Three-dimensional solid modeling method for toroid worm

A toroidal worm, solid modeling technology, applied to components with teeth, portable lifting devices, belts/chains/gears, etc. In-depth research on accuracy, inaccurate modeling methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

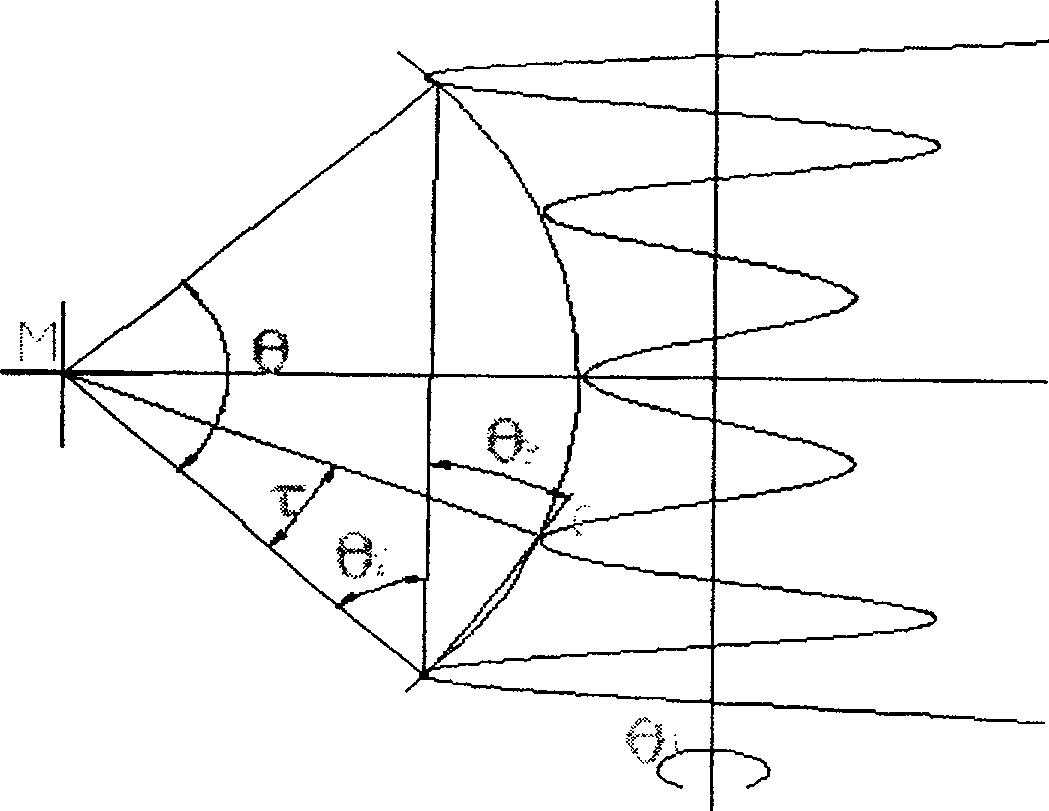

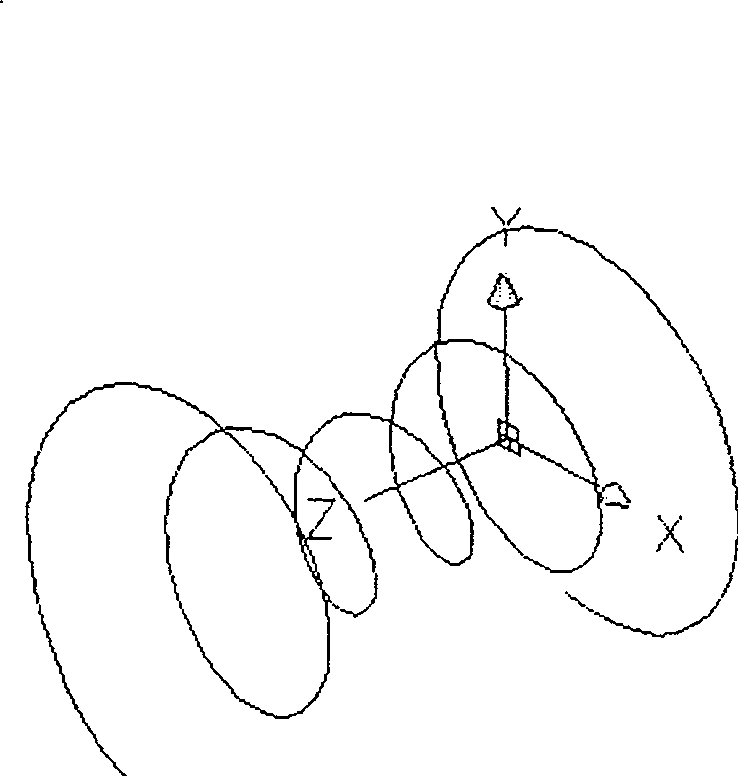

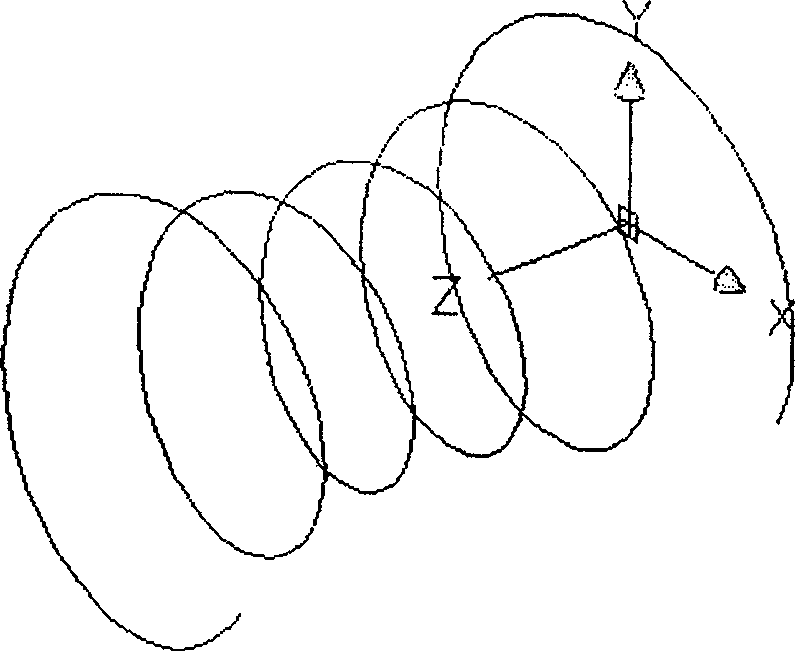

[0021] The toroidal worm helix is the key element of various toroidal worm virtual simulation entity modeling and in-depth practical research. After a lot of drawing practice and rigorous theoretical derivation, the inventor established the parametric equation of the toroidal worm helix for the first time. The process of establishing the parametric equation is described in detail below.

[0022] Theoretically, the helix of the toroidal worm can be regarded as the intersection line of two space surfaces, one of which is a circular rotating surface that rotates around the Z axis expressed by equation (1), and the other is expressed by equation (2) The cylindrical positive helicoid that rotates around the Z axis is expressed, and the equations (1) and (2) are the general analytical equations of the toroidal worm helix. Simultaneously solving the equation solutions of these two surface equations can obtain the torus worm helix.

[0023] [±(x 2 +y 2 ) 1 / 2 -(d 1 +d 2 ) / 2〕 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com