Cap of fuel tank of general purpose petrol engine

A general-purpose gasoline engine and fuel tank cover technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as safety hazards, combustion, gasoline waste, etc., and achieve the effect of preventing fuel tank explosions

Inactive Publication Date: 2009-07-22

LONCIN MOTOR

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the ventilation structure of the fuel tank cover of this general-purpose gasoline engine is always connected. When the gasoline engine is tilted too large or dumped, the gasoline in the fuel tank will flow out along this ventilation channel, which will cause gasoline waste and pollute the environment. , it is also easy to cause combustion and explosion, and there is a serious safety hazard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

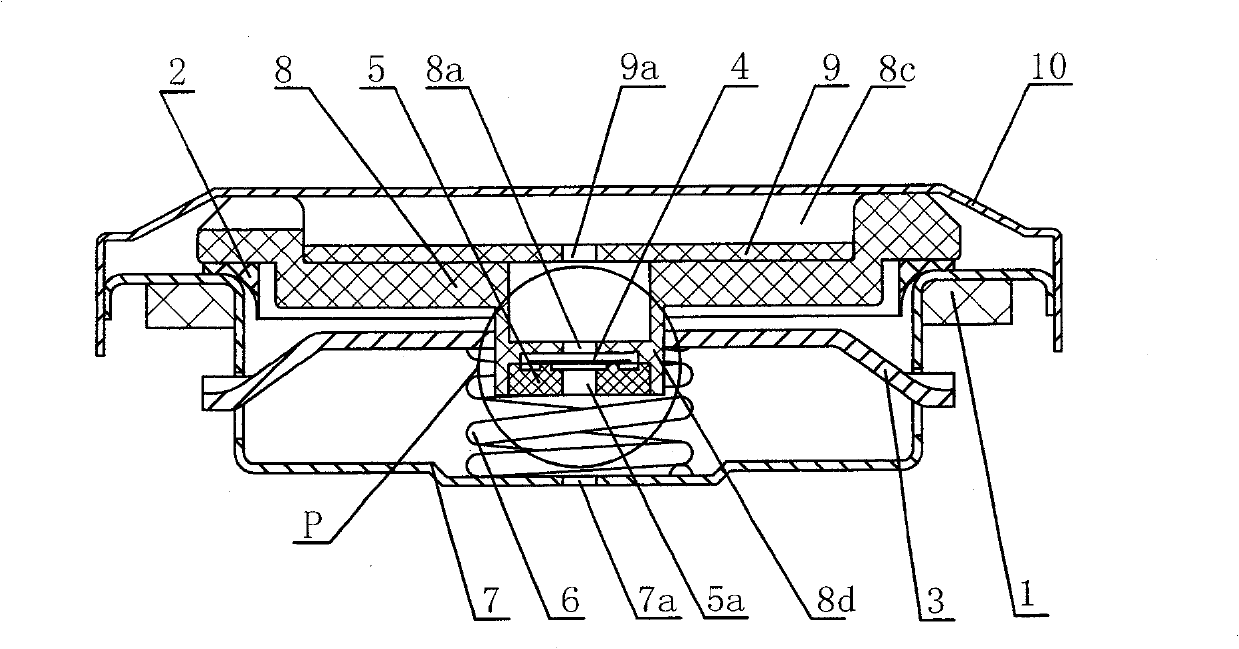

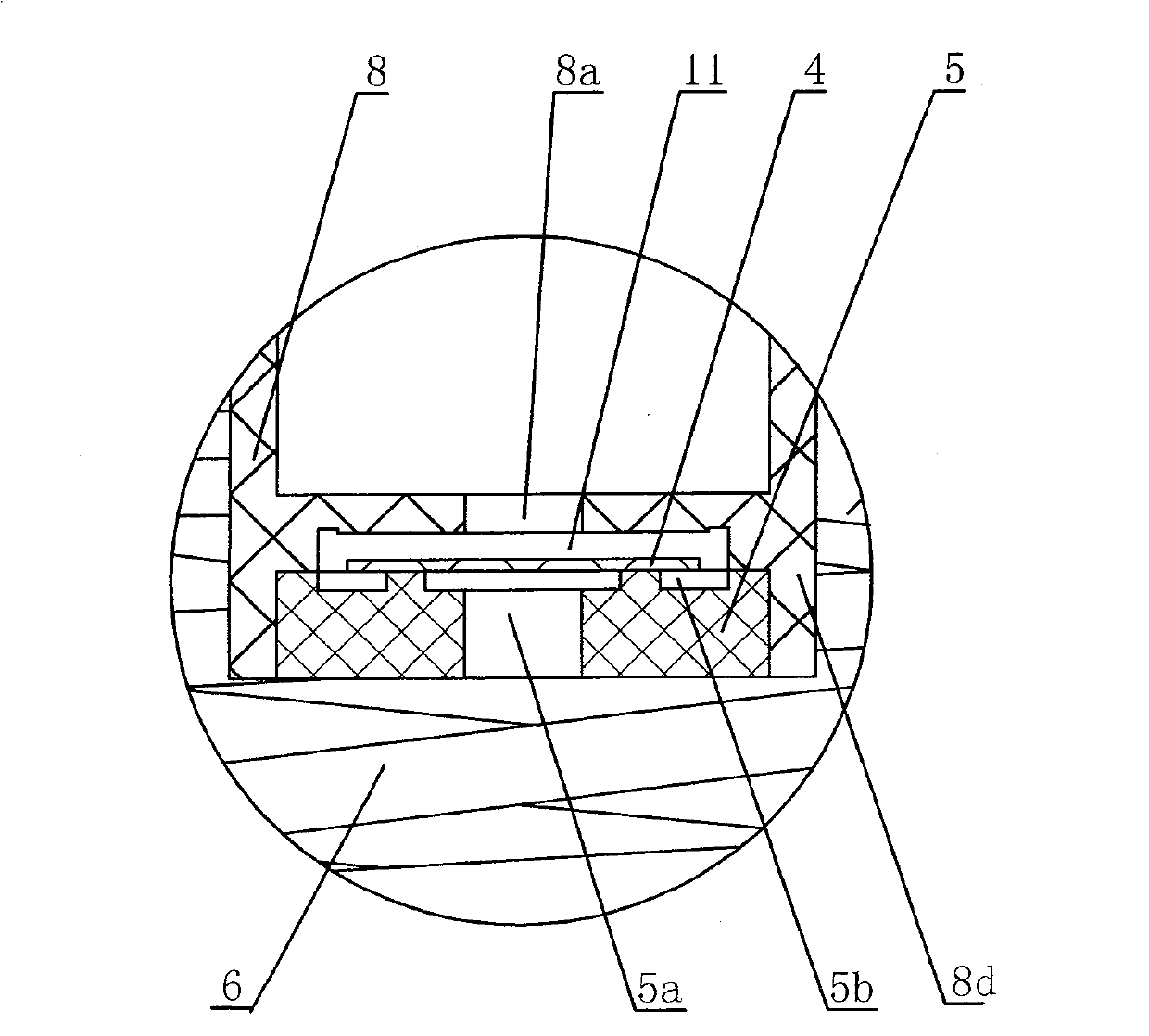

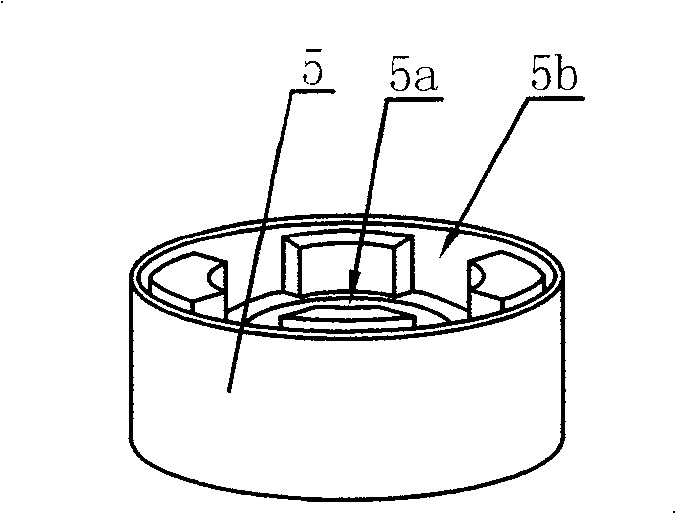

The invention discloses a petrol cylinder cover of a universal gasoline engine. An inner cover of a through hole with steps is positioned between an enclosure of the petrol cylinder cover and a fastening combination; a piston is positioned inside a large diameter end of the through hole with steps and is provided with a through hole with a round center, which is opposite to the through hole with steps; a film which enables a small diameter hole of the through hole with steps of the inner cover to be communicated with or plug the through hole with the round center in the piston through displacement is positioned between the piston and a hole shoulder of the through hole with steps. The thickness of the film is less than the distance of the hole shoulder of the through hole with steps to the piston, while the diameter