Heat dissipation method of LED light source

A technology of LED light source and heat dissipation method, applied in the field of heat dissipation, can solve the problems of heavy weight of heat dissipation module, high center temperature, poor heat dissipation, etc., and achieve the effects of improved heat dissipation efficiency, rapid heat dissipation, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiment:

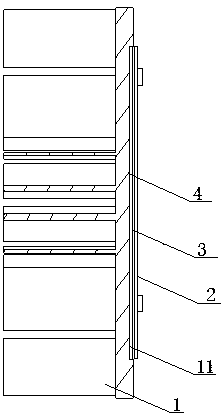

[0032] like figure 1 Shown, a kind of heat dissipation method of LED light source, comprises the following steps:

[0033] (1) Forging industrial pure aluminum into a heat dissipation module 1, one side of the heat dissipation module 1 is provided with a groove 11 corresponding to the size of the LED circuit board;

[0034] (2) Prepare the LED circuit board 2 with an insulating layer inside;

[0035] (3) An aluminum substrate 3 with high thermal conductivity is arranged closely under the LED circuit board 2;

[0036] (4) Thermally conductive silicone grease 4 is provided in the groove 11 of the heat dissipation module 1 , and the aluminum substrate 3 is put into the groove 11 and fastened with screws.

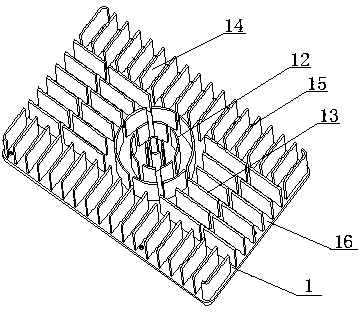

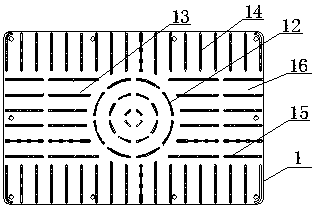

[0037] Preferably, the heat dissipation module 1 in the step (1) is as follows: putting industrial pure aluminum into a forging press for integral mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com