Smoke removing, temp lowering, afterheat using and recovering system in arc furnace and its dust removing technology

A technology of recovery system and recovery method, which is applied in the waste heat recovery system and recovery field of the exhaust gas cooling in the electric arc furnace, can solve the problems such as easy condensation of dust bag, consumption of cooling water, easy blockage of dust and heat exchange, etc., to achieve reduction Cooling water volume and maintenance costs, reduce operating costs, and reduce the effect of water-cooled flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

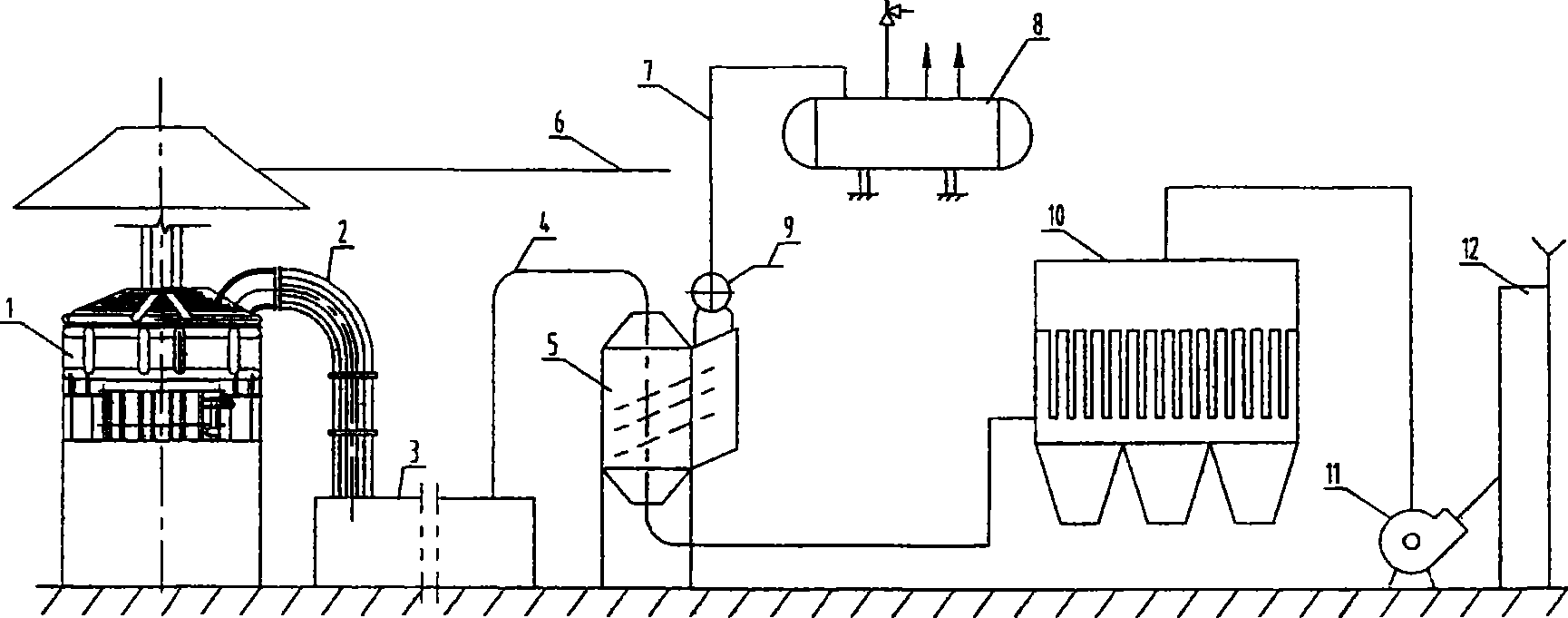

[0024] A 30t / h steelmaking electric arc furnace exhaust gas cooling waste heat utilization recovery dust removal system.

[0025] In the embodiment of the present invention, the electric arc furnace 1 is connected to the four-hole water-cooled sliding sleeve 2, the four-hole water-cooled sliding sleeve 2 is connected to the combustion settling chamber 3, the heat pipe steam generator 5 is connected to the combustion settling chamber 3 through the heat preservation pipe 4, and the heat pipe steam generator 5 passes through The pipeline is connected with the dust collector 10, and the dust collector 10 is connected with the main fan 11 through the pipeline, and the main fan 11 is connected with the exhaust tube 12. The heat pipe steam generator 5 is connected with the main water supply pipeline 9 , the main water supply pipeline 9 is connected with the main steam pipeline 7 , and the main steam pipeline 7 is connected with the steam accumulator 8 . The outer pipeline 6 is connec...

