PVDC casing sandwiched printing package film and method for producing same

A printing packaging and packaging film technology, applied in printing, packaging, wrapping paper, etc., can solve the problems of high production cost, large ink content, and large solvent residue, and achieve low production cost, less ink volume, and less solvent residue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

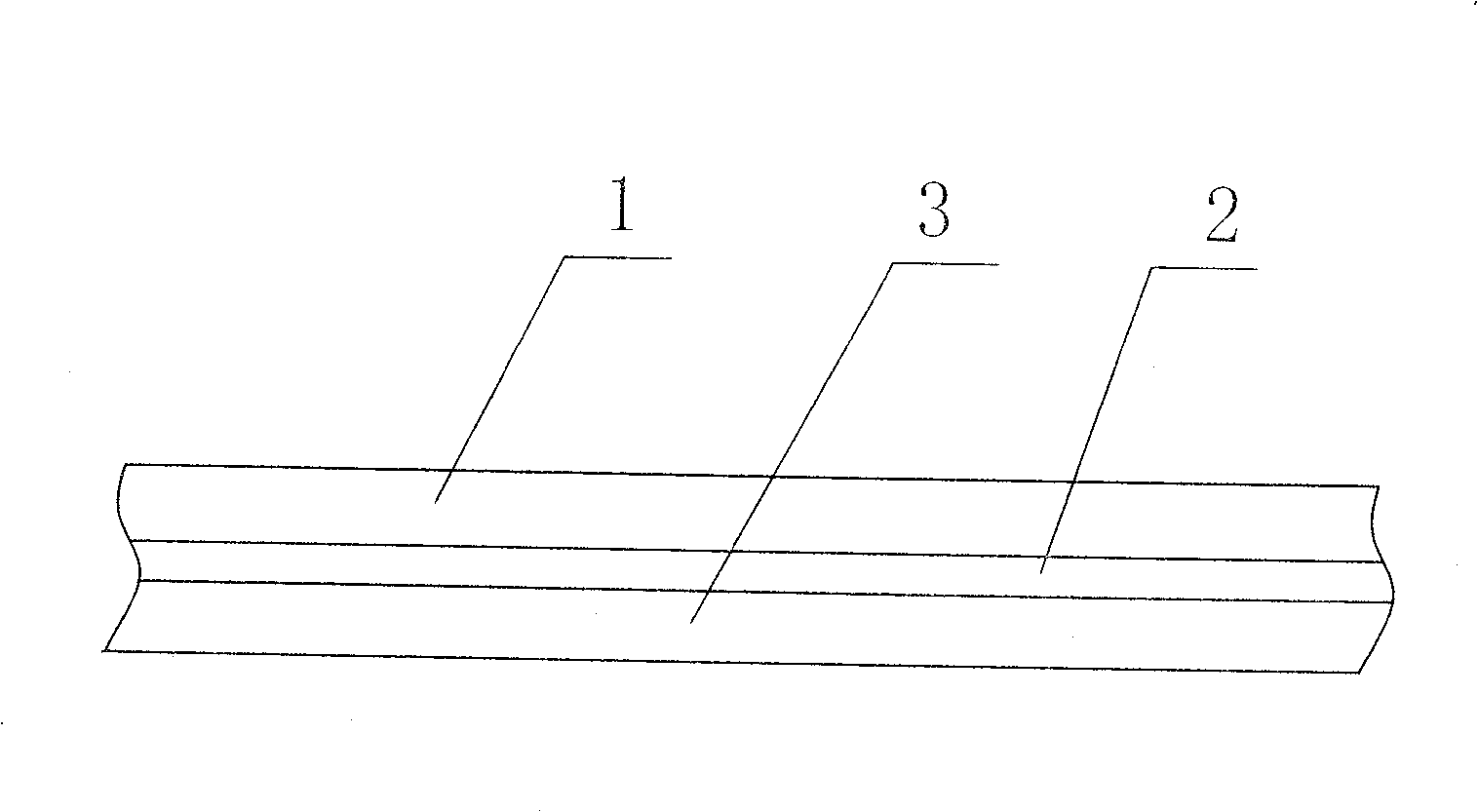

[0019] As shown in the figure, this PVDC casing interlayer printed packaging film includes an outer layer 1 and an inner layer 3 that are combined together. The outer layer 1 is a transparent PVDC film, and the inner layer 3 is a white PVDC film. The printing ink layer 2 of printing printing. The back printing ink layer 2 is a polyurethane back printing ink resistant to 121° C. high-temperature cooking solvent. The thickness of the outer transparent PVDC film and the thickness of the inner white PVDC film are both 10-30 μm, and the thickness of the ink layer is 2-4 μm. Of course, the thickness of each layer can be adjusted according to actual conditions.

[0020] The method for preparing the PVDC casing interlayer printed packaging film of the present invention is as follows: the transparent PVDC film is printed with the inner printing printing ink, and then the printing surface of the printed transparent PVDC film is compounded with the white PVDC film by using a compound ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com