Jet electroform method and equipment for manufacturing foamed metal

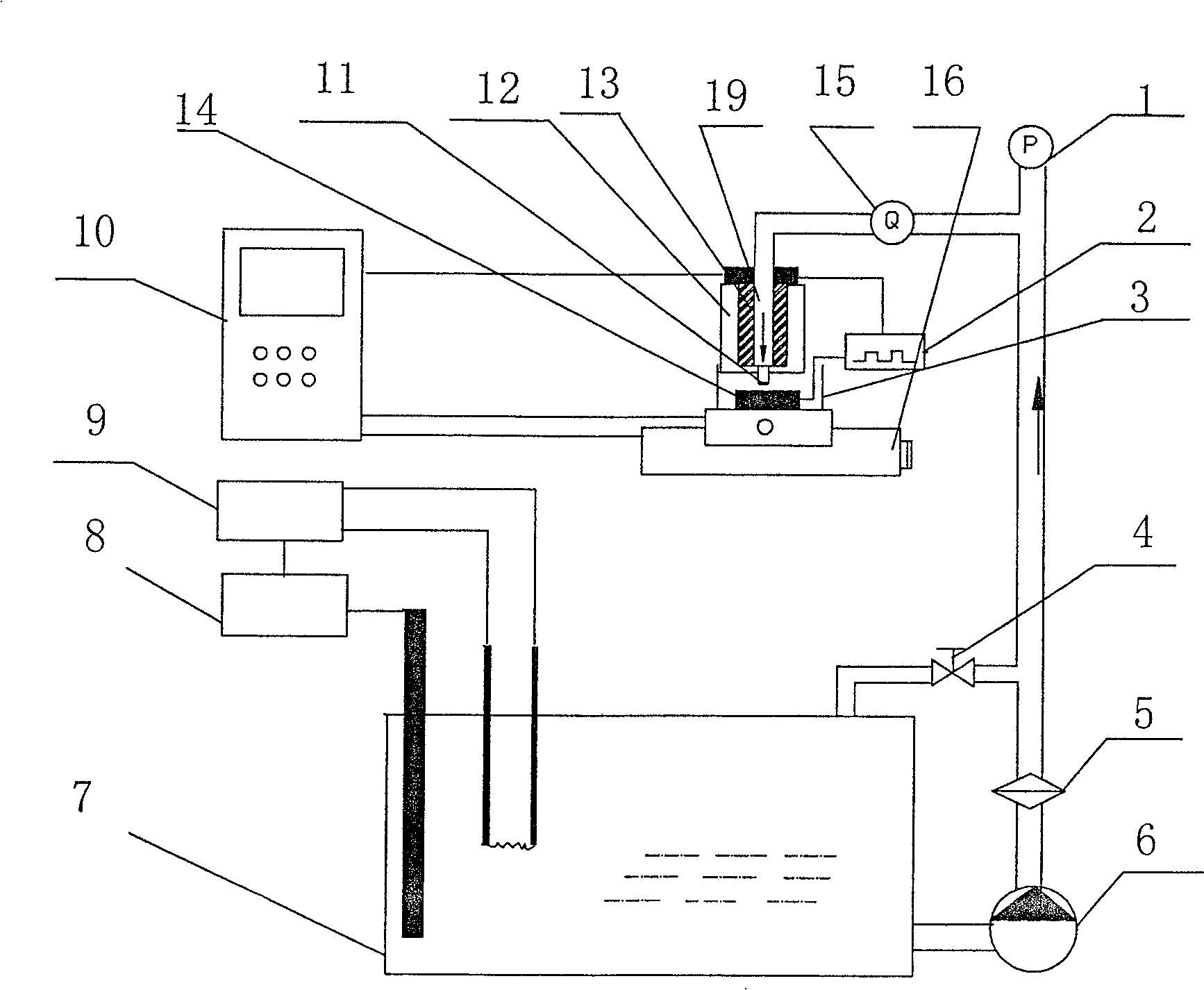

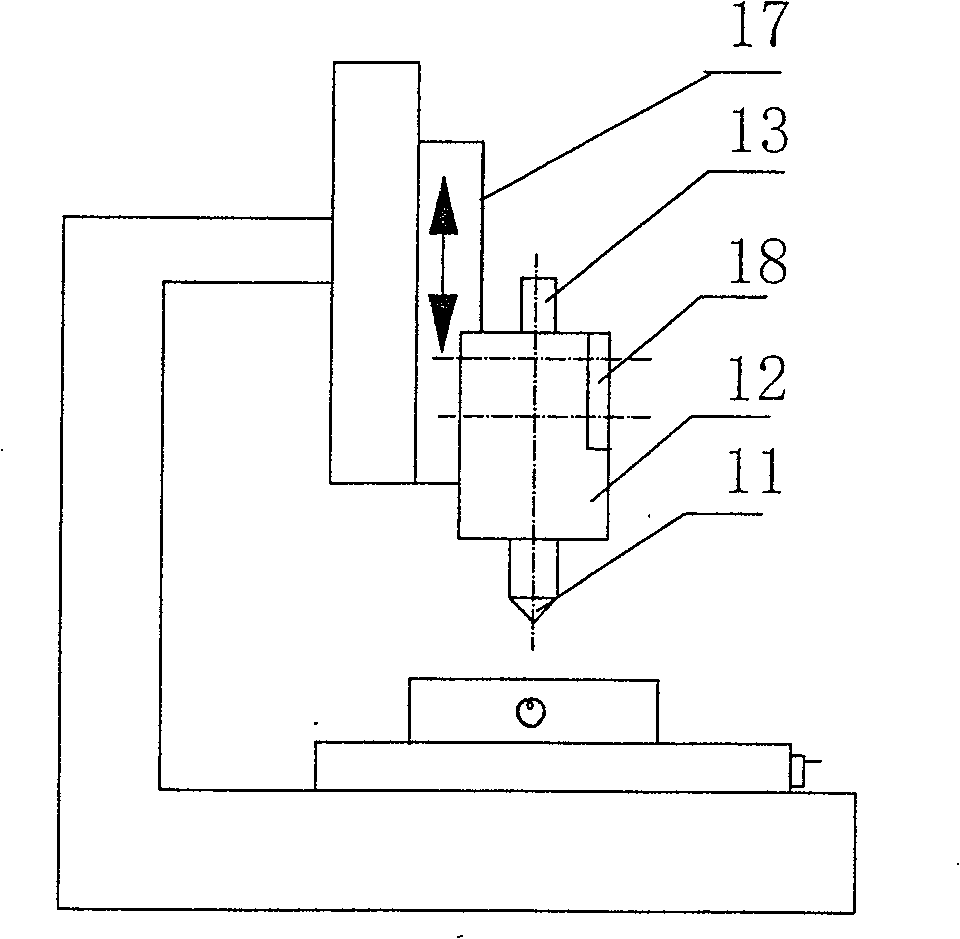

A foam metal and manufacturing method technology, applied in the direction of electroforming, electrolysis, etc., can solve the problems of difficult control of pore diameter, low porosity of pores and pores, complicated process, etc., achieve a large range of pore diameters, increase the limit current density, and thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Stainless steel (1Cr18Ni9Ti) is selected as the cathode plate, and the surface of the plate is sequentially polished, degreased, passivated, washed with water, and dried, and then uniformly deposited on the surface to the expected thickness by spray electrodeposition process.

[0041] Electroforming solution preparation formula (take the preparation of 1000 grams of electroforming solution as an example):

[0042] 250 grams of copper sulfate, 50 grams of sulfuric acid, 1 gram of saccharin (brightener), and the balance of 699 grams is deionized distilled water.

[0043] Metal electrodeposition forming process:

[0044] The shape of the nozzle is long strip, the specification is 1×20mm (depending on the specific situation), the injection speed of the electroforming solution is v=7.5m / s, and the cathode current density is J=250A / dm 2 . During the deposition process, the pH value of the electroforming solution is controlled to be 4, the temperature of the electroforming s...

Embodiment 2

[0048] Stainless steel (1Cr18Ni9Ti) is selected as the cathode plate, and the surface of the plate is sequentially polished, degreased, passivated, washed with water, and dried, and then uniformly deposited on the surface to the expected thickness by spray electrodeposition process.