Embodiment 2

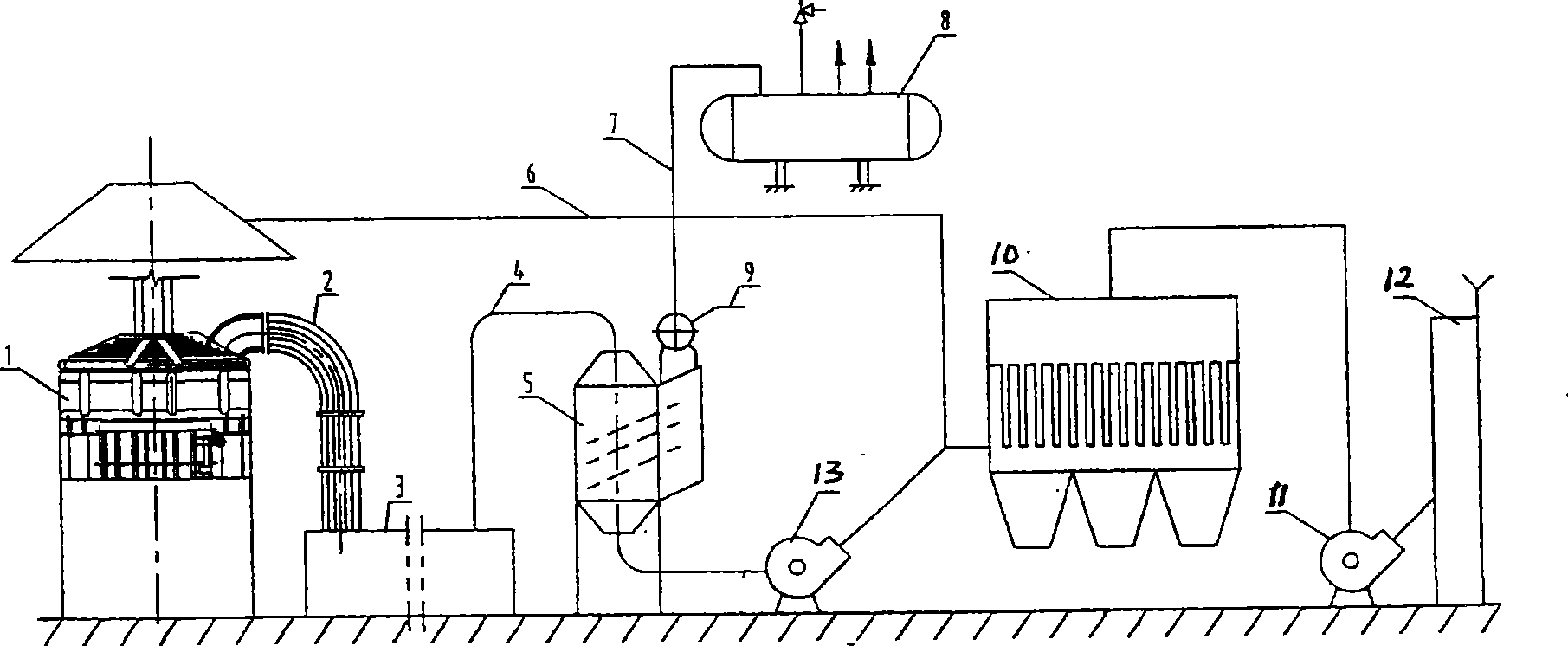

[0028] A 45t / h steelmaking electric arc furnace exhaust gas cooling waste heat utilization recovery dust removal system.

