Micro flexible positioning locking mechanism

A technology of flexible positioning and locking mechanism, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems that the assembly accuracy affects the clamping consistency of micro parts, the structure of flexible positioning and locking mechanism is complicated, and it is not suitable for micro-assembly operations. , to achieve the effect of simple structure, uniform force, and avoiding precision problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the patent of the present invention are described in detail below in conjunction with technical solutions and accompanying drawings.

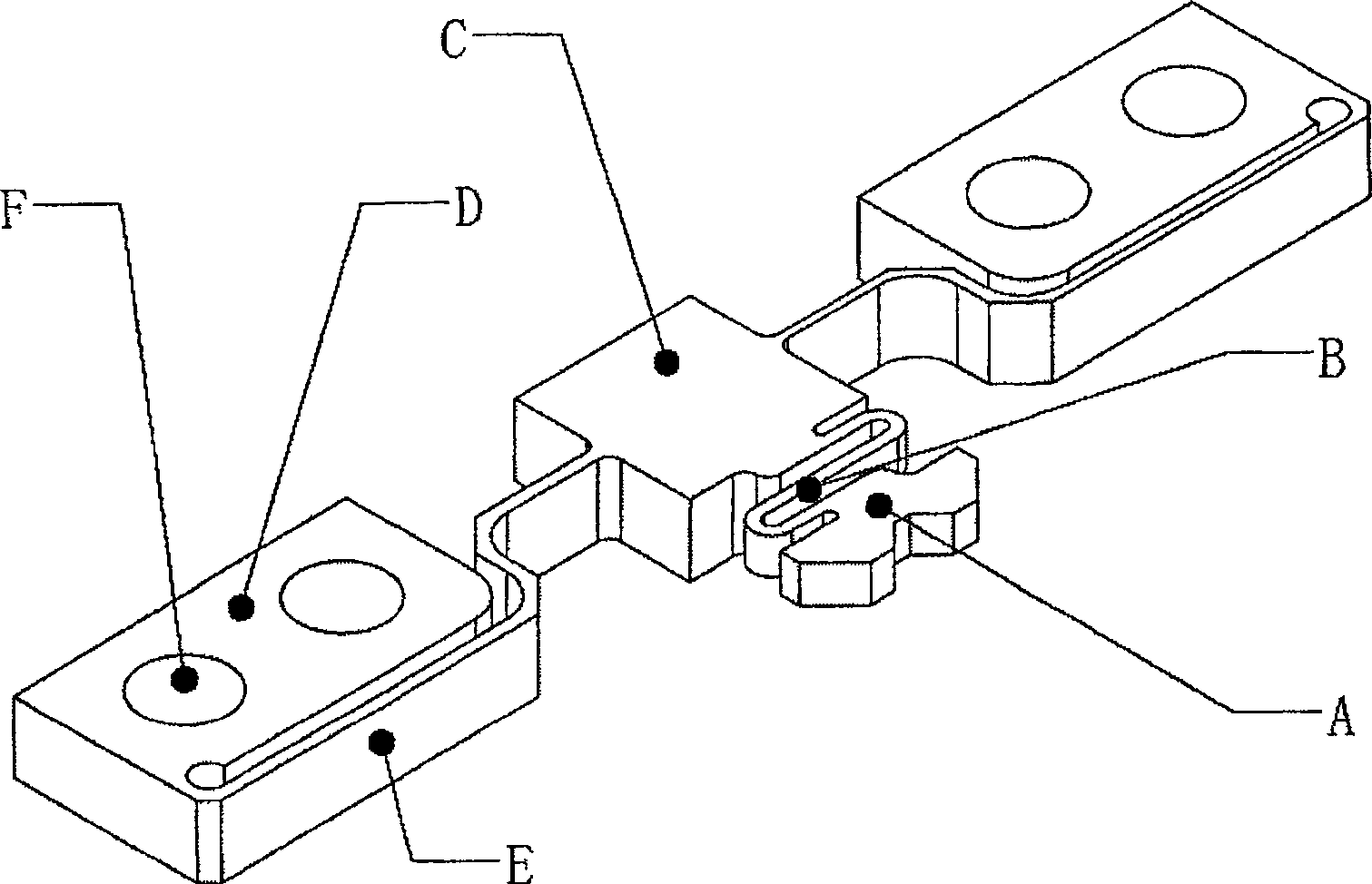

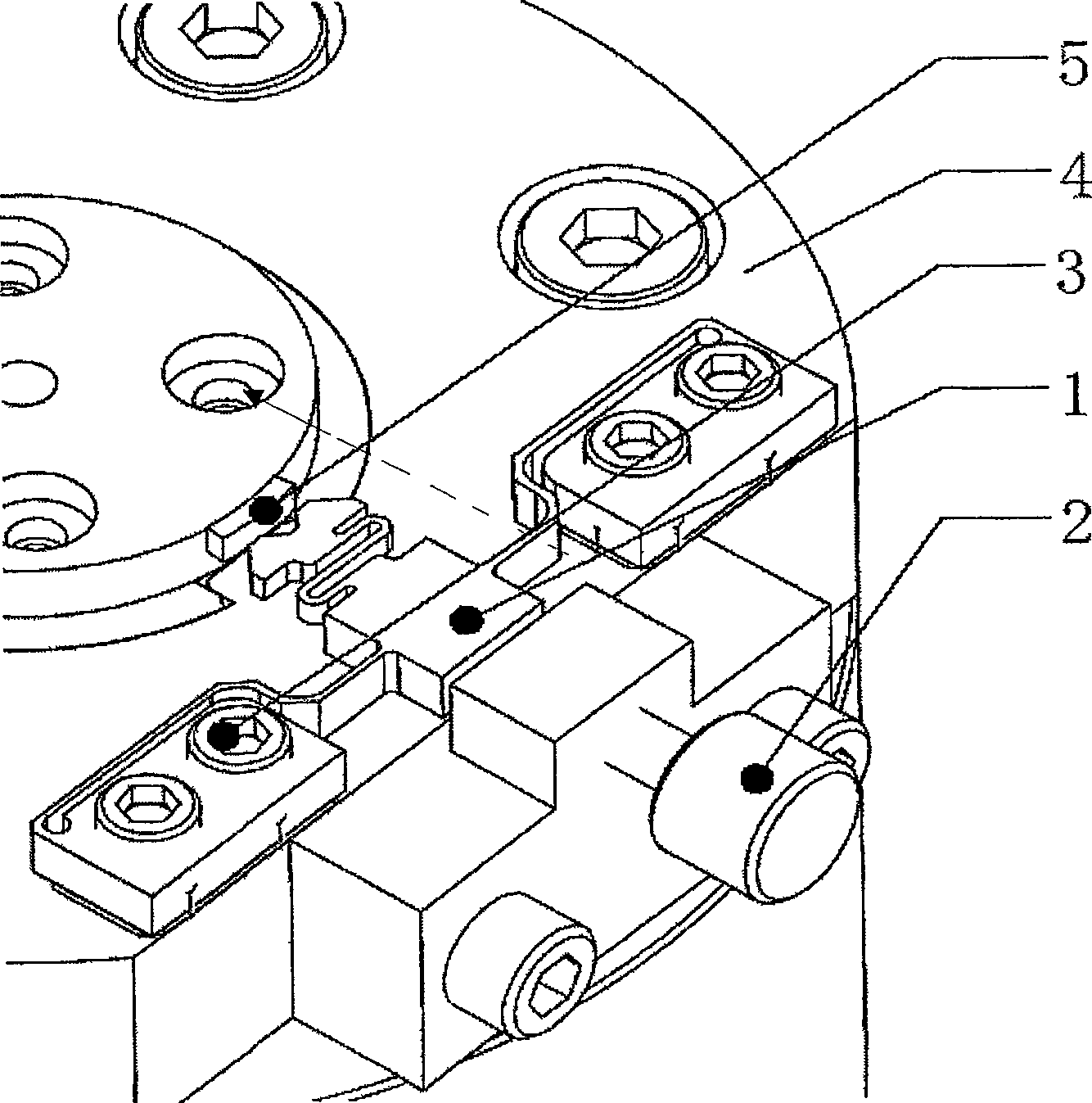

[0017] The micro-motion flexible positioning and locking mechanism is composed of three parts: an elastic positioning and locking part 1, a jacking bolt 2 and a fixing bolt 3. The elastic positioning locking part 1 is an integrated flexible part, which is composed of a V-shaped top block A, an elastic connecting block B, a force transmission block C, a fixing block D, a flexible arm E and a bolt hole F. The fixing bolt 3 is used for the positioning of the micro-motion flexible positioning locking mechanism and the turntable base 4 . Twist the tightening bolt 2, and apply the tightening force so that the force transmission block C of the locking component 1 is elastically positioned and transmitted to the V-shaped jacking block A through the elastic connecting block B. The V-shaped top block A and the assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com