Hollow slab mounted permanent sectional pattern member and implement method thereof

An implementation method and hollow slab technology, which can be applied to building materials and other directions, can solve the problems of increased construction workload and troublesome construction, and achieve the effect of promoting the development of construction technology, reducing workload and good crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is realized in the following manner:

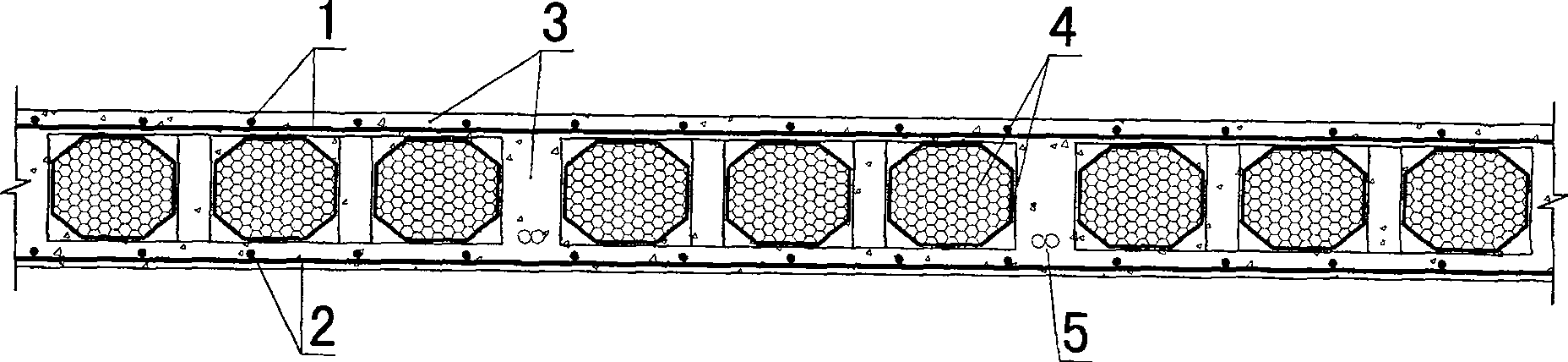

[0038] exist figure 1 Among them, the thickness of the hollow slab is 180-350mm. The hollow slab includes the upper steel bar (1), the lower steel bar (2), concrete (3), and the combined module (4). The combined module (4) is located between the upper steel bar (1) and the Between the steel bars (2) of the lower layer, they are permanently buried in the concrete (3). When the span of the hollow slab is large or the load is large, prestressed tendons (5) can be arranged in the inter-block ribs (9).

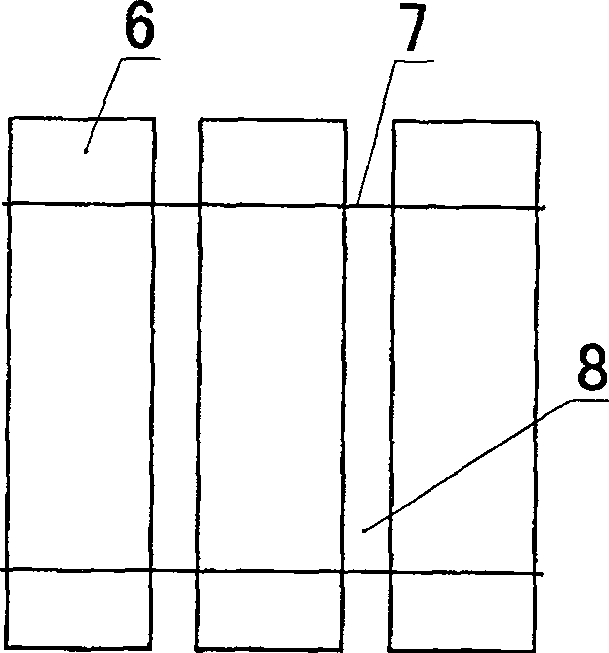

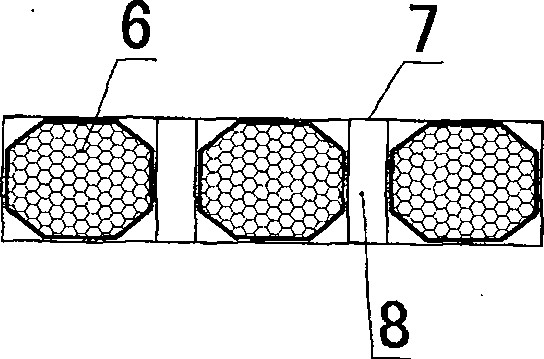

[0039] exist figure 2 , image 3 In the shown embodiment, the combined module (4) is formed by combining rod-shaped fillers (6) and grids (7). In each combined module (4), between adjacent rod-shaped fillers (6) An inner rib (8) is provided, the width of the inner rib (8) is 40-100 mm, and the rod-shaped filler (6) is solid or hollow.

[0040] exist Figure 4 In the shown embodiment, inter-block ribs (9) are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com