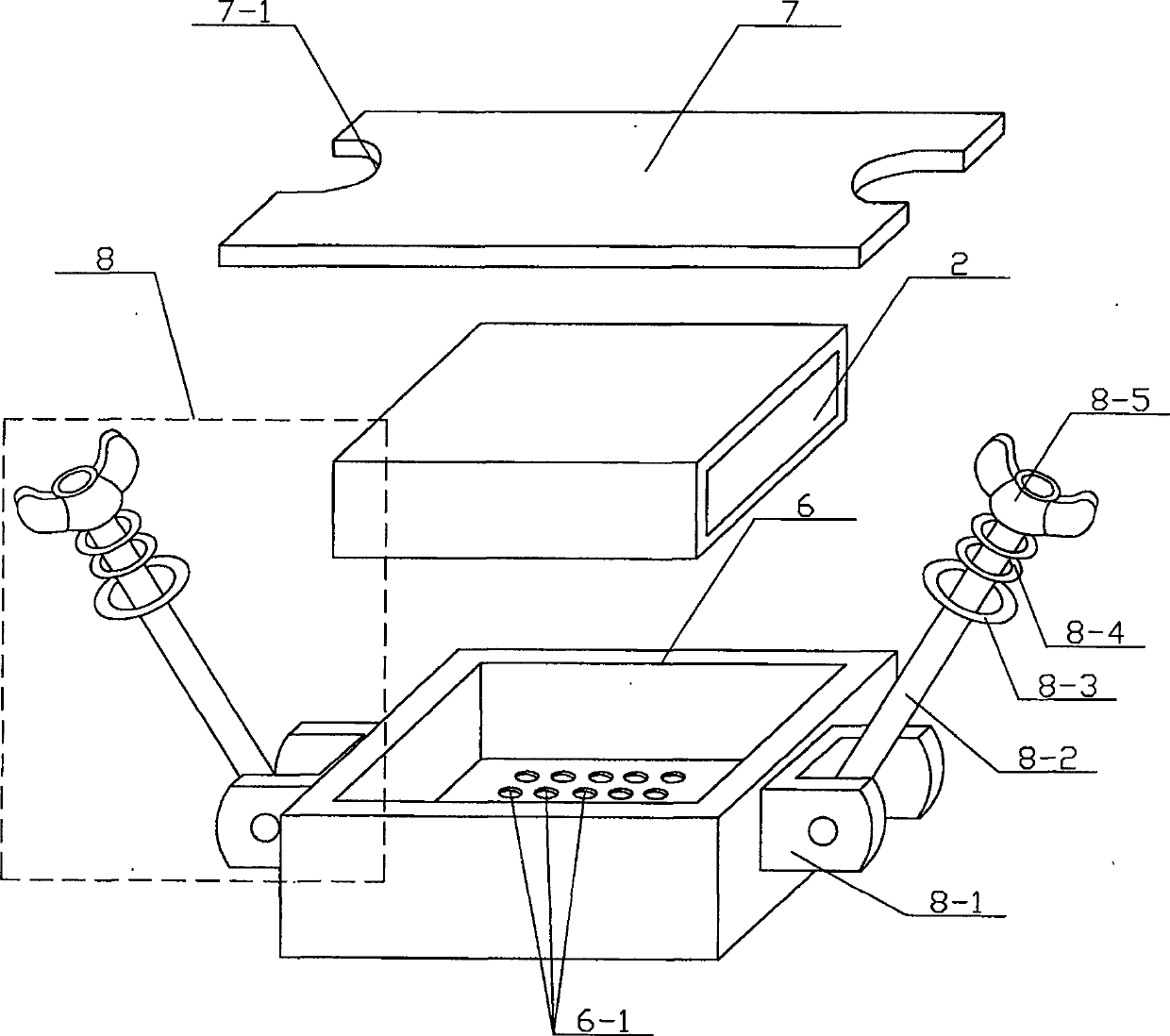

[0016] Specific implementation mode one: combine figure 2 To illustrate this embodiment, the heat dissipation assembly in which the LED chip and the heat sink are directly packaged in this embodiment is composed of an LED chip 1, a rectangular tubular heat sink 2, a chip metal film 3, a heat sink metal film 4 and a solder layer 5; The lower surface of the chip 1 is coated with a chip metal film 3, and the upper surface of the rectangular tubular heat sink 2 is coated with a heat sink metal film 4. The solder layer 5 is placed between the chip metal film 3 and the heat sink metal film 4. The metal film 3 , the heat sink metal film 4 and the solder layer 5 connect the LED chip 1 and the rectangular tubular heat sink 2 .

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 2 This embodiment is described. The first difference between this embodiment and the specific embodiment is that the rectangular tubular heat sink 2 is made of copper or aluminum metal. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is that the chip metal film 3 and the heat sink metal film 4 are made of gold Au or silver Ag. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com