is larger than that of the through hole with the round center of the piston and the small diameter of the through hole with steps. The piston end face under the film or the hole shoulder end face of the through hole with steps is provided with a gas channel. By adopting a structure preventing petrol from flowing out in the gas passage of the petrol cylinder cover, the invention can not only ensure a communication of the cylinder internal cavity with the air under normal conditions, but also prevent petrol of the petrol cylinder from flowing out from a ventilation hole when the gasoline engine is slant greatly or is dumped.

Description

technical field The invention relates to a fuel tank cap, in particular to a fuel tank cap for a general-purpose gasoline engine. Background technique Referring to Fig. 6, the fuel tank cap of the existing general-purpose gasoline engine comprises a shell 20, a lock seat 21, a plastic plate 22, a lock plate 23, and an inner cover 24 of the fuel tank, and the shell and the lock seat are fixed by riveting, and the lock seat and the shell are fixed by riveting. A plastic plate is supported, and an inner cover of the fuel tank is arranged in the cavity at the lower end of the plastic plate, and a locking plate is fixedly connected to the lower end of the locking seat. , the fuel tank inner cover, the locking seat and the locking plate are respectively provided with ventilation holes. After the fuel tank is covered, the fuel tank cavity communicates with the atmosphere through these ventilation holes. When the gasoline engine is working, the air enters the fuel tank from the gap...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02M37/00

Inventor 刘荣利

Owner LONCIN MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com