Apparatus and method for preparing physical and chemical method improved soil samples containing directional distribution fibers

A technology for directional distribution and soil improvement, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., to achieve the effects of easy production, high sample preparation precision, and precise compaction control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

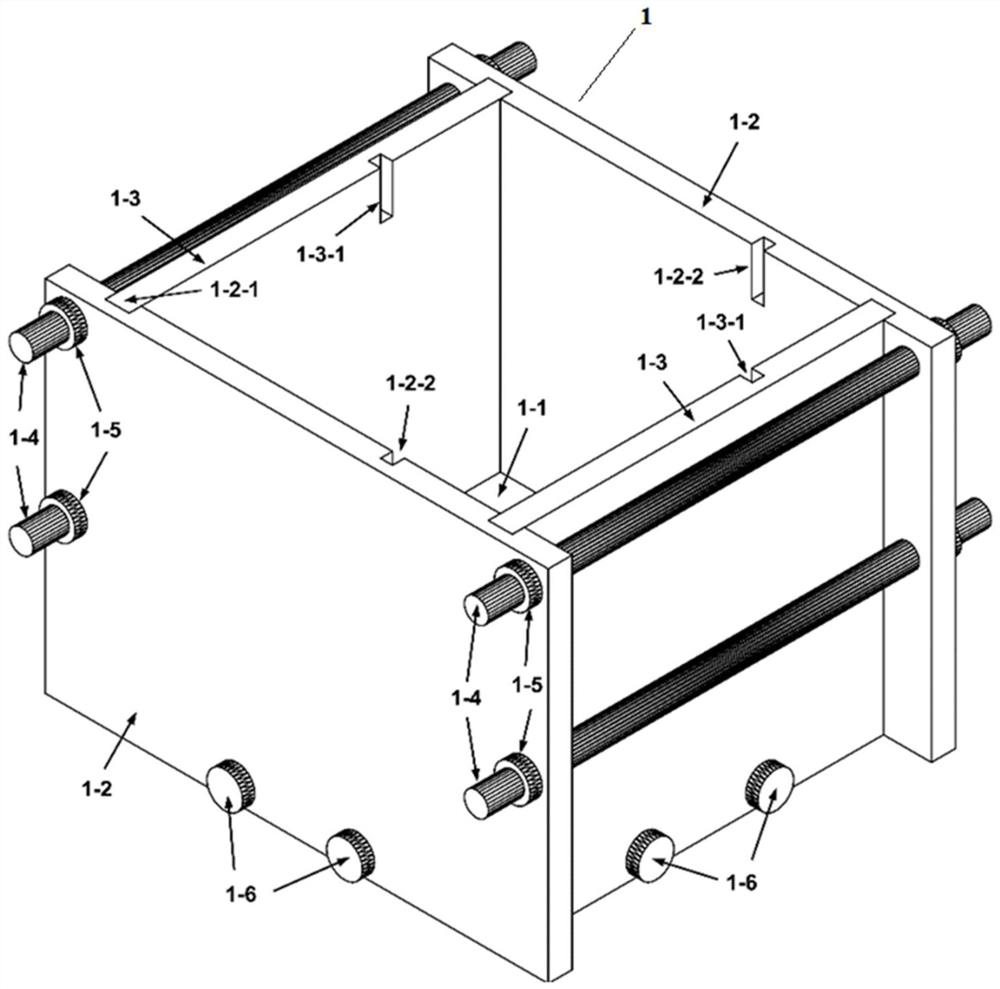

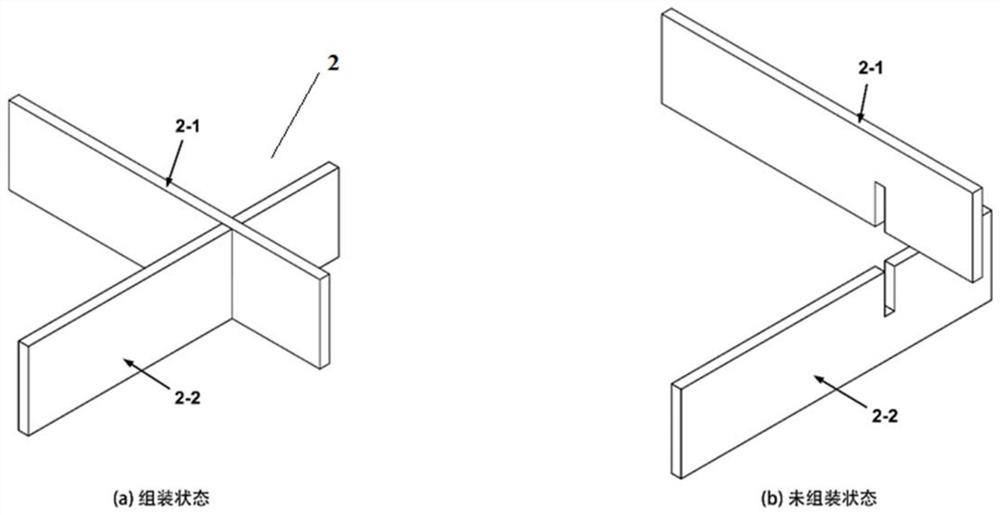

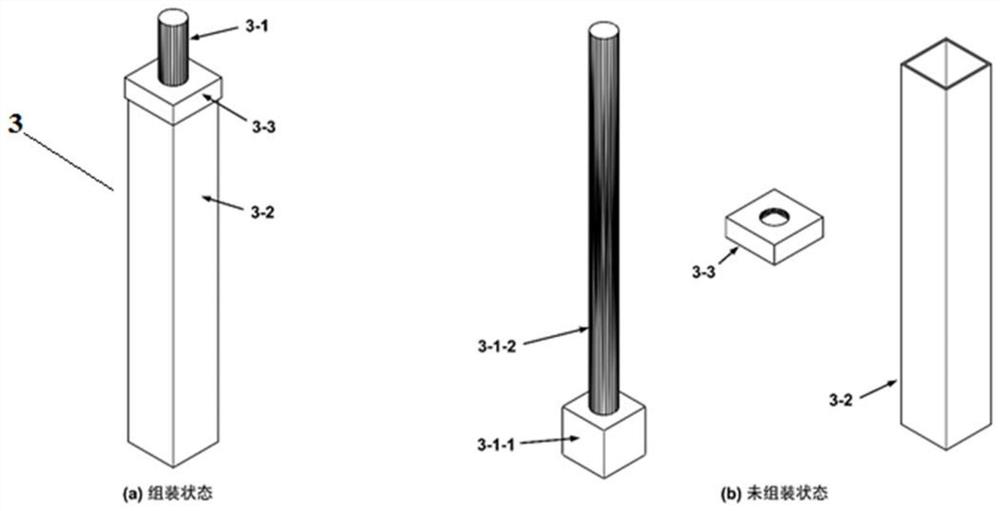

[0057] A method for preparing a triaxial compression sample of directional distributed jute fiber reinforced lime solidified expansive soil with fiber orientations of 0°, 15°, 30°, 45°, 60°, 75° and 90°.

[0058] The schematic diagram of the sample preparation process and method is as follows: Figure 7 –9 shown.

[0059] Step 1: Prepare materials. The soil to be improved is weak potential expansive soil taken from a deep foundation pit of a station on Hefei Metro Line 1. Its basic physical and mechanical properties are: natural density 2.69g / cm 3 , natural moisture content 21.3%, specific gravity 2.69, free expansion rate 53%, plastic limit 20.1%, liquid limit 42.7%, optimum moisture content 18%, maximum dry density 1.72g / cm 3 . The selected reinforcement material is jute fiber, which is one of the cheapest and most widely used natural fibers, known as "golden fiber". Of all the natural fiber types, jute has the highest tensile strength and is resistant to crushing and hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com