[0029] In the embodiment of the present invention, the electric arc furnace 1 is connected to the four-hole water-cooled sliding sleeve 2, the four-hole water-cooled sliding sleeve 2 is connected to the combustion settling chamber 3, the heat pipe steam generator 5 is connected to the combustion settling chamber 3 through the heat preservation pipe 4, and the heat pipe steam generator 5 passes through The pipeline is connected to the booster fan 13, and the booster fan 13 is connected to the dust collector 10 together with the outer discharge pipeline 6 connected to the top of the electric arc furnace 1. The dust collector 10 is connected to the main fan 11 through the pipeline, and the main fan 11 is connected to the exhaust tube 12. The heat pipe steam generator 5 is connected with the main water supply pipeline 9, and the main water supply pipeline 9 is ...

Embodiment 3

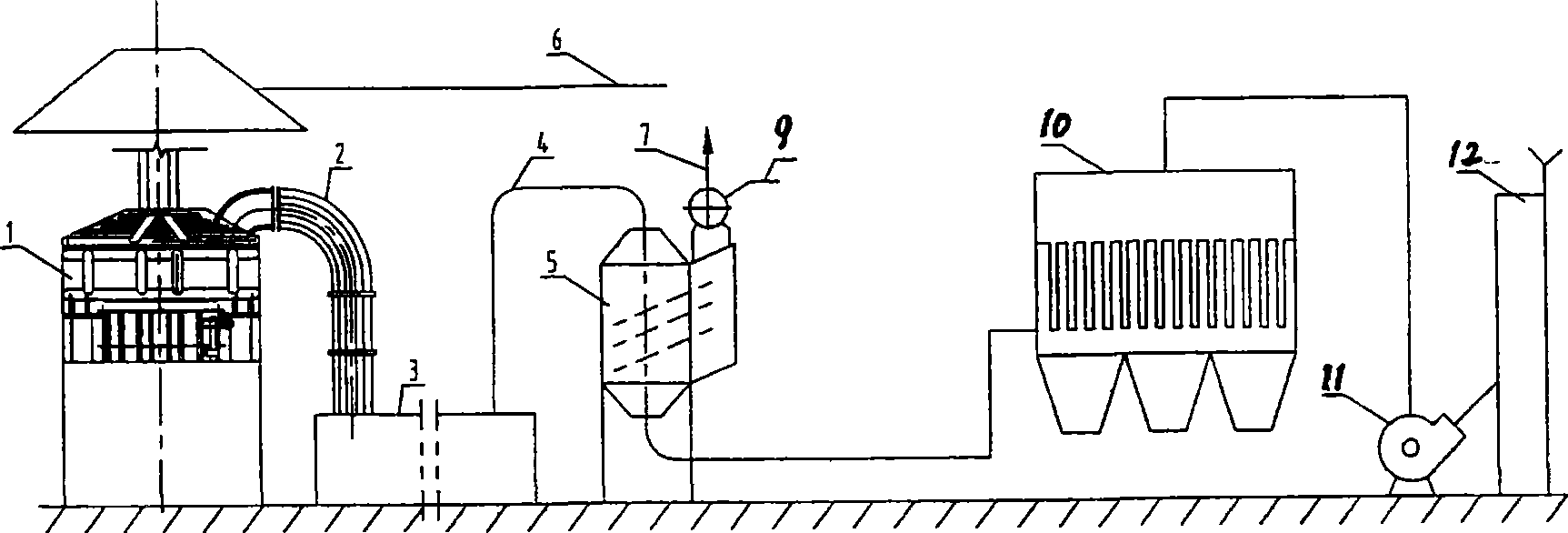

[0032] A 50t / h steelmaking electric arc furnace exhaust gas cooling waste heat utilization recovery dust removal system.

[0033] In the embodiment of the present invention, the electric arc furnace 1 is connected to the four-hole water-cooled sliding sleeve 2, the four-hole water-cooled sliding sleeve 2 is connected to the combustion settling chamber 3, the heat pipe steam generator 5 is connected to the combustion settling chamber 3 through the heat preservation pipe 4, and the heat pipe steam generator 5 passes through The pipeline is connected with the dust collector 10, and the dust collector 10 is connected with the main fan 11 through the pipeline, and the main fan 11 is connected with the exhaust tube 12. The main water supply pipeline 9 is connected to the heat pipe steam generator 5, and the main water supply pipeline 9 is connected to the main steam pipeline 7. The outer pipeline 6 is connected above the electric arc furnace 1 .

[0034] Such as image 3 As shown:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com