Laterally sliding tensioner

A tensioning device and traverse technology, which is applied in the conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems that the height and space of the workshop are difficult to meet the requirements, the height requirements of the workshop are relatively high, and the assembly requirements are high. To achieve the effect of saving height and space, flexible tensioning activities and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

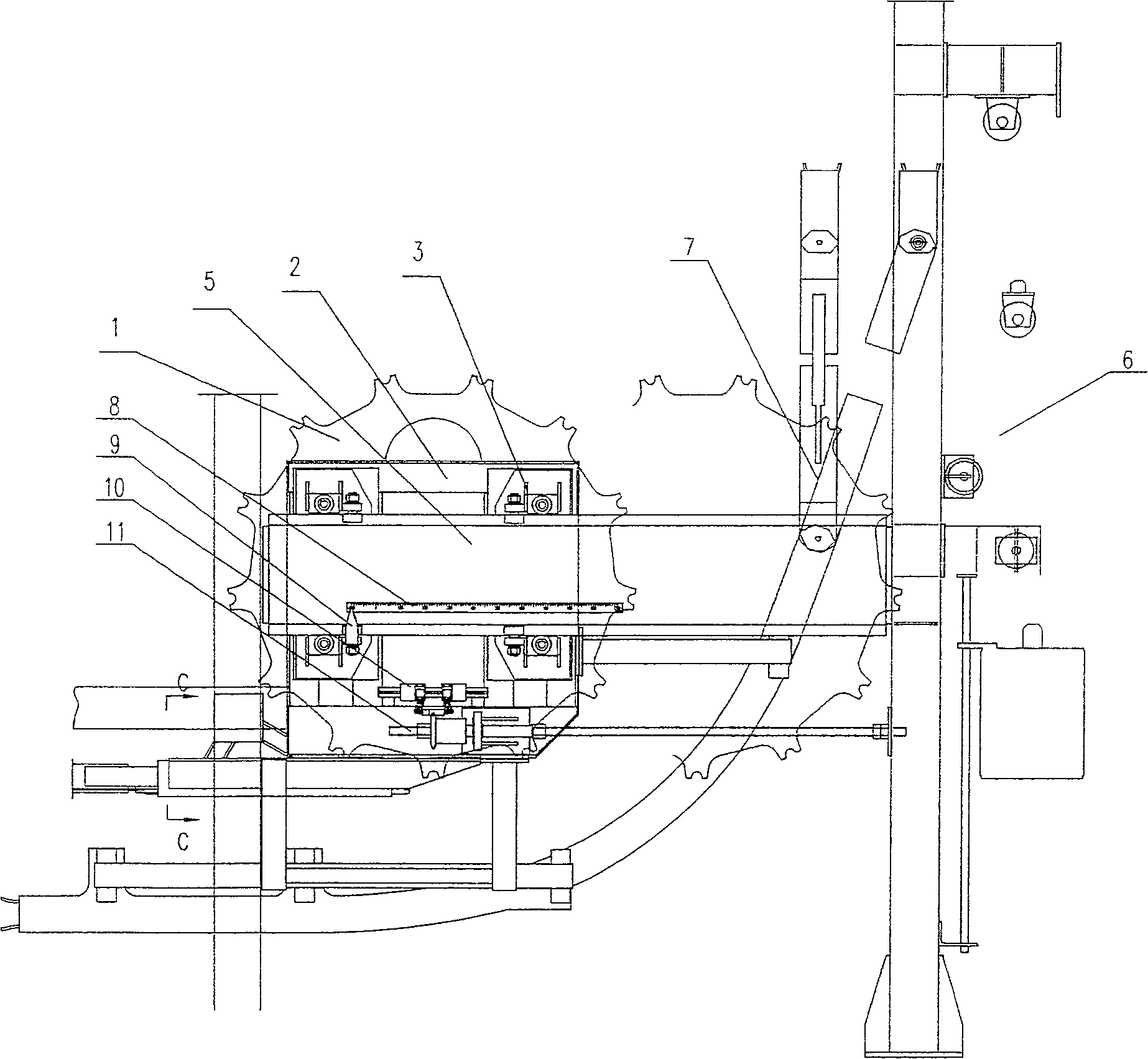

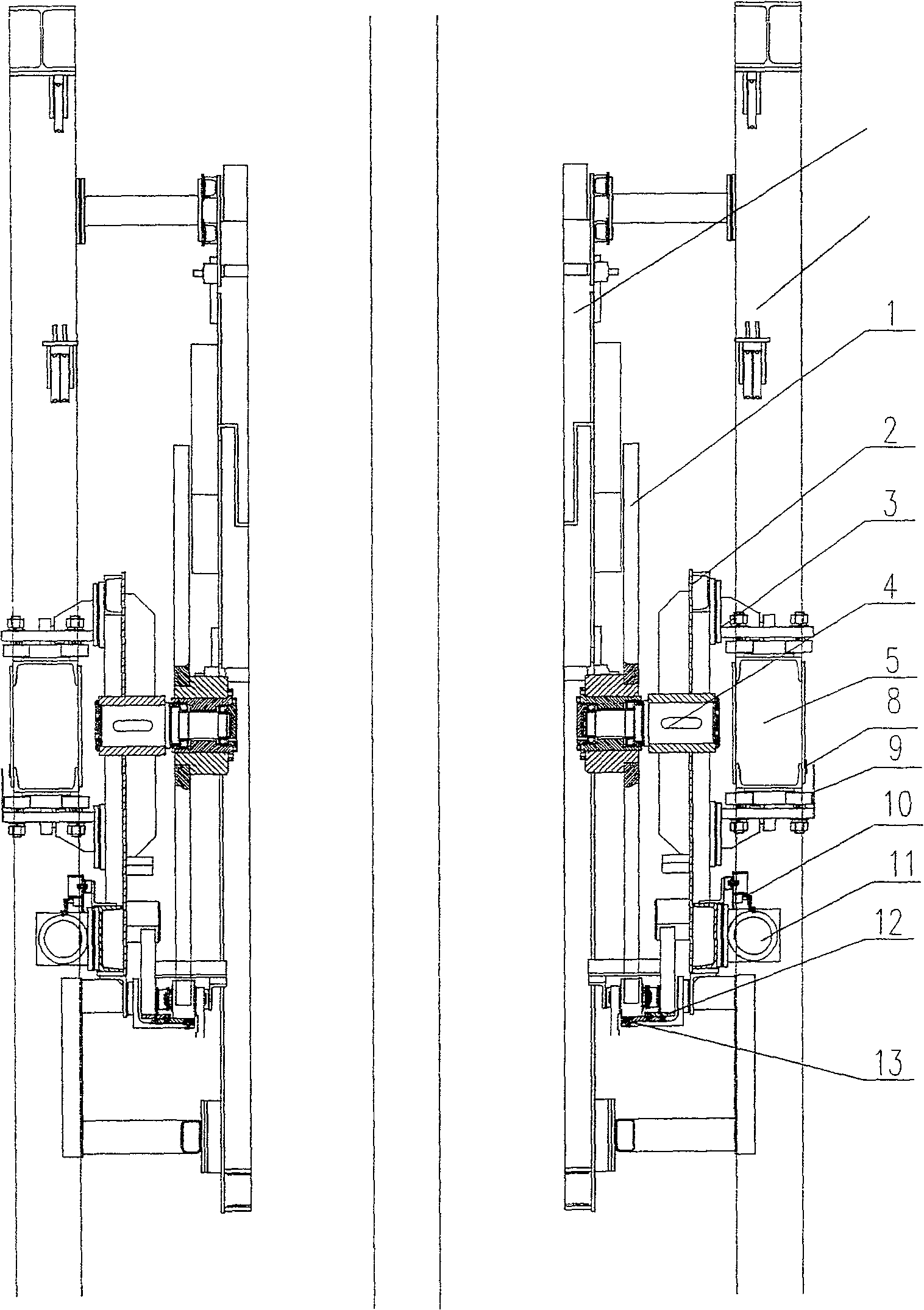

[0011] The present invention mainly consists of a tensioning sprocket 1, a tensioning movable frame 2, a guide wheel assembly 3, a shaft 4, a guide rail 5, a labor-saving counterweight device 6, a floating flip frame guide rail 7, a tensioning stroke indicating ruler 8, a tensioning Tight travel pointer 9, travel switch assembly 10, long-distance adjustable signaling device 11, chain fixed track 12, chain movable track 13 and other components.

[0012] As shown in the figure: the guide rail 5 is connected with the frame, the guide wheel assembly 3 is installed on the tensioning movable frame 2, and the tensioning movable frame 2 is movably mounted on the guide rail 5, and one end of the shaft 4 is connected to the tensioning movable frame The frame 2 is connected, the other end is connected with the tensioning sprocket 1 by a bearing, and the labor-sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com