Calibration device

A technology of sizing and sizing holes, applied in the field of sizing devices, can solve problems such as expensive assembly, accumulation of machining errors, strong deviation of sector brackets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

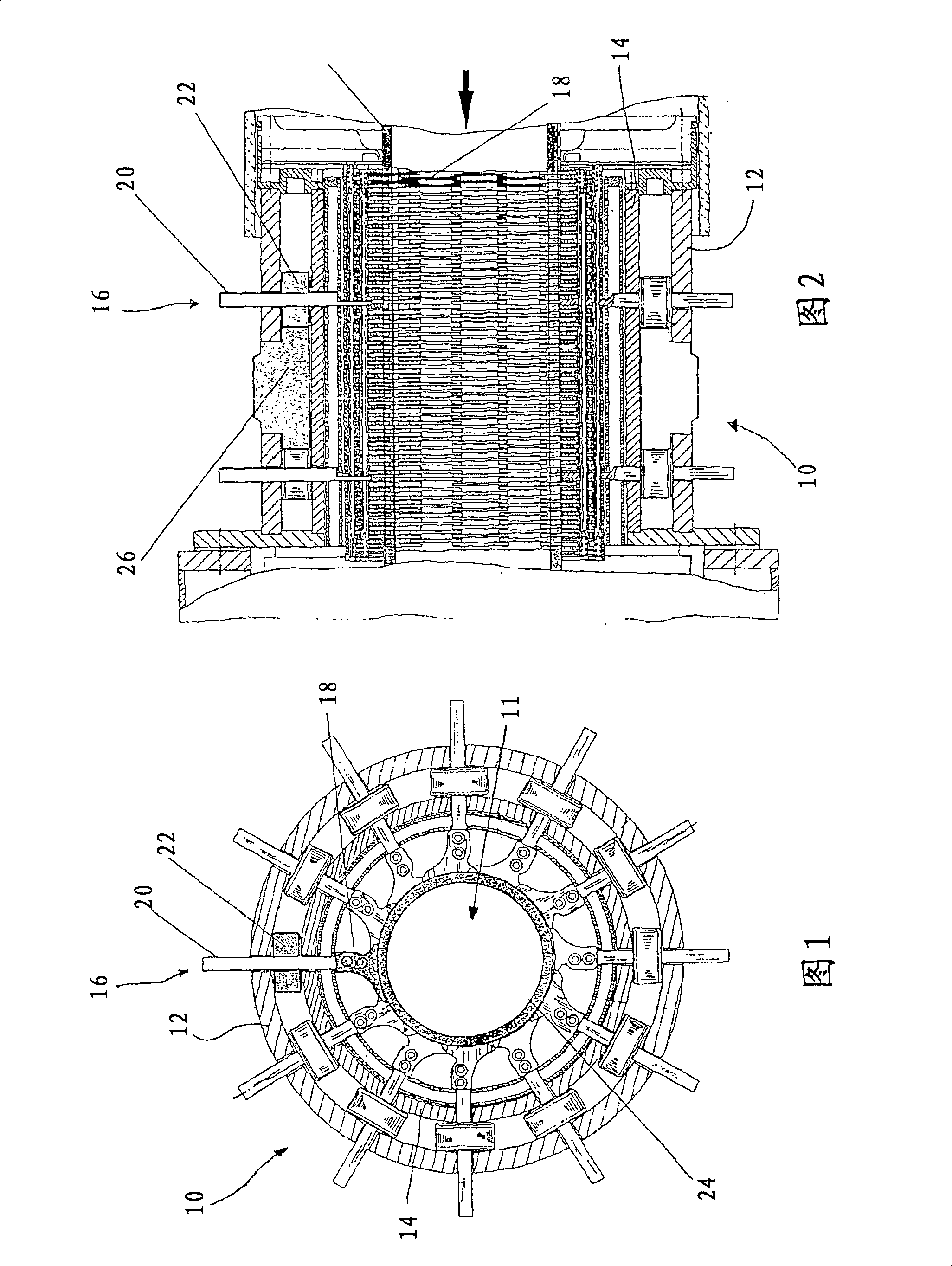

[0034] The overall structure of a device for producing plastic pipes can be found in DE 198 43 340 C2. This document shows an already adjustable sizing device. In this case, the adjustable sizing device is the core part of a tube extrusion plant with the possibility of changing dimensions. It assumes the forming task of a standard sizing, but can be infinitely adjusted via the diameter range given by the structural conditions.