[0049] Electroforming solution preparation formula (take the preparation of 1000 grams of electroforming solution as an example):

[0050] 250 grams of copper sulfate, 55 grams of sulfuric acid, 1 gram of saccharin (brightener), 0.05 grams of sodium lauryl sulfate (wetting agent), and the balance is 693.95 grams of deionized distilled water.

[0051] Metal electrodeposition forming process:

[0052] The shape of the nozzle is long strip, the specification is 1×20mm (depending on the specific situation), the injection speed of the electroforming solution is v=1.5m / s, and the cathode current density is J=200A / dm 2 . During the deposition process, the pH value of the electroforming solution is con...

Embodiment 3

[0056] Stainless steel (1Cr18Ni9Ti) is selected as the cathode plate, and the surface of the plate is sequentially polished, degreased, passivated, washed with water, and dried, and then uniformly deposited on the surface to the expected thickness by spray electrodeposition process.

[0057] Electroforming solution preparation formula (take the preparation of 1000 grams of electroforming solution as an example):

[0058] 250 grams of copper sulfate, 60 grams of sulfuric acid, 10 grams of thiourea (brightener), NH 4 Cl (buffering agent) 40 grams, sodium lauryl sulfate (wetting agent) 0.2 grams, the balance is 639.8 grams of deionized distilled water.

[0059] Metal electrodeposition forming process:

[0060] The shape of the nozzle is long, the specification is 1×20mm (depending on the specific situation), the injection speed of the electroforming solution is v=7.5m / s, and the cathode current density is J=750A / dm 2 . During the deposition process, the pH value of the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com