Integral device for data storage and on spot bus communication

A field bus and data storage technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of inability to guarantee high-speed real-time storage, complicated wiring of robot control cabinets, and the system being susceptible to external interference. Anti-interference ability, easy to expand, reduce the effect of interference between lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

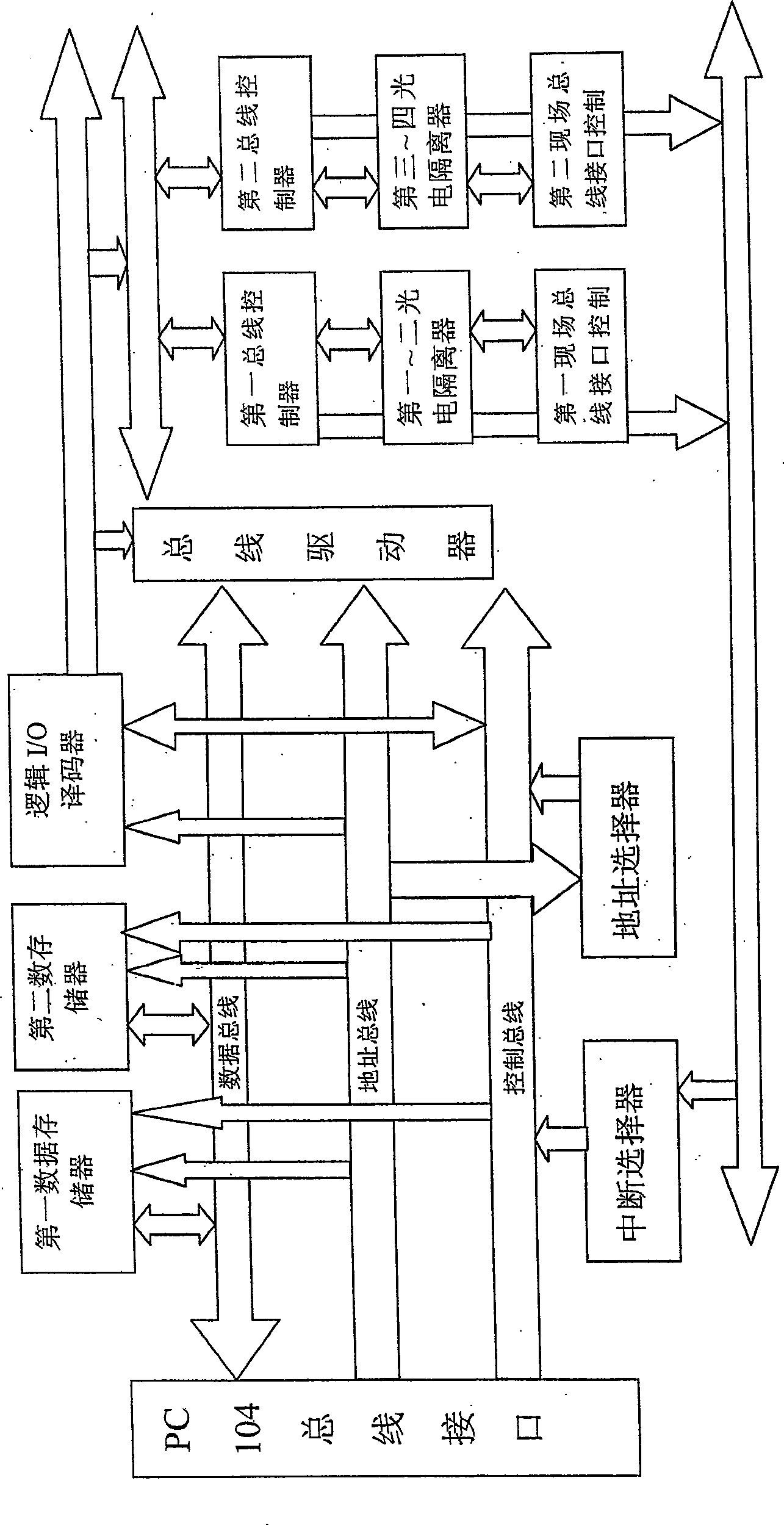

[0032] like Figure 1~4 As shown, the present invention comprises: data storage unit, fieldbus communication unit, logic control unit and external control interface unit four parts, with PC104 bus interface as and control device data interaction interface, with external control unit to data storage unit and fieldbus The communication unit performs control as follows:

[0033] The external control interface unit communicates with the external control device. specifically is:

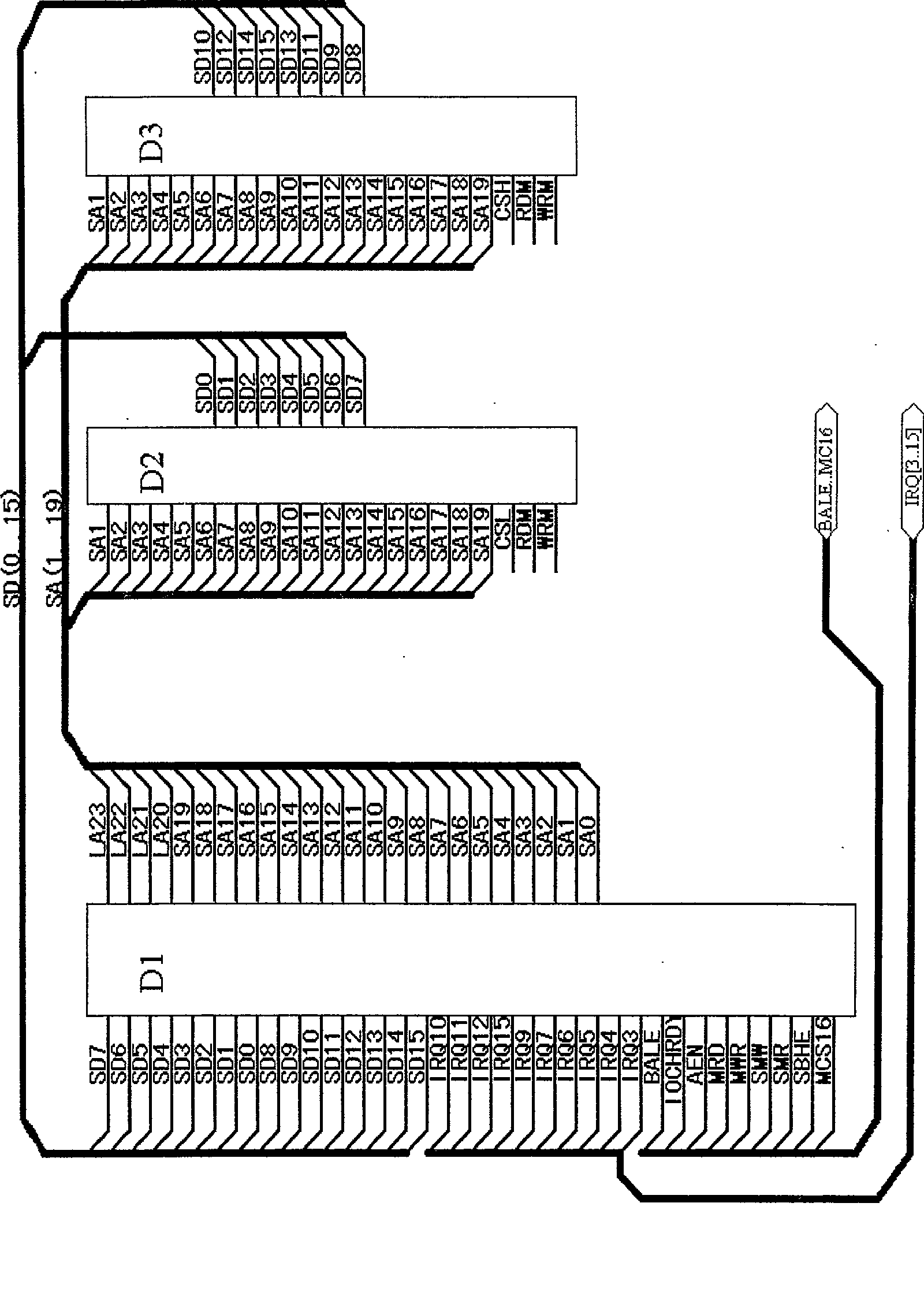

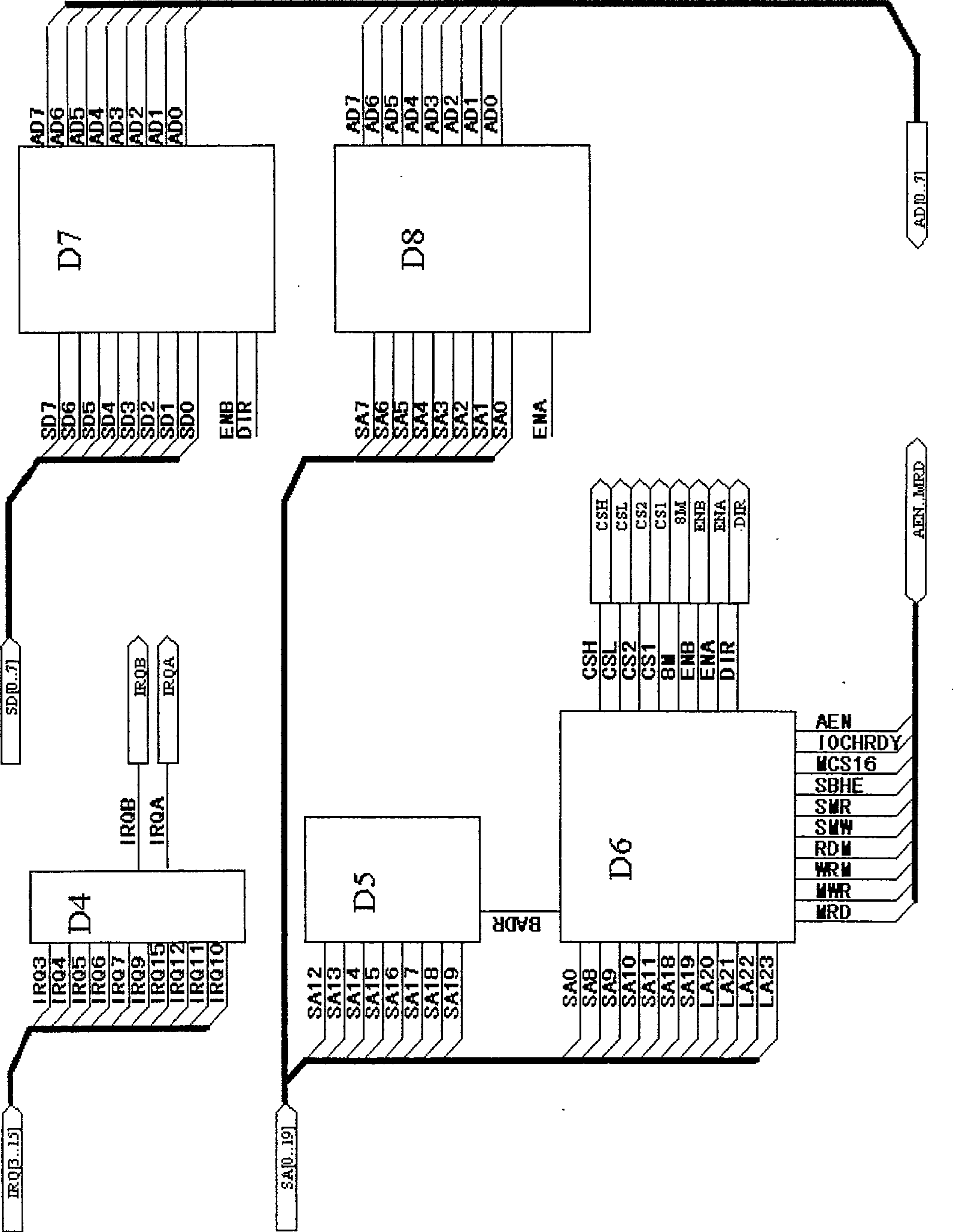

[0034] PC104 bus interface D1, said PC104 bus interface D1 communicates with the first data memory D2, the second data memory D3, logic I / O decoder D6, address selector D5, interrupt selector D4 through data, address bus, control signal , the first to second data bus drivers D7 to D8 are connected;

[0035] The data storage unit receives the control signal of the logic I / O decoder in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com