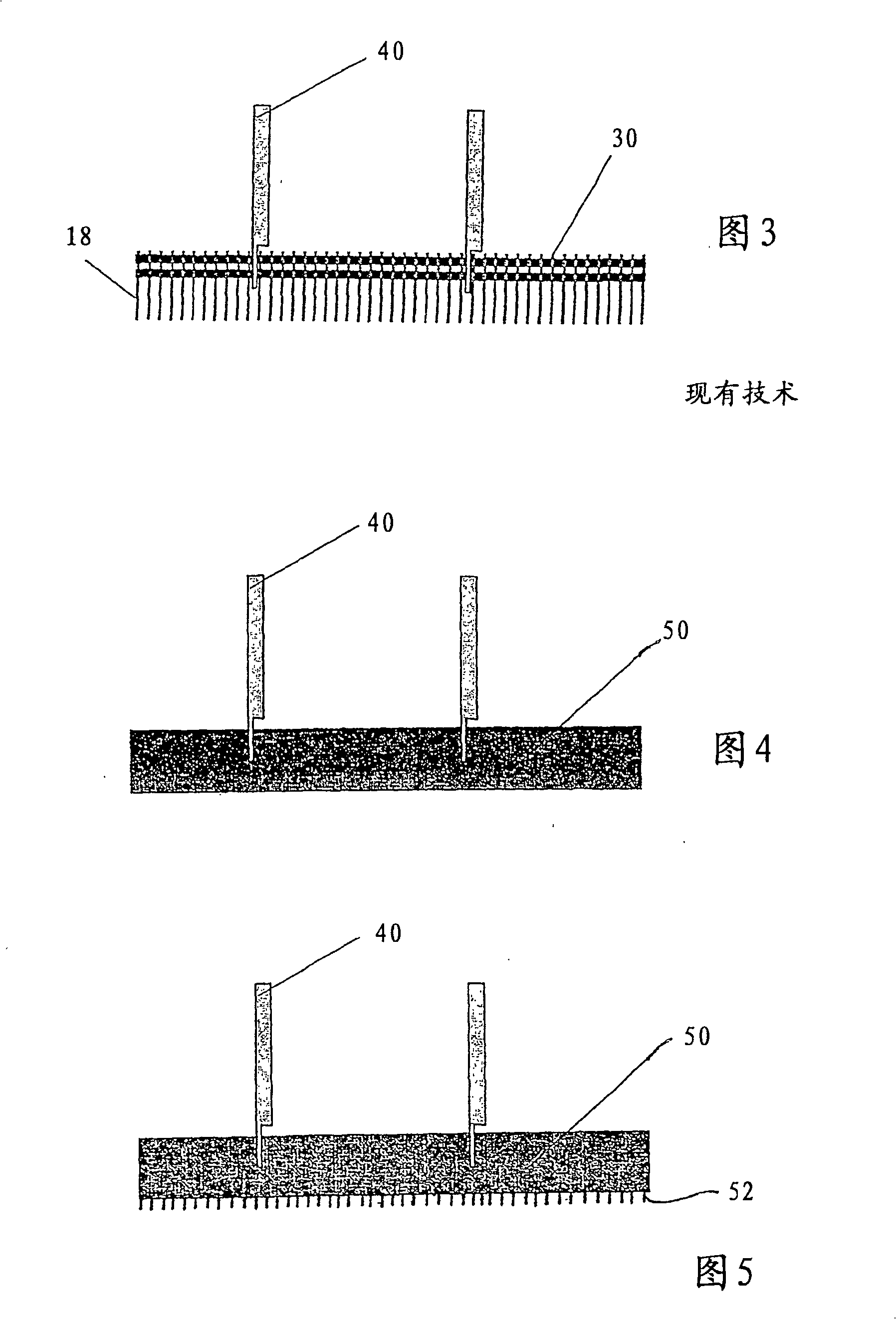

[0035] This adjustment is thus achieved in that the surface which rests on the tube is formed by a large number of individual segments. exist figure 1 The segment pieces 18 shown in have here along their inside, ie in the circumferential direction of the tube, a rounding which corresponds to the largest possible tube outer diameter and which forms the individual segment segments. These segments comprise individual laminations, which are spaced apart from one another as seen in the production direction, but are arranged closely next to each other. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com